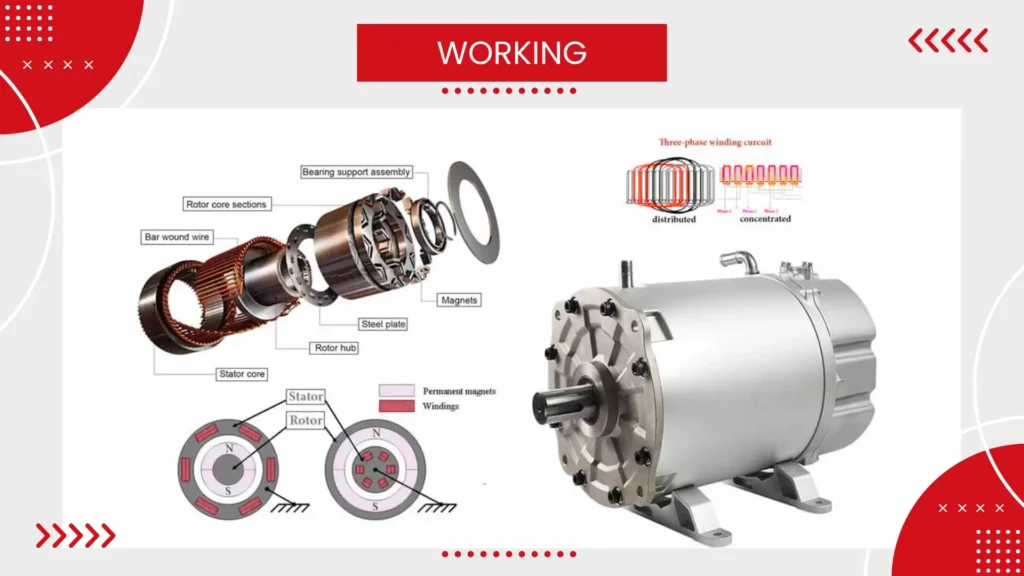

Permanent Magnet Synchronous Motors – PMSMs – are electric motor type. They use permanent magnets to create magnetic field.

Traditional motors rely on electromagnets. Contrastingly, PMSMs use natural magnetism of permanent magnets.

This results in highly efficient and effective way of converting electrical energy. The conversion is done into mechanical power.

Today’s fast-paced industrial landscape has seen surge in demand. This is for compact, reliable and efficient motors.

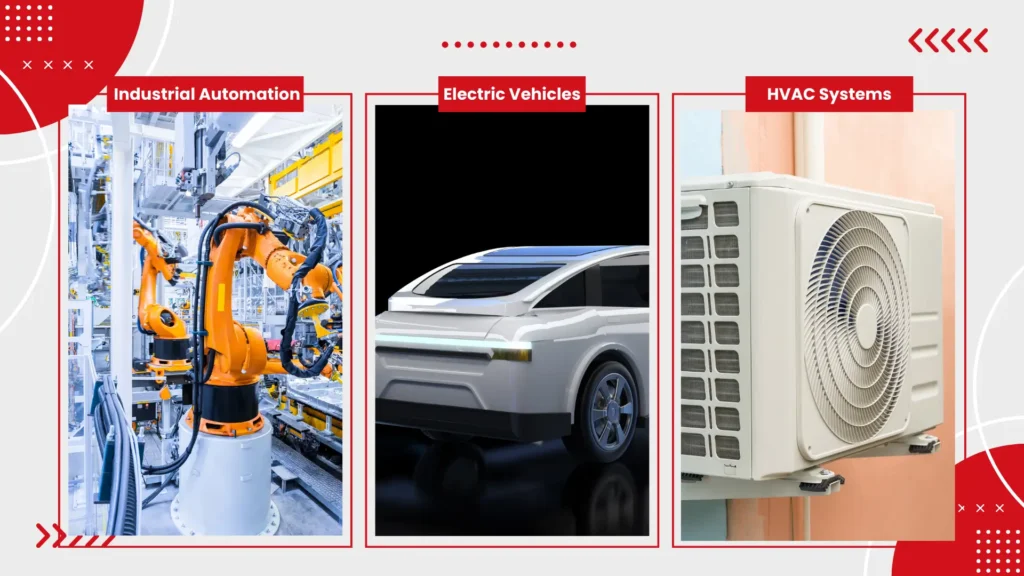

PMSMs play crucial role in many sectors. These include manufacturing and automation. They extend to consumer electronics.

Their ability to deliver high performance stands out. At the same time they minimize energy consumption. This combination makes them preferred choice for many modern applications.

LearnMore:

A Comprehensive Guide to Permanent Magnet Synchronous Motor Wholesale in China

Key Feature 1: High Efficiency

Energy Savings

One of the most significant advantages lies in PMSMs. The motors boast high efficiency. They can achieve levels over 90%.

This is a significant outperformance of traditional induction motors. Efficiency translates into substantial energy savings.

This makes them ideal. Businesses looking to reduce electricity bills will find them appealing.

Reduced Operational Costs

Long-term benefits of PMSMs are significant. Initial investment may be high compared to conventional motors.

However, the reduced energy consumption results in lower operational costs. Over time savings can offset initial purchase price. This provides excellent return on investment.

Sustainability Benefits

In era of increasing environmental awareness PMSMs offer sustainability benefits. These benefits are hard to ignore. Their energy consumption is lower. This results in a reduced carbon footprint.

PMSMs become an attractive option for companies. Companies that strive to meet environmental regulations. Companies wanting to improve their sustainability profiles.

Key Feature 2: Compact Design

Space-Saving Advantages

PMSMs are designed to be compact and lightweight. This makes them ideal for situations where space is a premium.

Their small footprint enables easy integration into tight spaces. Spaces like robotics or small machinery. This does not compromise their performance.

Lightweight Construction

PMSMs have a lightweight nature. This nature not only aids in installation it also improves their use in mobile applications.

This is especially useful in industries like automotive and aerospace. Here, weight reduction is vital for efficiency.

Versatility in Design

PMSMs can be customized to meet special needs. These needs can include a wide range of requirements for integration into unique systems. Hence, manufacturers can shape PMSMs to fit specific requirements.

This flexibility empowers engineers to create solutions more effectively. The solutions are designed for applications that are particularly unique.

Key Feature 3: Superior Performance

High Torque Density

PMSMs display high torque density. This implies they deliver more torque per unit weight. In comparison traditional motors fall short. Characteristic is vital for certain applications.

Applications that demand quick acceleration. Applications that demand high performance. Such applications include electric vehicles and industrial machinery.

Excellent Speed Control

PMSMs provide precise speed control. Their advanced design sets them apart. This makes them ideal for automation and robotics.

Capabilities allow for smoother operation. Meshes well with a range of applications. This range includes conveyor systems to CNC machines.

Low Noise Operation

PMSMs boast quiet operation. This is a significant advantage in residential and commercial settings.

Noise levels are low, contributing to user comfort. Particularly valued in applications like HVAC and consumer appliances.

Key Feature 4: Low Maintenance Requirements

Fewer Moving Parts

One standout characteristic of PMSMs is design. It features fewer moving parts than standard motors.

This simplicity equals to enhanced reliability. It reduces wear and tear, contributing to less frequent maintenance. The need for repairs is also minimized.

Long Lifespan

On the whole PMSMs often exhibit a longer lifespan. This is in comparison to traditional motors.

Sturdy construction and less mechanical stress are the reasons. This durability makes them an economical option. For businesses, they serve as viable long-term solutions.

Ease of Service

During maintenance PMSMs are simpler to service. Their design is straightforward.

This ease in service reduces downtime. This advantage allows businesses to maintain productivity. The interruptions are significant.

Key Feature 5: Wide Range of Applications

Industrial Uses

PMSMs find widespread usage in industrial settings. Their efficiency and reliability support improved production processes.

These applications vary from assembly lines to automated manufacturing systems. This highlights their versatility.

Commercial Applications

PMSMs are present in HVAC systems. Also they are found in elevators and escalators.

They enhance the comfort of users. They increase the convenience and reduce operational costs. PMSMs are known for their energy efficiency.

Consumer Electronics

There is a significant increase in use of PMSMs in consumer electronics. PMSMs are key part of products like energy-efficient washing machines. They are also used in quiet ceiling fans.

PMSMs help manufacturers. They aid in creating products that appeal. These products cater to environmentally conscious consumers.

Key Feature 6: Enhanced Control Capabilities

Advanced Technology Integration

PMSMs integrate with advanced technologies. Sensors and feedback systems are included.

This allows for real-time monitoring. It also enables adjustments. This capability improves overall system performance and reliability.

Flexible Operation Modes

PMSMs come with operation modes. Various options are available. They include variable speed drives.

These drives allow for performance tailored to specific tasks. Such flexibility offers a chance for businesses.

They can optimize motor operation. This optimization is based on their unique needs.

Smart Connectivity

The Internet of Things (IoT) is becoming more prominent. PMSMs can be integrated with smart connectivity.

This feature lets users operate their motor from a distance. It also allows for diagnostics.

Thus users get greater control. They also gain better insight into their motor systems.

Product Recommend:

- Three-phase Permanent Magnet Synchronous Motor

- Three-phase Explosion-proof Permanent Magnet Synchronous Motor

- Three-phase Rare Earth permanent magnet synchronous Motor

- Three-phase Water-cooling Permanent Magnet Synchronous Motor

Key Feature 7: Robust Performance in Harsh Conditions

Temperature Tolerance

PMSMs are engineered to function efficiently in extreme temperatures. This makes them suitable for outdoor applications.

It also allows them to endure conditions where regular motors might fail.

Resistance to Vibration

These motors maintain stability under dynamic loads. They show superb resistance to vibration.

This quality is particularly advantageous in heavy machinery. It’s also beneficial in industrial applications where continuous performance is vital.

Protection from Contaminants

PMSMs can be constructed with protection from dust and humidity. This extends lifespan and functionality.

It makes their operation in challenging environments easier. This robustness makes them an ideal choice. It is excellent for use in harsh industrial settings.

Key Feature 8: Cost-Effectiveness

Initial Investment vs. Long-Term Savings

The costs that come up front for Permanent Magnet Synchronous Motors or PMSMs may be more.

This is when you compare with traditional motors. Yet, the long-term savings PMSMs generate is significant.

Savings stem from economies in the energy and the maintenance realms. Incorporating PMSMs results in a cost-efficient answer.

Businesses should remember this. When determining which motor options to go with, they must calculate the whole lifecycle costs.

This includes the cost of initial investment and ongoing expenses. This way they can get an accurate picture of the economic benefits of PMSMs.

Financing Options

There are different funding options. These can be incentives from governmental entities. They can also come in the form of refunds. These can help lessen the initial investment in PMSMs.

Exploration of these options can lead to a smoother transition. It can make the switch to more efficient options more practical.

Market Trends

The surge in use of PMSMs showcases a shift. This shift is towards energy-saving technologies. PMSMs are infiltrating numerous industries. Price dynamics are shifting.

They becoming more in favor. This makes PMSMs a wise choice for businesses of any size.

Conclusion

In a nutshell Permanent Magnet Synchronous Motors present multiple pluses. They come with high efficiency. They offer a compact design. They deliver superior performance.

They have low maintenance requirements. All these facets make PMSMs an alluring choice. They cater to a broad spectrum of applications.

For businesses aiming to boost their operational efficiency considering PMSMs is wise choice.

Their advanced capabilities make them an attractive option. They have proven benefits to offer. PMSMs are expected to take on a significant role. It will be in the future of motor technology.

For potential buyers seeking more information and purchasing options it is recommended.

They explore reputable suppliers. Manufacturers should be considered. They specialize in PMSM technology.