Permanent magnet motor (PMM) essentially is a motor which functions on the laws of electromagnetic induction.

The core of the motor has a certain number of windings through which a current flows.

When these two forces interact, a motion of rotation, energy conversion from electric to mechanical takes over.

PMMs have become fundamental in modern technology due to their existence and importance in society.

Their enhanced performance can ensure minimum energy wastage in a time where energy is considered very expensive.

Being easily portable, the tiny motors have found applications in a variety of areas ranging from items used at home to heavy machines in factories.

It is thus an economic investment as it enhances productivity while reducing the cost of operating equipment due to the low maintenance cost of the PMMs.

Types of Permanent Magnet Motors

AC Permanent Magnet Motors

Alternating current (AC) permanency magnet synchronous motors have designed for the utility of an alternating current.

Additionally, these machines are used in safety critical systems that may demand constant speeds.

For example, conveyors and other appliances that are found in a factory set up, hence, they should be done to allow for torque requirement at a specified speed.

These motors can develop high torques at low speeds hence they are suitable in heavy duty applications where they are supposed to be used continuously.

Such types of motors these motors are useful in dry product manufacturing in the food and pharmaceutical sectors.

DC Permanent Magnet Motors

For instance, in some cases, it is more effective to use a different type of the electric motor with permanent magnets in electric traction, it is called a traction machine.

DC permanent magnet motors run on direct electric current which is simple to use and regulate.

They are essential for applications that need control of variable speed and force, like robotics and electric transportation.

It is not always sufficient to use only electric power in the motors, rather there is a need to regulate the output in terms of the power and the direction changes, this is why the provision for such regulation is made in DC motors.

This is of great significance, as other motors are lagging behind in attaining such tactility, also due to the capacity of the motors to rest on immediate torque during starting it becomes convenient for greater and dynamic application.

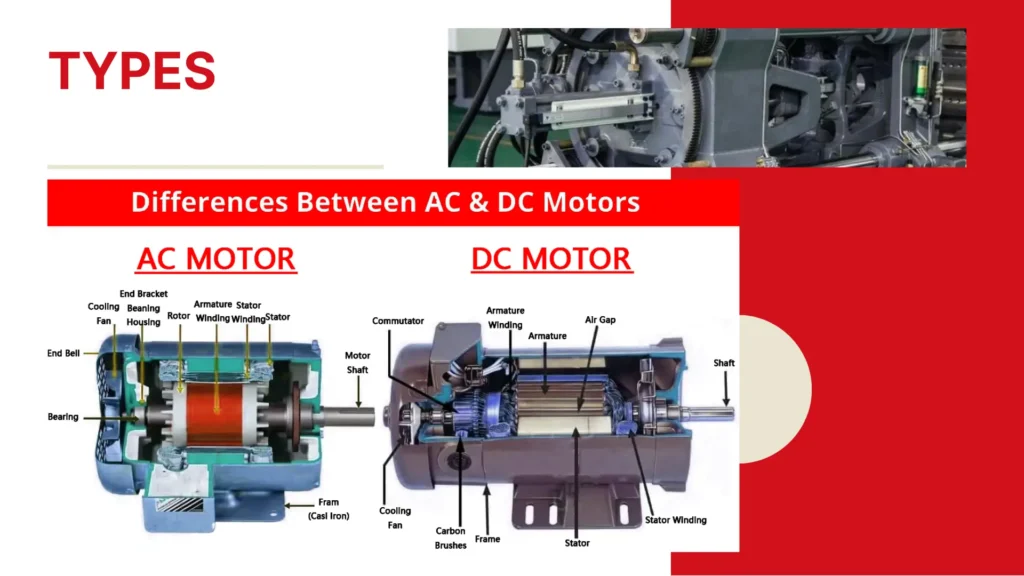

Dissimilarities in AC and DC Motors

The study to familiarize oneself with the different issues involved with the Permanent Magnet motors and also AC and DC motors is very necessary for anybody who would need to purchase these products.

There are, however, some differences that can be observed in the functionality of the two motors.

High-speed applications are generally better understood and implemented using AC motors whereas DC motors are preferred for applications requiring precise control of speed.

Also, AC motors are progressively more sophisticated in terms of control implementation whereas DC motors operate on more regular control systems.

After determining the specifics of the task, the client is able to make selection of the type of motor with the maximum efficiency.

Also read:

Essential Guide to High Efficiency Permanent Magnet Motor Specifications

Applications of Permanent Magnet Motors

Industrial Automation

In terms of industrial automation, PMMs are considered an indispensable component.

Regulators of a number of devices, including robotic manipulators as well as conveyor systems, employed in the manufacturing process, and with countable number of times they are ranked as a delay in a certain process, their application callowsfor very high production levels.

The dependability of PMMs controls better productivity which means minimal waste and adjusted production efficiency is generally high.

The recruitment and retention of the customers of PMMs in all other areas of the industry will be very simple.

Electric Vehicles

Due to efficiency issues, the trends in the LSM sector have drastically changed with the advent of electric vehicles, like Tesla cars. Sieves usually so used have the electric drive whereas radial blower is employed for handling of air in the chamber.

Some motors such as Sudmo motors are at the impression and this electric motors are also likely present in the precision engineering industr.

Mechatronics services etc are installed in dropped ceiling and at the nearby column.

Home Appliances

Over the past decade, the use of permanent magnet motors in the home appliance industry has increased greatly.

They are used in washing machines, dishwashers, refrigerators etc. this type is best suited by the very low level noise and the small enclosures of the appliances.

In terms of design, this method also allows the manufacturer to make products that do not look like over 1000 watt operating products, yet are close to them and have little power losses.

Renewable Energy Systems

The use of PM motors is of high importance in the renewable energy systems so as to ensure the optimal energy process.

For example, in the case of wind turbines; PM motors are employed so that the kinetic energy produced by the wind can be transformed to electrical form appropriately.

With regard to solar energy, PM motors are typically applied in tracking systems in a bid to increase the amount of solar radiation.

Their effectiveness enables the reduction of comprehensive expenses of renewable energy systems without compromising their economic viability and environmental compatibility.

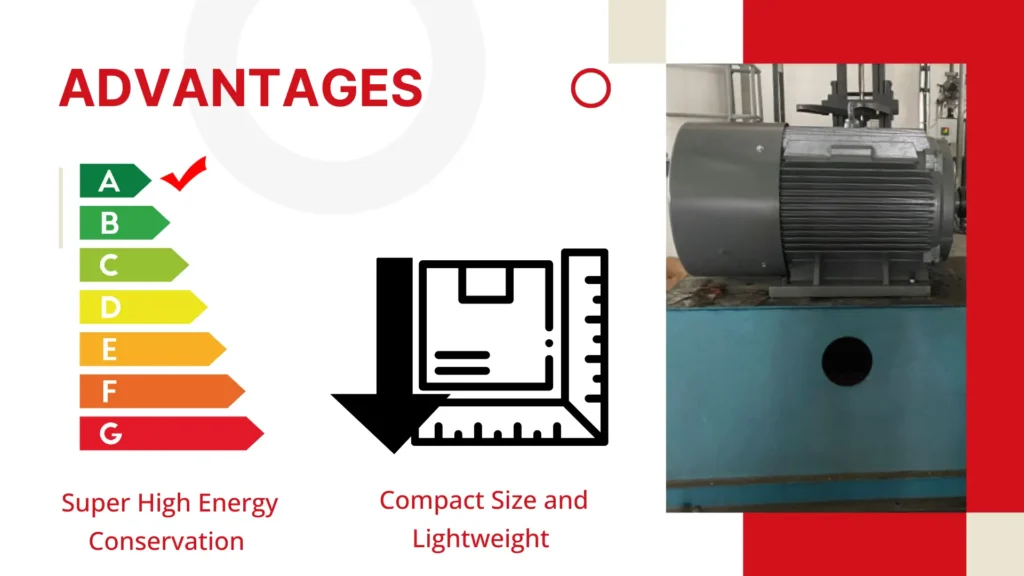

Advantages of Permanent Magnet Motors

Super High Energy Conservation

PMMs posses several benefits but the base of them all is their extre,ely high energy efficiency, with some PMMs being able to rexceed 90% efficiency.

This reduced energy consumption will lead to less waste of resources and decreased cost of operations.

This is the reason why — as historically PMMs use fewer resources than many other electrification materials and technologies — it has took decades before decisions have began to be made in favor of PMMs, practical and economical.

Lastly, the expressed advantage allows air’s sustainability requirements to be addressed in addition; energy efficiency and conservation goes green.

Compact Size and Lightweight

PMMs possess a range of application friendly features such as small size and lightweight.

This makes them extremely popular in such industries where the actual working space is limited only forczxamplet some of aircraft and automotive sectors.

Due to the fact that the size of the motor can be reduced without changing its physical footprint, motor shafts are designed to carry more and as a result reduces the motor settling distance.

Finally, since PMMs are very light; they are also portable and can be as a part of portable apparatus or equipment.

Installation Time

Conversely, deliberate inclusion of PMMs in anything significantly lower the total cost of maintenance.

As a single unit i.e. with lesser number of parts and components, this type of motors is less exposed to risk factors.

This reliability reduces the interruptions caused by the necessity to repair the equipment in a fault condition and idle time which brings about extra cost to the organization.

Reducing maintenance costs also allows the enterprise to invest the saved resources more effectively, especially where maintenance is expensive and tedious work.

Furthermore, such materials usually have lower levels of maintenance, leading to extending the life of the equipment hence more returns.

Dynamic Voltage Control

Several characteristics of the motor lead morphed their use abilities to high torque; very fast response, etc.

These, so called pass, features are very important for the state-of-the-art applications like robotics and automation.

Any dynamic system or machine that enables one to adjust the control to move guidance, control torques torque ripple or animation may have those features, which may be either magnetic or mechanical enabling the torque capability to be safely changed to a negative value in case of an overload.

Challenges to Consider

Higher Initial Costs

It goes without saying that the cost of perma¬nent magnet materials affects the formal cost of PMMs allowing for less adaptation for those less expensive materials applied in the making of the traditional motors.

This will attract more investment in so many kind of businesses than in smaller organizations who cannot afford such an investment especially at the beginning.

Nonetheless, before building to that cost, one has to consider the service energy and more so maintenance which cost is typically more than the above cost.

Customers need to assess what in particular they are looking for, the reasons for it and potential projected more than normal margins which could be earned through the use of PMMs.

Temperature Sensitivity

Unlike isolated coils or coils that incorporate iron cores, permanent magnets are very sensitive to temperature.

Variations in the temperature as such would affect their operational efficiency. In addition, high temperature might reduce the attraction of the magnets that can result in a drop of performance of the machine and ruin its operability.

According issues figure its important to select the PMM taking into account where it will be used.

Adequately handling the heat and using the correct motor design in terms of specifications will reduce the risk.

Supply Chain Concerns

Production of permanent magnets for use in machines, most of the time neodymium horium tetroxide magnets, is made from rare earth elements which can present a challenge of their availability across the supply chain.

Since these components have a significant distribution and price inflations are predictable, this contributes to the factors affecting supply and demand.

The businesses need to properly vet their suppliers and try to limit potential supply or delivery related issues by looking at other materials or production methods.

Organizations need to know the challenges which the industries they are in face so that they can effectively respond to them.

Conclusion

At the start of the motor innovation, both Permanent magnet motors have been a substantial development.

And these motors have some advantages like being very efficient with a good speed control ability, simplicity and ease of jobs of measurements, better safety than other available motors and also the maintenance level is relatively smaller.

When it comes to the functions of the above motors, manual analysis of the strengths of both motors is required and decisions will be informed.

Fundamentally however, the changing of the rules of the current technology allows machines such as Permanent Magnet Motors to issues in different areas of industry that were previously impossible.

Conclusively, it is encouraged that supporters of PMMs come out and let their true innovations work towards changing previous methods even when it seems risky to do so.