In many industrial and commercial settings, equipment rarely operates at a single, steady speed.

From conveyor belts handling fluctuating product volumes to pumps adjusting to changing fluid demands, workloads can shift dramatically in seconds.

This variability demands a motor that can keep up—one that can slow down gently, speed up smoothly, and maintain efficiency across the entire range. Wide-speed range rare earth permanent magnet synchronous motors (PMSMs) are engineered to do exactly that.

Let’s explore how they achieve this flexibility, why it matters for your operations, and how they can elevate your system’s efficiency.

What Does “Wide-Speed Range” Mean for Practical Applications?

Defining speed range in real-world terms

A wide-speed range refers to a motor’s ability to operate effectively at very low speeds (sometimes just a few rotations per minute) and quickly ramp up to much higher speeds—often hundreds or thousands of rotations per minute—without losing performance.

This versatility isn’t just about speed itself but about maintaining precision, such as ensuring a bottling line fills containers accurately whether moving at 10 RPM or 500 RPM.

Why flexibility matters more than maximum speed alone

A motor that can reach extremely high speeds but struggles to slow down or maintain low speeds is limited in practical use.

Variable workloads require a motor that excels at both ends of the spectrum, ensuring smooth transitions and consistent output whether demand is high or low.

A packaging machine might need to slow to a near-stop to align labels perfectly, then race to meet a production quota—something a “one-speed” motor could never achieve without sacrificing quality.

How speed range aligns with variable workloads

Workloads rarely follow a set schedule. A sudden spike in production, a drop in material supply, or a shift in process requirements can change the required speed in an instant.

A wide-speed range motor adapts to these shifts automatically, eliminating the need for manual adjustments or costly system overrhauls.

This alignment is particularly critical in industries like food processing, where production batches vary in size, or logistics, where conveyor traffic fluctuates with shipping schedules.

And More:

How to choose the right pmsm motor for different applications?

How Do Rare Earth Materials Enable This Wide-Speed Capability?

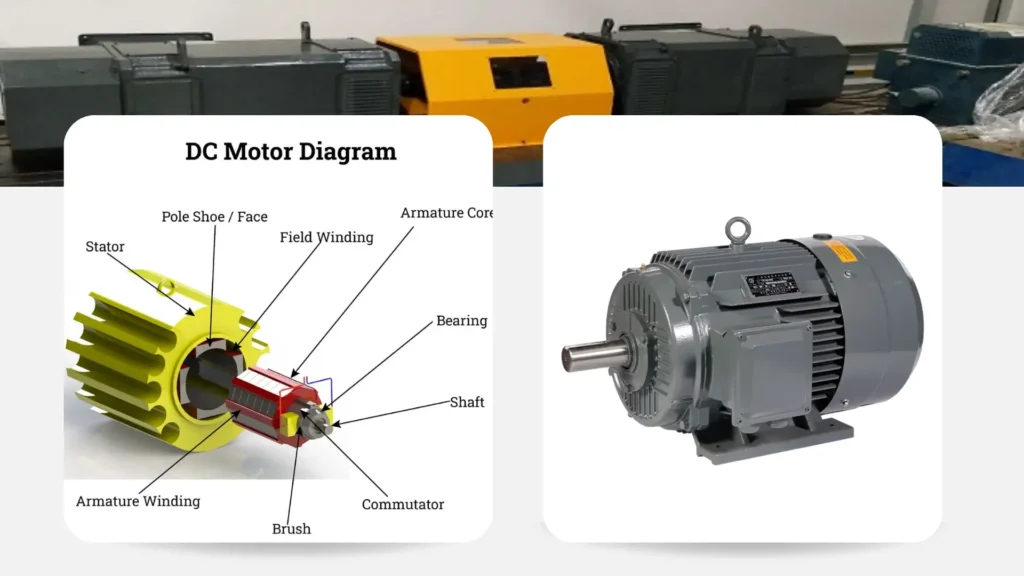

The role of strong magnets in speed control

Rare earth magnets generate intense, stable magnetic fields. This strength allows the motor to produce torque efficiently at low speeds, where weaker magnets would struggle, and maintain that efficiency as it speeds up.

The result is consistent performance across the entire speed spectrum.

Which lose magnetic strength at high temperatures, rare earth magnets retain their potency even under the thermal stress of rapid speed changes.

Reducing energy loss at both low and high speeds

Traditional motors often waste energy at extreme speeds—either through heat at high speeds or inefficiency at low speeds.

Rare earth PMSMs minimize this loss because their strong magnetic fields allow for precise control of electrical input, matching energy use to the required speed and reducing waste.

This precision is especially valuable in 24/7 operations, where even small energy savings per hour accumulate into significant annual reductions.

Enhancing stability during speed transitions

Switching between speeds can cause vibrations or instability in less advanced motors, leading to wear and tear or product damage.

Rare earth PMSMs use their magnetic precision to smooth out these transitions, ensuring acceleration and deceleration feel seamless, even when changing speeds quickly.

This stability is crucial for delicate applications, such as semiconductor manufacturing, where vibrations could compromise microchip quality.

Why Is Adaptability to Variable Workloads Critical for Efficiency?

Avoiding energy waste during low-demand periods

In systems with fixed-speed motors, energy is often wasted during slow periods. For example, a pump might run at full speed even when only a small amount of fluid is needed, consuming more electricity than necessary.

A wide-speed range motor slows down, using only the energy required for the current workload.

This not only cuts utility costs but also aligns with global sustainability goals, reducing a facility’s carbon footprint.

Preventing overload during high-demand spikes

When workloads surge, fixed-speed motors may struggle to keep up, leading to overheating or system failures.

A wide-speed range motor can accelerate to meet the demand, distributing the load evenly and preventing strain on components.

This resilience is vital in industries like manufacturing, where a single motor failure could halt an entire production line, costing thousands in downtime.

Reducing wear from frequent speed adjustments

Motors that aren’t designed for variable speeds can suffer from increased wear when forced to switch speeds often.

The smooth transitions of rare earth PMSMs minimize friction and stress, extending the motor’s lifespan and reducing maintenance needs.

In a warehouse with automated guided vehicles (AGVs), frequent starts and stops would quickly degrade a standard motor, but a wide-speed range PMSM remains reliable for years longer.

What Makes These Motors Different from Standard PMSMs in Speed Handling?

Broader speed spectrum without performance drops

Standard PMSMs may perform well within a narrow speed range but lose efficiency or torque at very low or high speeds.

Wide-speed range rare earth PMSMs are optimized to maintain torque and precision across a much wider spectrum, ensuring no loss of performance at either extreme.

A standard PMSM might struggle to power a crane lifting heavy loads at slow speeds, while a rare earth model handles it effortlessly.

Faster response to speed change commands

When a system signals a need for speed adjustment (e.g., a sensor detecting more material on a conveyor), standard motors may lag.

Wide-speed range rare earth PMSMs react almost instantly, thanks to their strong magnetic fields and advanced control systems, ensuring the change happens exactly when needed.

This rapid response is critical in time-sensitive processes, such as pharmaceutical packaging, where timing errors can lead to product recalls.

Superior torque retention at low speeds

Low-speed operation often exposes weaknesses in motors—they may struggle to generate enough torque to move heavy loads slowly.

Rare earth PMSMs retain their torque even at low speeds, making them ideal for tasks like gently moving fragile items or maintaining tension in material handling.

In textile manufacturing, consistent low-speed torque ensures yarns aren’t stretched or broken during weaving.

Also Read:

- Rare Earth PMS Motors vs. Induction Motors: Torque Characteristics

- Key Features of Permanent Magnet Synchronous Motors (PMSMs)

- Buying Under 1,750 RPM Custom PMSM Motors in China

Can Wide-Speed Range Rare Earth PMSMs Handle Heavy Loads at Any Speed?

Torque consistency across the speed spectrum

Torque—the force that moves loads—is critical, regardless of speed. These motors deliver consistent torque whether they’re running at 10 RPM or 1,000 RPM, ensuring heavy loads are moved smoothly at any speed.

This consistency is a game-changer in industries like construction, where cranes must lift heavy steel beams at both slow, controlled speeds and faster, efficient rates.

How rare earth magnets support high-load performance

The strong magnetic fields from rare earth materials allow the motor to generate more torque with less energy, even when speeds are low.

This means it can handle heavy loads without straining, avoiding the overheating or slowdowns common in other motors.

A rare earth PMSM powering a mining conveyor can move tons of ore at low speeds during sorting and then speed up to transport it efficiently—all without compromising on power.

Preventing stalling during sudden load shifts

A sudden increase in load can cause other motors to stall. Wide-speed range rare earth PMSMs adjust their torque output instantly to counteract the shift, keeping the system moving without interruption.

This anti-stall capability is essential in waste management, where pumps often handle varying densities of sludge, preventing costly clogs and downtime.

How Do These Motors Integrate with Systems That Need Speed Flexibility?

Compatibility with common speed control systems

Most industrial systems use standard controllers to adjust speed.

Wide-speed range rare earth PMSMs are designed to work seamlessly with these systems, requiring no specialized equipment or complex programming to operate.

This plug-and-play compatibility makes retrofitting existing systems straightforward, allowing businesses to upgrade without overhauling their entire infrastructure.

Easy calibration for specific workload patterns

Every operation has unique workload rhythms—some may have predictable peaks and valleys, while others are more random.

These motors can be calibrated to match your specific patterns, ensuring they respond optimally to the speed changes your system experiences most often.

A bakery with morning and evening production rushes can program the motor to anticipate these peaks, ensuring smooth transitions without manual input.

Adaptation to both manual and automated commands

Whether speed adjustments are triggered by a worker pressing a button or an automated sensor, these motors respond consistently.

They integrate with both manual controls and smart systems, making them versatile for any operation, from legacy setups to cutting-edge automated facilities.

In a smart factory, for instance, they can sync with IoT sensors to adjust speeds in real time based on live production data, further boosting efficiency.

And More:

- High-Torque Applications: Elevating Robotics with Permanent Magnet Synchronous Motors

- Permanent Magnet Synchronous Motor Comparison

- Enhancing Grid Stability: Rare Earth PMS Motors in Energy Storage Systems

What Are the Benefits of Smooth Speed Transitions in Daily Operations?

Reducing stress on connected equipment

Abrupt speed changes can jolt gears, belts, and other components, leading to premature wear.

Smooth transitions minimize this stress, extending the lifespan of the entire system and reducing the need for replacements.

In a printing press, sudden speed shifts can damage rollers or misalign paper, but smooth transitions with a rare earth PMSM ensure consistent print quality and longer equipment life.

Improving product and material handling safety

Fragile items (like glassware or electronics) can be damaged by sudden starts or stops.

Smooth speed changes ensure materials are moved gently, reducing the risk of breakage and improving overall product quality.

In the automotive industry, for instance, transporting delicate circuit boards requires precise, jolt-free movement—something these motors deliver reliably.

Learn more:Permanent Magnet Motors in the Textile Industry: Application&Advantages

Lowering noise levels in the workplace

Jerky speed adjustments often create more noise, as components shift abruptly.

The seamless transitions of wide-speed range rare earth PMSMs result in quieter operation, creating a more comfortable and productive work environment.

This is particularly beneficial in settings like indoor warehouses or manufacturing plants, where excessive noise can lead to employee fatigue or hearing damage.

Why Should Businesses Prioritize Wide-Speed Range Motors for Variable Workloads?

Long-term cost savings through energy efficiency

By using only the energy needed for the current speed and workload, these motors reduce electricity bills significantly over time.

For operations with frequent speed changes, the savings can add up to thousands of dollars annually.

Lower energy use often qualifies businesses for green energy incentives or tax breaks, further enhancing their return on investment.

Increased operational flexibility for changing demands

Businesses rarely stay static—product lines expand, processes evolve, and customer demands shift.

A wide-speed range motor adapts to these changes, eliminating the need to replace motors when workloads or speeds requirements change.

This flexibility future-proofs your operations, allowing you to scale up or pivot without costly equipment upgrades.

Reduced downtime from motor-related issues

Motors that struggle with variable speeds are more likely to fail, leading to costly downtime.

The durability and adaptability of wide-speed range rare earth PMSMs minimize these failures, ensuring your system stays up and running when you need it most.

For a distribution center handling time-sensitive shipments, this reliability can mean the difference between meeting delivery deadlines and losing customers.

Conclusion

In a world where workloads are rarely constant, the ability to adapt is key to efficiency and reliability.

Wide-speed range rare earth PMSMs offer exactly that—seamless speed transitions, consistent performance across all ranges, and the strength to handle variable loads with ease.

These motors aren’t just components; they’re strategic assets that empower businesses to thrive in dynamic environments.

Investing in a wide-speed range rare earth PMSM isn’t just about upgrading a component—it’s about future-proofing your operations for whatever demands come next.