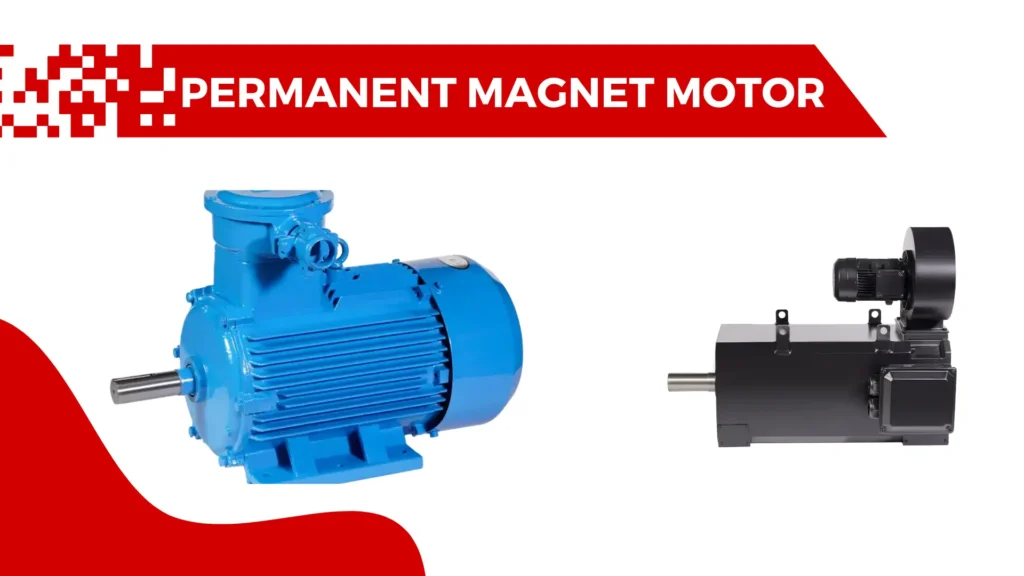

Permanent magnet motors have found application and acceptance in industries today due to their performances, energy consumption, and eventual lower cost of maintenance.

Permanent magnet motors are increasingly being adopted into industries due to the increasing demand for energy efficiency and a greener environment.

In areas where conserving energy is being sought after, like electric vehicles and renewable energy systems, permanent magnet motors are becoming the trend.

Their design allows them to generate more torque in a smaller and lighter package, now highly demanded in major industries such as aerospace and robotics.

With a strong global focus on sustainability and reduction of carbon footprint, the relevance of PMMs assumes even greater dimensions.

Learn More:

- Top 10 Permanent Magnet Synchronous Motor Manufacturers in China

- Steps for Permanent Magnet Synchronous Motors

- How to Choose a Permanent Magnet Synchronous Motor

Why Permanent Magnet Motors Stand Out

The permanent magnets ascertain that less electrical energy is utilized in generating the magnetic field, hence economizing a great deal of energy. This applies to industries where the motors are running for extended periods of time, thus allowing huge savings in the building up of energy.

Hence, one of the primary benefits of PMMs lies in their energy efficiency, meaning that the corresponding reduction directly translates into decreased electricity costs.

Thus, when companies want to minimize their operational cost, PMMs represent a great potential solution.

Another differentiating aspect of PMMs is how their maintenance is minimal compared to the competition.

Most conventional motors, with their brushes or other wear-and-tear components, require constant tuning in order to keep them at an optimal level of operation.

The PMM reduces overall business downtime and maintenance expenses due to fewer moving parts and nothing particularly prone to deterioration.

Key Benefits of Permanent Magnet Motors

There are several advantages of permanent magnet motors that make them very suitable in a variety of applications.

Some of the most crucial advantages are high torque density, compact size, and lightweight.

High Torque Density

The permanent magnet motors generate higher torque for the same physical size as compared to conventional motors.

This enables an enterprise to be supplied with smaller motors without necessarily compromising the power output.

This advantage has become crucial in industries like automotive and robotics where available space is a limiting factor.

Compact Size and Lightweight

PMMs are lighter and more compact compared to traditional motors; thus, they are ideal for applications where weight and size are an issue.

Whichever it might be-in electric vehicles, to support improved range through a reduction in weight, or in robotics, where compact design improves maneuverability, PMMs stand out as the preferred choice.

Improved Performance Across Diverse Environments

Permanent magnet motors have traditionally enjoyed a reputation for reliability and performance in harsh conditions, including high temperatures, humidity, and dust.

PMMs are capable of operating efficiently even in industries with extreme conditions. They entail lower operational costs in the long run.

Lower Operational Costs Over Time

With high efficiency and low maintenance needs combined, PMMs could offer enormous savings in operational costs over their lifetime.

While the upfront investment is higher, long-term savings make them cost-effective for businesses.

Product Recommend:

- Three-phase Permanent Magnet Synchronous Motor

- Three-phase Explosion-proof Permanent Magnet Synchronous Motor

- Three-phase Rare Earth permanent magnet synchronous Motor

Industries Benefiting from Permanent Magnet Motors

Permanent magnet motors are going to reinvent many industries due to their efficiency, compactness, and sturdy performance.

Three important sectors where the impact of PMMs is certain to be felt are listed below:

Automotive Industry and Electric Vehicles

Their high efficiency and compact size are remarkably suitable for electric vehicles since light-weight and powerful motors will extend driving capability and improve overall performance.

The leading automobile makers are incorporating PMMs into their electric drive trains to enhance efficiency and reduce the vehicle’s footprint of emission.

Renewable Energy

In the field of renewable energy, however, the role of PMMs becomes very crucial.

PMMs have application in wind turbines and a number of other green energy technologies.

Equipped with PMM technology, wind turbines manage to convert wind energy into electricity much more efficiently, thus maximizing the energy output and consequently reducing the mechanical losses.

As the world is starting to look for and utilize much ‘greener’ sources of energy, PMMs contribute by taking steps toward that direction.

Aerospace and Robotics

Permanent magnet motors have become a favorite in aerospace industries where accuracy and reliability matter most due to their light weight and high performance.

In robotics, PMMs allow for more agile, powerful, and energy-efficient robots. The application of permanent magnet motors in space and robotics points out that such motors are indeed applied in varied state-of-the-art technology fields.

Top Considerations When Purchasing a Permanent Magnet Motor

Power and Torque Requirements

First, there is the issue of the power and torque output of the motor.

The load requirements of the intended application have to fall within the operational limits of the motor.

Whether it is heavy machinery or a light robotic arm, the motor needs to be able to provide enough torque for the operation without straining.

Operational Environment and Temperature

The operational environment differs a lot, and thus the right choice is made.

If the temperature, humidity, or corrosive elements are to happen directly with the motor, make sure it’s designed to survive in such conditions.

Various PMMs are designed for worst operational conditions and offer superior robustness.

Cost Efficiency and Return on Investment

While permanent magnet motors are often higher in cost at the outset, their efficiency and long service life, combined with reduced maintenance, can offset costs with considerable savings.

The accurate calculation of ROI should consider energy saving, maintenance cost reduction, and longer service life of the motor.

USA’s Leading Manufacturers of Permanent Magnet Motors

Nidec Motors

Headquartered in St Louis, Missouri, Nidec Motors is one of the oldest serving global corporations in the field of motor technology.

Its product range comprises permanent magnet motors available within a broad portfolio. Its products find their applications in many industries, including industrial, automotive, and HVAC applications.

Allied Motion Technologies

Its headquarters is located in Buffalo, New York. Having a primary focus on motion control products, the company, Allied Motion Technologies, produces some of the most efficient permanent magnet motors used for commercial and defense applications.

ElectroCraft, Inc.

ElectroCraft engineers high-performance motors headquartered in New Hampshire for industries ranging from robotics and medical devices to industrial automation.

Johnson Electric

With headquarters based in Ohio, this is a prominent manufacturer of fractional horsepower and permanent magnet motors for automotive and industrial use.

MET Motors

METER Motor was established in Minnesota to be a trustworthy brand in the field of custom-designed permanent magnet DC motors, together with specific solutions for various industries.

Shaoxing Jiayu Import and Export Co. Ltd.

The experienced design team adopts extensive knowledge of the industry to come out with creative and state-of-the-art solutions to meet the specific needs of our clients.

All products come in good quality and are CE certified, hence offering high reliability and performance in various conditions of operation.

Dietz Electric Co., Inc.

It is based in Wisconsin and deals with electric motors such as permanent magnet motors, among others.

Dietz Electric provides several services regarding customization to meet the requirements for particular clients.

AutomationDirect

Headquartered in Georgia, this company distributes a wide variety of motors.

AutomationDirect has quite efficient and very reliable permanent magnet motors suitable for industrial and commercial applications.

Hitachi

Although it originated in Japan, Hitachi has excellent ground in the United

States with its permanent magnet motors, which are widely used by industries and energy systems.

Composite Motors, Inc.

This is a company based in Florida, specializing in their fractional horsepower motors known for durability and including permanent magnet kinds to be used in demanding applications.

Technological Innovations in Permanent Magnet Motors

Permanent magnet motors are incessantly enhanced by a number of technological innovations that enable the motors to be further efficient and versatile.

Some of these are listed below:

Materials and Magnet Technology Development

Newer materials with stronger and lighter rare-earth magnets can enable engineers in the design and development of high-performance motors without adding any size and weight, thereby helping improve the overall performance of PMMs for a wide range of applications.

New Design Techniques for Higher Efficiency

Different new design techniques are being developed to further enhance the efficiency of permanent magnet motors.

These techniques, such as optimization of rotor and stator configurations, reduce losses and improve torque, making PMMs more attractive for industries that focus on energy savings.

Integration of PMMs with Digital Control Systems

Integration of PMMs with Digital Control Systems This is where digital control systems have been integrated to give precise motor control and monitoring.

This means improved energy management as well as efficiency and the opportunity for remote diagnostics of problems, making PMMs a smart choice for modern industrial systems.

Sustainability and Environmental Impact

Permanent magnet motors have found their role in promoting sustainability and reducing the environmental footprint of industrial operations:

How Permanent Magnet Motors Contribute to Energy Savings

PMMs are very efficient in that they consume less electricity for the same amount of work done compared to traditional motors.

This constitutes great energy savings, especially where motors run continuously.

Carbon Footprint Reduction in Industries

The permanent magnet motors help companies reduce carbon emissions by reducing energy consumption.

This is increasingly important in industries looking to make their operations greener and meet environmental regulations.

Enabling the Transition to Green Energy

Application of PMMs in wind and, more recently, solar power systems has brought these motors into a very important role within renewable energy.

Therefore, their efficiency and reliability make them indispensable factors in the transition to cleaner energy sources and contribute to a reduction in reliance on fossil fuels.

Challenges Facing Permanent Magnet Motors

The path ahead for permanent magnet motors is fraught with challenges that might influence adoption in the following ways:

Cost of Raw Materials Like Rare Earth Element

But permanent magnets in PMMs are very often made of rare earth materials.

And the prices for these materials continue to fluctuate, making the production cost of PMMs quite high.

This is why, for some companies, such machines may not be that affordable.

Supply Chain Challenges

The rare earth supply chain is highly susceptible to geopolitical tensions and market instability.

This may cause shortages or delayed availability of those materials, which are then translated into PPM production.

Competition from Other Motor Technologies

While PMMs have many advantages, other motor technologies, including induction motors and switched reluctance motors, are also advancing.

In some applications, these other technologies may pose a challenge, especially in applications for which cost is the major driving factor.

Conclusion

In view of the fact that energetics and sustainability are key issues in most industries, the demand will continue to increase for permanent magnet motors.

The technologies and material used continue to develop, making these PMMs more powerful and efficient while also adapting to a greater number of applications. Their growing applications in industries such as automotive, renewable energy, and aerospace indicate a bright future for this technology.

Now, this is a very good opportunity for businesses to step up with investment in permanent magnet motors and invest in saving energy, enhancing performance, and keeping ahead in a market that gets more competitive with its environmental concerns.