The operation of rare earth permanent magnet motors is based on the interaction between the permanent magnets and the motor’s rotor.

When electricity flows through the stator windings, it generates a magnetic field that interacts with the magnetic field created by the rare earth magnets.

This interaction produces torque, causing the rotor to spin and convert electrical energy into mechanical energy.

The design of these motors allows for a more compact and lightweight construction, making them suitable for applications where size and performance are crucial, such as in electric vehicles and small appliances.

The benefits of rare earth permanent magnet motors are numerous. First and foremost, their high efficiency leads to lower energy consumption, which translates into reduced operational costs.

Additionally, these motors are known for their reliability and longevity, often outlasting traditional motors due to fewer moving parts and lower heat generation.

The compact size of rare earth permanent magnet motors also allows for greater design flexibility, enabling manufacturers to create smaller and lighter products without sacrificing performance.

Overall, these advantages make rare earth permanent magnet motors a preferred choice in many industries.

Why Choose a Supplier from China?

Leading Manufacturer in the Industry

China has established itself as a dominant player in the rare earth materials market, making it a hub for suppliers of rare earth permanent magnet motors.

The country’s abundant resources and advanced manufacturing capabilities have allowed it to lead the industry in both production and innovation.

Customers benefit from a wide range of options, including various motor designs and specifications that cater to diverse needs.

This leadership position ensures that buyers can find the latest advancements in motor technology, enhancing their own product offerings.

Cost-Effectiveness

One of the most compelling reasons to choose a supplier from China is the cost-effectiveness of their products.

Due to lower labor and production costs, Chinese manufacturers can offer competitive pricing without compromising quality.

This affordability allows businesses, especially small to medium-sized enterprises, to invest in high-quality rare earth permanent magnet motors that might otherwise be out of reach.

By opting for Chinese suppliers, customers can maximize their budgets while still securing the performance they need.

Access to Advanced Technology

Chinese manufacturers are often at the forefront of technological advancements in motor production.

They invest heavily in research and development to improve the efficiency, performance, and sustainability of their products.

This commitment to innovation means that customers can access cutting-edge motor designs that incorporate the latest technological advancements, such as improved magnet materials and energy-efficient designs.

By partnering with suppliers in China, businesses can ensure they remain competitive in an ever-evolving market.

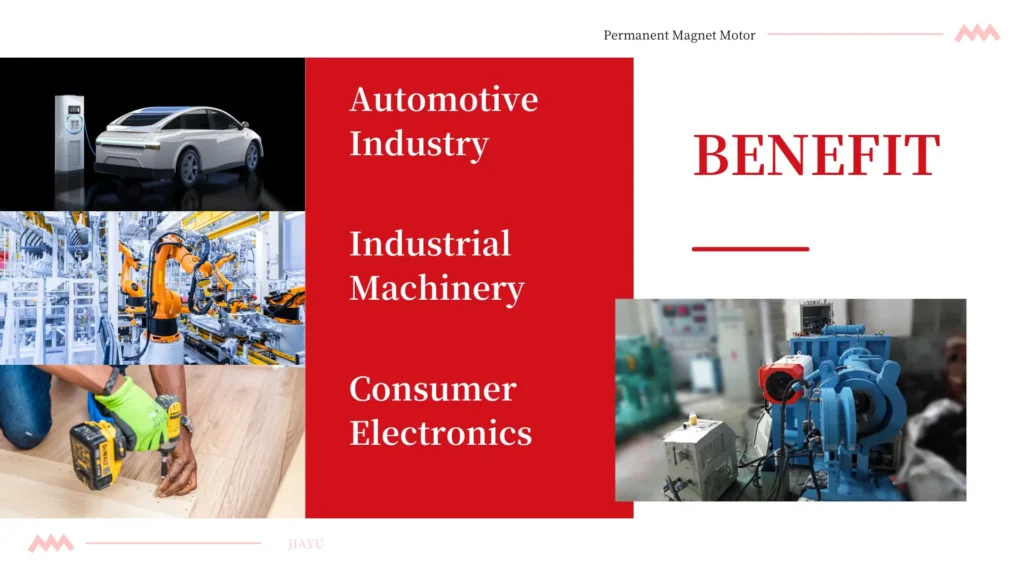

What Applications Benefit from Rare Earth Permanent Magnet Motors?

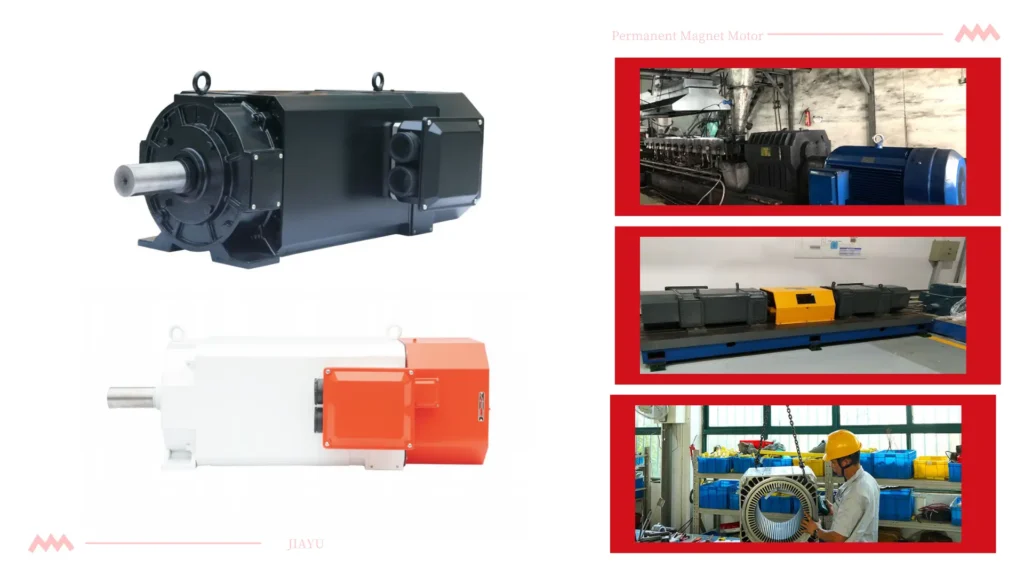

Automotive Industry

In the automotive sector, rare earth permanent magnet motors are increasingly used in electric vehicles (EVs) and hybrid vehicles.

These motors offer higher efficiency and torque compared to traditional motors, enabling better acceleration and overall performance.

As the automotive industry shifts towards electrification, the demand for reliable and efficient motors continues to grow, making rare earth permanent magnet motors a key component in modern vehicle design.

Industrial Machinery

Rare earth permanent magnet motors play a vital role in industrial machinery, where reliability and power are essential.

Applications include robotics, conveyor systems, and precision tools.

The high torque and efficiency of these motors reduce energy costs and improve productivity, making them ideal for demanding industrial environments.

Manufacturers benefit from the consistent performance of these motors, which can enhance operational efficiency and reduce downtime.

Consumer Electronics

Many consumer electronics, such as power tools, home appliances, and personal devices, leverage the compact size and high efficiency of rare earth permanent magnet motors.

Their lightweight design allows for portability while maintaining powerful performance.

For example, in applications such as cordless drills and vacuum cleaners, these motors provide the necessary power without the bulk, enhancing user experience and convenience.

Also Read:

- Permanent Magnet Motor Solutions for Industry in China

- A Comprehensive Guide to Permanent Magnet Synchronous Motor Wholesale in China

How to Identify a Reliable Supplier?

Reputation and Experience

When searching for a supplier, it’s essential to consider their reputation within the industry.

Established companies with a long track record of success are more likely to provide high-quality products and reliable service.

Researching customer reviews, industry certifications, and case studies can give insight into a supplier’s reliability and commitment to excellence.

A reputable supplier will also have a history of meeting customer expectations and delivering products on time.

Quality Assurance Standards

A trustworthy supplier should adhere to stringent quality assurance standards to ensure that their products meet international safety and performance regulations.

Look for suppliers that have certifications such as ISO 9001, which demonstrates a commitment to quality management processes.

These certifications indicate that the supplier has established protocols for monitoring and improving product quality, providing peace of mind to customers regarding their purchases.

Customer Support and Service

Effective customer support is a crucial aspect of any successful supplier relationship.

A reliable supplier should offer comprehensive support, including technical assistance, warranty services, and prompt communication.

Look for suppliers that prioritize customer satisfaction and are responsive to inquiries or concerns.

Good customer service can make a significant difference, especially in complex projects where ongoing support may be needed.

What Should You Consider When Choosing a Motor?

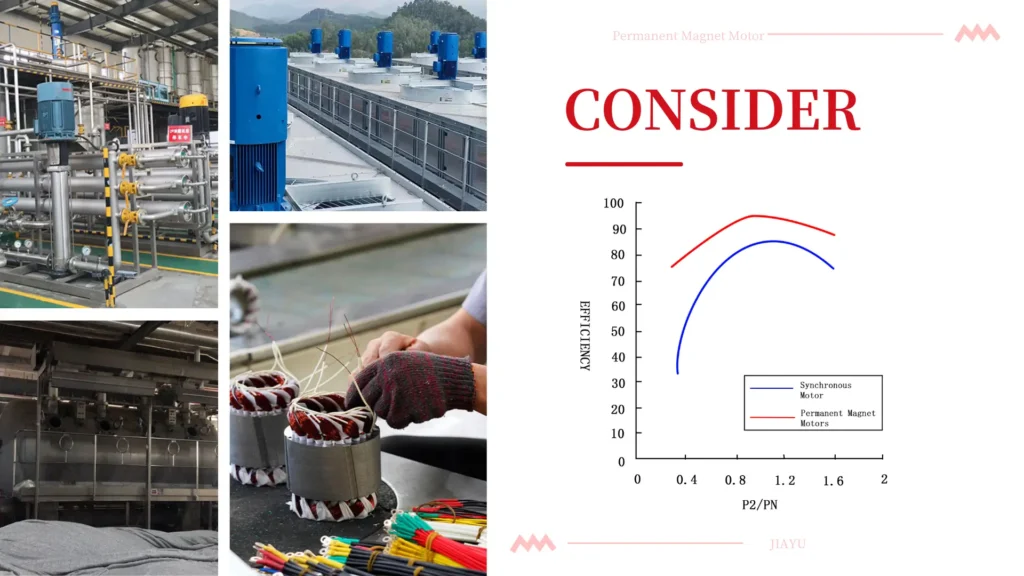

Performance Specifications

When selecting a motor, it’s essential to evaluate its performance specifications, including torque, speed, and efficiency ratings.

Understanding these parameters helps ensure that the motor aligns with your specific application requirements.

For example, a motor with high torque may be necessary for heavy-duty applications, while efficiency ratings can impact energy costs over time.

Assessing these specifications will help you make an informed decision.

Size and Weight

The physical dimensions and weight of the motor are critical factors, especially for applications with space constraints.

Rare earth permanent magnet motors are often more compact than their traditional counterparts, allowing for greater design flexibility.

Consider the available space in your application and ensure that the motor you choose fits well without compromising performance.

A lightweight motor can also enhance portability in applications where mobility is essential.

Cost vs. Value

While price is undoubtedly an important consideration, it’s crucial to assess the overall value of the motor.

A slightly higher initial investment in a quality motor can lead to long-term savings through increased efficiency and durability.

Consider the total cost of ownership, including maintenance and energy consumption, to determine whether the motor will deliver value over its lifespan.

This comprehensive evaluation can lead to smarter purchasing decisions.

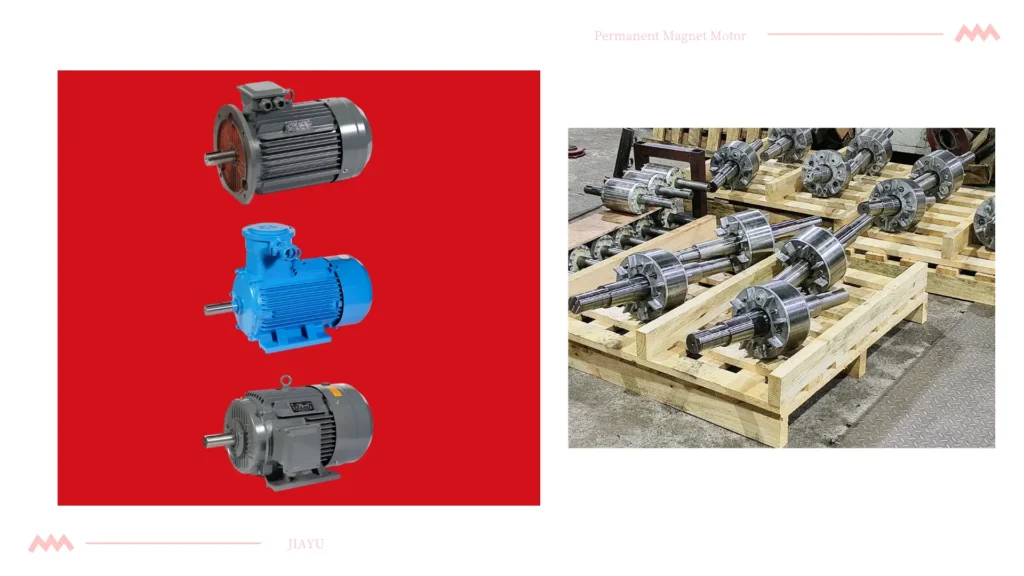

How Are Rare Earth Permanent Magnet Motors Made?

Material Sourcing

The production of rare earth permanent magnet motors begins with sourcing high-quality rare earth materials. Manufacturers need to ensure they are using reliable and sustainable sources to produce their magnets.

This sourcing process is critical, as the quality of the raw materials directly impacts the performance and durability of the final product.

Suppliers that prioritize ethical and sustainable sourcing can differentiate themselves in the market.

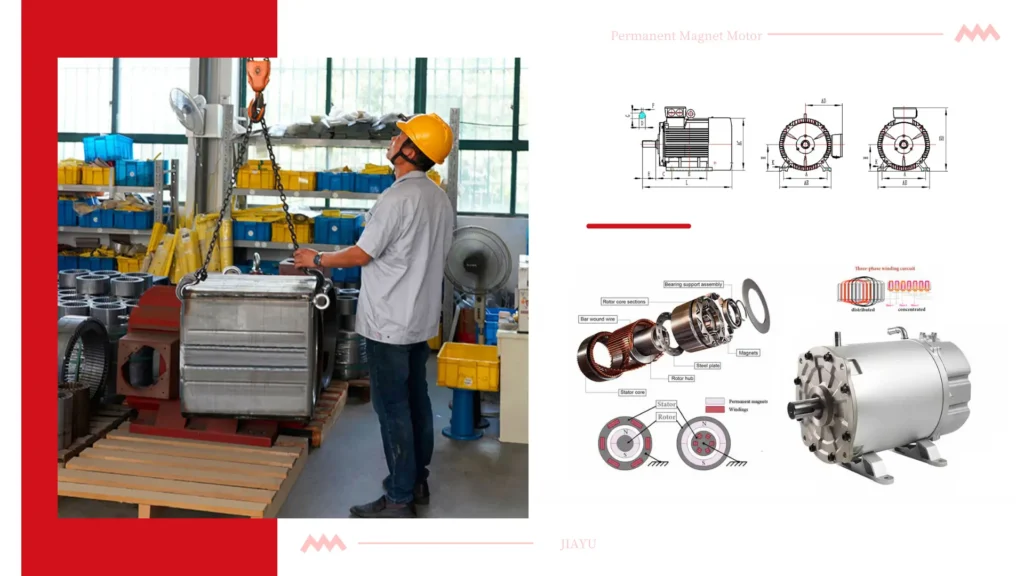

Manufacturing Process

The manufacturing process for rare earth permanent magnet motors involves several key steps, including magnet production, motor assembly, and quality testing.

Each stage is crucial to ensuring the final product meets performance standards.

Advanced manufacturing techniques are often employed to optimize efficiency and precision during production, resulting in high-quality motors that perform reliably in diverse applications.

Quality Control Measures

Quality control is an essential part of the manufacturing process. Suppliers implement rigorous testing protocols to ensure that every motor performs reliably and meets customer expectations.

This may include tests for magnetic strength, thermal performance, and overall efficiency.

By maintaining strict quality control measures, suppliers can provide confidence to their customers that they are receiving products of the highest standard.

What Are the Environmental Considerations?

Sustainability of Rare Earth Materials

The extraction and production of rare earth materials can have environmental impacts, including habitat disruption and pollution.

Responsible suppliers prioritize sustainable practices to minimize ecological damage and promote resource conservation.

By implementing environmentally friendly processes and sourcing materials ethically, suppliers can contribute to a more sustainable future while still meeting market demands.

Energy Efficiency

Rare earth permanent magnet motors are designed to be energy-efficient, which reduces overall energy consumption and lowers carbon footprints.

This efficiency aligns with global efforts to promote sustainable energy use.

As industries seek to reduce their environmental impact, the adoption of energy-efficient technologies like rare earth permanent magnet motors becomes increasingly important.

End-of-Life Recycling

Many manufacturers are exploring recycling options for rare earth materials to reduce waste and promote a circular economy.

This approach not only conserves resources but also mitigates environmental impact.

By implementing recycling programs, suppliers can ensure that their products are not only efficient during use but also environmentally responsible at the end of their lifecycle.

How to Build a Long-Term Relationship with a Supplier?

Open Communication

Establishing open lines of communication with your supplier fosters a strong working relationship.

Regular discussions about needs, expectations, and feedback can lead to improved service and collaboration.

Open communication can also help address any issues that arise, allowing for proactive solutions that benefit both parties.

Continuous Improvement

Engage with suppliers who are committed to continuous improvement. A supplier that values innovation and customer feedback is likely to provide better products and services over time.

By partnering with suppliers that prioritize growth, you can enhance your own operations and stay ahead of industry trends.

Partnership Opportunities

Consider exploring partnership opportunities with your supplier. Collaborating on projects or sharing insights can lead to mutual benefits and a deeper understanding of each other’s needs.

Strong partnerships can lead to innovation and improved product offerings, ultimately enhancing both businesses’ success.

Conclusion

Choosing a reliable rare earth permanent magnet motor supplier in China offers numerous advantages, including access to advanced technology, cost-effectiveness, and a wide range of applications.

These motors provide exceptional performance and efficiency, making them an ideal choice for various industries.

By carefully considering your needs and selecting a reputable supplier, you can enhance your operations and benefit from the many advantages that rare earth permanent magnet motors have to offer.

Investing in quality motors today will lead to improved performance and sustainability in the future.