Permanent magnet motors are electric motors that utilize permanent magnets made from rare earth materials or ferrite to generate torque.

Unlike traditional motors that rely on electromagnetic coils to create a magnetic field, these motors harness the intrinsic magnetic properties of permanent magnets.

This fundamental difference results in significantly enhanced performance and efficiency, making them a preferred choice across various industrial applications.

The use of permanent magnets eliminates the need for continuous power to generate a magnetic field, allowing these motors to operate more efficiently.

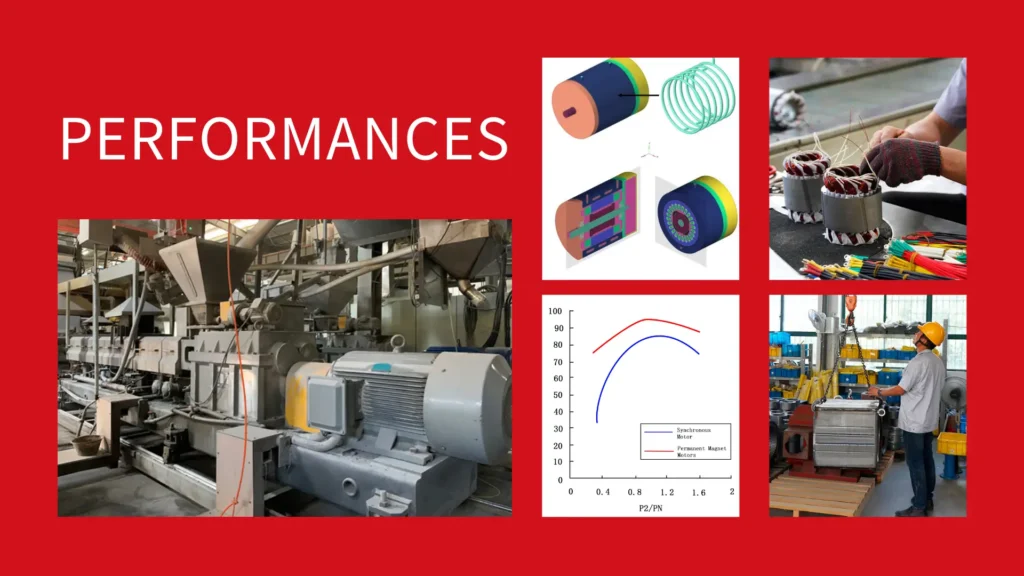

The primary components of a permanent magnet motor include the rotor, stator, and the permanent magnets themselves.

The arrangement and strength of the magnets are critical factors that influence the motor’s efficiency, power output, and overall performance.

Understanding these components helps in selecting the right motor for specific applications.

Why Choose Permanent Magnet Motors for Industrial Applications?

High Efficiency

One of the most significant advantages of permanent magnet motors is their high efficiency.

These motors can convert a greater percentage of electrical energy into mechanical energy compared to traditional induction motors.

This increased efficiency leads to lower energy consumption, which is particularly beneficial for industries looking to reduce operational costs.

Enhanced efficiency not only translates into financial savings but also contributes to reduced environmental impact by minimizing energy waste.

Compact Design

Permanent magnet motors are typically smaller and lighter than their traditional counterparts, making them ideal for applications where space is at a premium.

This compact design allows for greater flexibility in installation and can help optimize the overall layout of machinery.

The smaller size also means that businesses can achieve higher power density, providing the same or greater output while occupying less physical space.

This is particularly advantageous in industries that require high-performance equipment in constrained environments.

Low Maintenance Requirements

Due to their fewer moving parts and simple design, permanent magnet motors require less maintenance than traditional motors.

This reliability translates to reduced downtime and maintenance costs, allowing businesses to operate more efficiently.

With fewer components that can wear out or require replacement, these motors often enjoy longer lifespans, further enhancing their appeal.

This low maintenance requirement allows companies to allocate resources more effectively, focusing on production and innovation rather than upkeep.

What Industries Benefit Most from Permanent Magnet Motors?

Manufacturing

The manufacturing sector is one of the largest beneficiaries of permanent magnet motors.

These motors are commonly used to power machinery such as conveyor belts, robotic arms, and CNC machines.

Their efficiency and reliability enhance productivity in high-demand environments, allowing for faster production rates and improved consistency in manufacturing processes.

As industries increasingly adopt automation and advanced manufacturing techniques, the role of permanent magnet motors becomes even more critical.

Automotive

In the automotive industry, the demand for permanent magnet motors is rapidly growing, especially with the rise of electric vehicles (EVs) and hybrid vehicles.

These motors provide higher torque and efficiency, contributing to improved acceleration and overall vehicle performance.

Their lightweight design allows for better energy management, extending battery life and range in electric vehicles.

As the automotive sector continues to pivot towards electrification, permanent magnet motors will play a pivotal role in shaping the future of transportation.

Renewable Energy

Permanent magnet motors are also essential in renewable energy applications, particularly in wind turbines and solar tracking systems.

Their ability to operate efficiently at varying speeds makes them suitable for harnessing energy from natural sources.

In wind turbines, for example, these motors can optimize energy capture even in low-wind conditions, enhancing energy generation.

By integrating permanent magnet motors into renewable energy systems, businesses can contribute to a more sustainable energy future.

Also Read:

- PMSM Motor for Industrial Use in China

- China-Made Permanent Magnet Motors for High-Torque Industrial Machinery

How to Select the Right Permanent Magnet Motor?

Performance Requirements

When choosing a permanent magnet motor, it’s crucial to consider the specific performance requirements of your application.

Factors such as torque, speed, and power output must align with the demands of the machinery or equipment being used.

Understanding these parameters ensures that the motor can operate effectively and efficiently within the intended application.

Collaborating with engineers or specialists can help identify the best fit for your needs.

Size and Weight Constraints

Evaluate the physical dimensions and weight constraints of your installation space.

Permanent magnet motors are often more compact, but it’s vital to ensure that the chosen motor fits well without compromising performance.

In applications where space is limited, selecting a motor that optimally utilizes available space can lead to significant operational advantages.

Consideration of weight is also essential for mobile applications where portability is a requirement.

Budget Considerations

Cost is a significant factor when selecting any industrial equipment. While permanent magnet motors may have a higher initial purchase price compared to traditional motors, their efficiency and low maintenance costs can lead to substantial long-term savings.

Conducting a thorough cost-benefit analysis can help determine whether the investment in a permanent magnet motor will yield a favorable return over time.

This analysis should take into account energy savings, reduced maintenance, and overall operational efficiency.

What Are the Advantages of Sourcing from China?

Competitive Pricing

China stands as a leading manufacturer of permanent magnet motors, offering competitive pricing due to lower labor and production costs.

This affordability enables businesses, particularly small to medium-sized enterprises, to access high-quality motors without overspending.

By sourcing from China, companies can maximize their budgets while ensuring they receive reliable and efficient products that meet their operational needs.

Wide Range of Options

Chinese manufacturers provide a diverse selection of permanent magnet motors tailored to various industrial applications.

This wide array of options ensures that businesses can find the right motor to meet their specific requirements, whether they are looking for high torque, compact size, or specific performance characteristics.

The availability of different designs and specifications allows companies to customize their solutions effectively.

Advanced Manufacturing Techniques

Many suppliers in China utilize state-of-the-art manufacturing techniques and technologies, resulting in high-quality products that meet international standards.

These advanced production processes ensure that permanent magnet motors are built to last and perform reliably under demanding conditions.

Partnering with manufacturers that prioritize innovation and quality can enhance a business’s reputation and operational efficiency.

And More:

- Top 10 Permanent Magnet Synchronous Motor Manufacturers in China

- High-Performance Permanent Magnet Motors Made in China for Commercial Applications

What Should You Know About Quality Assurance?

Importance of Quality Standards

When sourcing permanent magnet motors, it’s essential to choose suppliers that adhere to strict quality assurance standards.

Certifications such as ISO 9001 indicate a commitment to quality management and production excellence.

Suppliers that prioritize quality assurance are more likely to deliver reliable products that meet customer expectations and industry regulations.

Testing and Validation

Reputable manufacturers conduct rigorous testing and validation of their motors to ensure they meet performance specifications.

Thorough testing may include assessments of efficiency, thermal performance, and durability under various operating conditions.

Look for suppliers that provide detailed reports and documentation of their testing processes, as this transparency demonstrates their dedication to quality and reliability.

Warranty and Support

A solid warranty and reliable customer support are essential when selecting a motor supplier.

Ensure that the manufacturer offers a comprehensive warranty that covers potential defects or issues.

Good customer support can provide assistance during installation and maintenance, enhancing the overall customer experience.

Knowing that support is available can give businesses added confidence in their purchase.

How Do Permanent Magnet Motors Contribute to Sustainability?

Energy Efficiency

Permanent magnet motors are designed to be highly energy-efficient, which significantly reduces energy consumption in industrial applications.

This efficiency not only lowers operational costs but also contributes to environmental sustainability by minimizing carbon footprints.

As industries strive to meet sustainability goals, the adoption of energy-efficient technologies like permanent magnet motors becomes increasingly important.

Reduced Waste

With fewer moving parts, permanent magnet motors generate less waste over their lifetimes.

Their longevity and durability mean that they require replacement less frequently, further reducing waste and the need for disposal.

This aspect of sustainability aligns with the growing emphasis on environmental responsibility in manufacturing and energy consumption.

Supporting Renewable Energy

By powering renewable energy systems, permanent magnet motors play a crucial role in promoting sustainable energy solutions.

Their efficient operation in wind turbines and solar applications helps harness natural resources, contributing to a greener future.

The integration of these motors into renewable energy technologies supports efforts to transition to cleaner, more sustainable energy sources.

How to Build a Long-Term Relationship with Your Supplier?

Open Communication

Establishing open and transparent communication with your supplier is vital for a successful partnership.

Regular discussions about needs, expectations, and feedback can lead to improved service and collaboration.

Keeping lines of communication open encourages trust and ensures that any issues can be addressed promptly.

Feedback and Collaboration

Providing feedback on the motors and services you receive is essential for building a strong relationship.

Engaging in collaborative efforts with your supplier can lead to continuous improvement and innovation.

Suppliers that value customer input are more likely to adapt their offerings to better meet your needs.

Future Planning

Consider discussing future projects and needs with your supplier. A long-term partnership can lead to better pricing, customized solutions, and priority service for upcoming projects.

This proactive approach can enhance your operational efficiency and resource management, ultimately benefiting both parties.

Conclusion

Permanent magnet motor solutions are transforming industries across China and the globe.

Their high efficiency, compact design, and low maintenance requirements make them an ideal choice for various applications, from manufacturing to renewable energy.

By selecting the right supplier and understanding the unique advantages of these motors, businesses can enhance their productivity and contribute to sustainable practices.

Investing in permanent magnet motors today will lead to improved performance and efficiency in the future.