Germany enjoys an esteemed global reputation in excellence in engineering and innovative technologies, especially where electric motors are concerned.

Permanent magnet motors have recently gained high application rates due to efficiency, reliability, and compactness.

It is at this point that it becomes very necessary to understand the landscape of PMM manufacturers as different industries work toward energy efficiency and operational performance.

Be it manufacturing, automotive, or renewable energy, having this key knowledge will help you move in the right direction in finding an appropriate motor that caters to your needs.

Learn More:

Top 10 Permanent Magnet Motor Manufacturers in China

Why Permanent Magnet Motors Stand Out

Energy Efficiency

The PMMs have been developed to convert electrical energy into mechanical energy with a minimum of losses, resulting in huge savings in energy.

This efficiency becomes particularly valuable in an industrial environment where energy costs are a huge portion of operational costs.

Companies lower their electricity bills by using PMMs, which can help improve the bottom line while contributing toward sustainability objectives.

Compact Design

Since permanent magnets are used, the motors are relatively smaller in size and lighter than their traditional counterparts.

This compactness makes it easily integrable with different applications, ranging from industrial machines to electric vehicles.

For places with minimal space-for example, areas like factories or cities-the lesser space occupied by PMMs becomes an asset.

High Performance

The PMM works excellently within a high torque range at low speeds, hence being ideal for applications that require high precision in control.

This aspect is important in industries involving robotics and automation because there is a high need for consistency in output.

This also ensures that PMMs are able to handle specific tasking with efficiency since their torque remains constant in most operating conditions.

Product Recommend:

- Three-phase Permanent Magnet Synchronous Motor

- Three-phase Explosion-proof Permanent Magnet Synchronous Motor

- Three-phase Rare Earth permanent magnet synchronous Motor

Key Benefits of Permanent Magnet Motors

Less Maintenance Costs

Perhaps one of the most attractive features of PMMs is that they require less maintenance compared to the others.

With fewer moving parts and no brushes to wear out, these generally require less maintenance than the other conventional motors.

This lesser maintenance translates into less downtime, and hence businesses can be more productive instead of constantly undertaking repair work.

Savings from reduced maintenance costs more often than not accumulate over time.

Consistent Output

PMMs are also reliable and give consistent performance under variable loads and speed.

This reliability is critical for companies since their operation cannot afford to get interrupted.

In manufacturing where losing a minute will cost them much, the dependability of PMMs facilitates smooth and efficient production.

Compatibility with the Environment

Lower carbon emissions on account of energy efficiency of PMMs accord with global sustainability goals on sustainable development.

Hence, the adoption of PMMs can be a strategic decision as more firms are trying to improve their environmental credentials.

With reduced carbon footprint, businesses not only meet regulatory requirements but also attract eco-conscious consumers.

Longer Operational Life

Due to their structure and design for efficiency, PMMs often have longer operational life compared to the traditional motors.

This could further reduce business costs because the frequency in replacement is low.

Hence, investing in a PMM is usually a long-term strategy in keeping operations efficient while reducing capital expenditure.

Industries Benefiting from Permanent Magnet Motors

Automotive

The automotive sector, on the other hand, has taken a keen interest in the application of PMMs toward electric vehicle and hybrid applications.

As we move into the green transportation era, so will the application of PMMs, really needed for better performance and lengthier ranges in electric vehicles.

Their compactness and effectiveness further make them ideal to meet the callings of modern automotive design.

Renewable Energy

PMMs will further be indispensable in renewable energy applications, like wind turbines and solar energy systems.

The efficiency with which they convert energy from such renewable sources into useful power becomes important for the furtherance of clean energy technologies.

By integrating PMMs, companies are able to increase overall energy conversion, hence contributing to a greener future.

Aerospace

Some of the beneficial characteristics of PMMs include lightweight and high efficiency, which make them handy for use in the aerospace industry.

These motors are much needed in aircraft since performance and fuel efficiency depend highly on every ounce of weight on an airplane.

In the aerospace sector, wherein continuous innovative ways to minimize its impact on the environment are found, PMMs are now gaining much importance.

Top Considerations When Purchasing a Permanent Magnet Motor

Application Requirements

Before purchasing a PMM, the exact requirement of the application should be defined.

Some of the major factors for which the whole motor design has to be considered include torque, speed, and environmental conditions.

Once these parameters are well known, you would be able to select a motor optimized for that particular application, thereby enhancing overall performance and effectiveness in operations.

Cost vs. Value

In the assessment of PMMs, one has to be in a position to estimate the fronting investment in respect of possible long-term savings from energy and maintenance.

Whereas PMMs are more expensive at the initial purchase than these other motors, their efficiencies in operation translate into massive savings over time.

A full cost-benefit test can identify best value for your business, ensuring that a potential investment will pay off in the long term.

Manufacturer Reputation

The track record of the manufacturers is quite crucial in the selection of a PMM.

Look at factors such as reliability, customer support, and quality of product.

A good manufacturer gives you a guarantee of a quality product backed by reliable service.

Thus, reviews, testimonials, and industry recognition will go a long way in helping you make your choice.

Germany’s Leading Manufacturers of Permanent Magnet Motors

Siemens AG

Siemans AG is a leading electrical engineering company in the global marketplace. Its product includes a range of PMMs with acknowledged reliability and efficiency.

Siemens has been well known in many industrial fields for decades and therefore is a very good partner when it comes to company business with a broad portfolio of motors.

With continuous innovation at the core, it stays updated with the latest developments in motor technologies.

Bosch Rexroth

The Bosch Rexroth Company majors in drive and control technologies.

It manufactures high-performance PMMs that target automation industries, among other manufacturing companies.

Its motors have been designed with the latest application requirements for efficiency and dependability. Its high repute makes them preferred by many companies.

Weg Motors

The leadership taken by Weg in innovative electric motor solutions – such as PMMs – stands to prove that full energy efficiency is quite achievable under the most varied applications.

The commitment to quality and technological development has made it one of the leaders in the motor manufacturing industry with a production that goes from industrial to commercial markets.

Danfoss

Danfoss designs advanced PMMs for renewable energy and industrial automation with sustainability and energy efficiency in mind.

Their products are built for maximum efficiency with minimal impact on the environment and hence are a great choice for companies considering environmental concerns.

Maxon Motor

Maxon specializes in precision motors, including PMMs for robotics and automation.

These products realize high torque in compact designs, thus enabling applications where space is restricted.

Maxon’s commitment to quality and precision ensures that the motors meet even the staunch demands of high-tech industries.

Schneider Electric

Schneider Electric will provide the industrial and commercial segments with efficient motor solutions based on its product portfolios on PMMs.

Its innovations and product offering relating to sustainability make it an integral player within the motor manufacturing industry as it helps businesses optimize their energy use and boost operational efficiency.

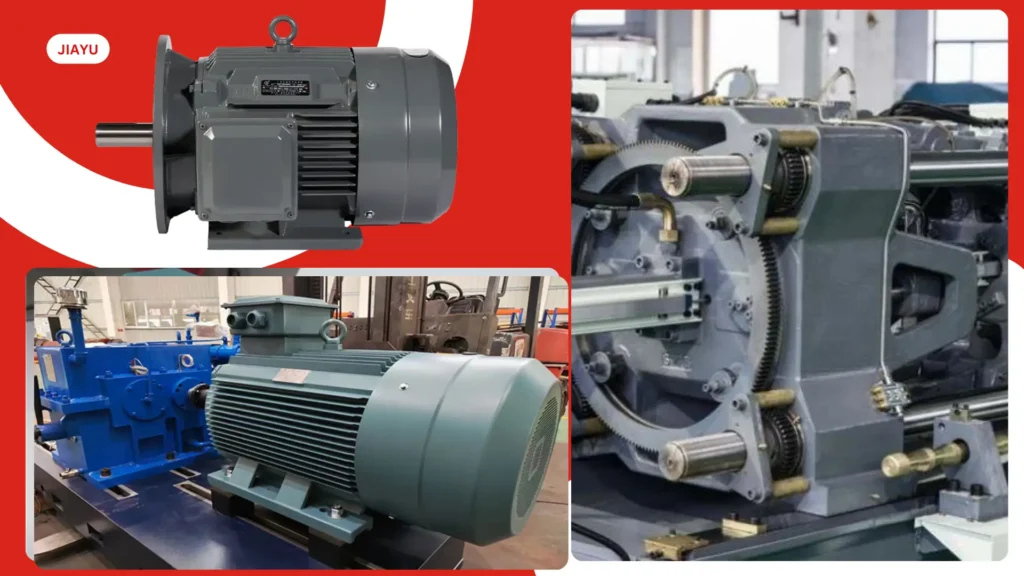

Jiayu Import and Export Co. Ltd.

Supported by an experienced designing team with deep industry knowledge to create innovative and updated solutions according to customers’ needs, Jiayu Import and Export Co., Ltd. focuses its business on a vast range of products of high-quality standards and with CE certification to guarantee reliability and performance in diverging conditions.

Nidec

Nidec produces small to medium-sized PMMs and also offers practical solutions for home appliances, automotive industries, among others. Innovation and quality are the main focus of this company, and it is known as a reliable manufacturing company that provides motors for every need a customer may have.

Baldor Electric Company

ABB owns a subsidiary called Baldor Electric Company, which produces high-efficiency PMMs targeted for industrial use.

Their motors are designed with reliability, performance, and readiness to go – even in demanding tasks.

Having served in a long-standing career in the production of motors, it has earned its reputation among customers as a brand one can rely on.

Emerson Electric

Emerson delivers a broad portfolio of PMMs, with a focus on energy efficiency and innovative solutions for industrial and commercial applications.

Their commitment to quality and customer satisfaction ensures that the motors provided to clients meet but actually exceed their expectations.

Technological Innovations in Permanent Magnet Motors

Advanced Magnet Materials

New magnet materials currently under development are improving the performance and efficiency of PMMs.

The innovations in material sciences create more powerful and lighter motors, which enable better energy conversion and smaller motor sizes.

These allow manufacturers to build highly efficient motors that meet the very demanding requirements of modern applications.

Smart Motor Technology

Integration of IoT technology into PMMs offers the ability to monitor in real-time and perform predictive maintenance, thus enabling the enterprise to optimize motor performance and reduce overall downtime.

Smart motors can let the management system know about their performance metrics in order to maintain proactively or quickly respond to potential issues.

Enhanced Cooling Systems

Newer cooling methodologies are in development as a method of elongating the useful life and efficiency of the PMMs.

Effective cooling solutions help maintain optimum operating temperatures, reducing wear that allows very reliable performances over time.

This is all the more so in high-demand applications where overheating can lead to failures.

Modular Designs

Many manufacturers are now providing modular designs for PMMs, and for that reason, customization is easily made possible and has opened a broad avenue in applications.

Modular motors could be designed to meet specific needs that enhance performance.

Likewise, maintenance and upgrade become much easier since individual components would be easily replaced or modified without having to replace the entire motor.

Sustainability and Environmental Impact

Energy Efficiency

They also use less energy when compared to the conventional ones, ultimately raising less demand on energy and thus reducing the levels of carbon emissions.

This efficiency supports global sustainability efforts and helps businesses meet their corporate social responsibility goals.

This would greatly reduce a company’s ecological footprint with the use of PMMs.

Renewable Energy End

Permanent magnet motors assist in renewable energy applications for the optimization of energy conversion from both wind and solar, further encouraging cleaner technologies.

Businesses are able to boost efficiency in general by adding permanent magnet motors to these systems and create a more sustainable future regarding energy use.

Challenges Facing Permanent Magnet Motors

Material Costs

The cost of the rare earth material used in these PMMs differs and hence impacts the overall production cost and prices to the consumers.

These fluctuating costs make the budgeting for companies that intend to invest in a PMM complex.

Supply Chain Vulnerabilities

PMMs rely on special materials for their production; consequently, there is the possibility of a disruption in the supply chain because of such dependence.

To curb this issue, manufacturers have to strike a balance in the regular delivery of components, which influences the production schedule and product availability.

Complexity of Manufacturing Processes

PMM manufacturing is a highly technological process, and this will demand specialized experience and knowledge.

For example, the manufacturers are obligated to ensure quality production through direct investment in training and development.

All these factors ensure that other firms cannot enter the market easily.

Conclusion

Permanent magnet motors are a good investment in various fields in Germany because of efficiency, reliability, and long-lasting performance.

An informed decision that comes in terms of performance by a company based on the understanding of advantages and disadvantages of permanent magnet motors is through making an evaluation of reputable manufacturers.

Companies shall remain focused on future trends related to technology and the industry in order to maximize the full potential of PMMs in the shifting market.

With innovation and sustainability at the forefront of industries, PMMs will always stand in the spotlight for efficiency and performance improvements across industries.