Over these years, France has been the focal point of engineering and innovation.

It is a significant place when it comes to electrical machinery, and lately, permanent magnet motors have gained much importance due to their efficiency and versatility, finding their applications spanning from household appliances and HVAC systems to electric vehicles.

The paper shall look into the top manufacturers of permanent magnet motors in France, along with their contributions and other aspects that give them an edge.

Be it manufacturing, renewable energy, or automotive; knowing who these key players are will help you make better buying decisions.

Learn More:

- Top 10 Permanent Magnet Motor Manufacturers in Ethiopia

- Top 10 Permanent Magnet Motor Manufacturers in Sri Lanka

- Top 10 Permanent Magnet Motor Manufacturers in Singapore

Why Permanent Magnet Motors Stand Out

Permanent magnet motors boast certain advantages that give them a unique status apart from other conventional motor technologies. Some of the advantages are:

Energy Efficiency

PMMs are also designed to ensure that electrical energy is transformed into mechanical energy with minimal losses, making them highly efficient.

Efficiency is crucial in every business, as it reduces energy consumption and operational costs, especially in areas where applications might need a lot of energy.

Compact Size

With permanent magnets, the machines can be smaller and lighter for their given rating compared to conventional motors.

This compactness makes them easily integrate with larger applications, such as industrial machinery or electric vehicles, where space is always an important factor.

High Torque at Low Speeds

Among the major characteristics of PMMs is the excellent torque performance they provide, even at low speeds, which essentially plays a major part in applications where precision control is necessary.

This suitably makes them very efficient in robotics and automation, where high consistency and reliability are assured.

Key Benefits of Permanent Magnet Motors

Less Maintenance Costs

PMMs require less maintenance compared to conventional motors due to fewer moving parts and no brushes that will eventually wear out.

These mean lower operational costs and reduced downtimes, which enable business concerns to attend more to productivity.

Consistent Performance

PMMs are characterized by delivering steady and predictable performance over a wide range of loads and speeds, hence their great reliability for industrial applications where operation is often in continuous mode.

The manufacturer is certain that PMMs can increase their output without constant breakdowns.

Environmentally Friendly

The efficiency of PMMs towards energy consumption equals reduced carbon emissions, hence falls in line with international drives towards sustainability.

Companies using PMMs are sure of improving their ecological ratings and meeting an increasing number of regulatory requirements for cleaner technologies.

Product Recommend:

- Three-phase Permanent Magnet Synchronous Motor

- Three-phase Explosion-proof Permanent Magnet Synchronous Motor

- Three-phase Rare Earth permanent magnet synchronous Motor

Industries Benefiting from Permanent Magnet Motors

Automotive

In particular, the automotive industry relies increasingly on the usage of PMMs in electric vehicles and hybrid systems.

This is very important for future transportation, given that their efficiency and compact design are critical in leveraging better performance and driving ranges for electric vehicles.

Manufacturing

PMMs apply to a wide range of manufacturing industries, particularly in automation and robotics.

Their traits of precise control and reliability make a big contribution to production efficiency by improving throughput and reducing operational costs for manufacturers.

Renewable Energy

PMMs are finding many useful applications in the renewable energy sector, such as wind turbines and solar energy systems.

Since these can further optimize energy conversion, they have emerged as an integral part of sustainable energy solutions to support greener technologies.

Aerospace

In the aerospace world, lightweight and high-efficiency features make the PMM a very valuable motor.

These motors contribute greatly to improving aircraft fuel efficiency and performance, thus adding to the sustainability of flying.

Top Considerations When Purchasing a Permanent Magnet Motor

Application Requirements

Define very clearly what your application requires in the form of torque, speed, and environment.

By knowing these factors, you will be able to choose a motor that will serve your needs appropriately.

Cost vs. Value

Keep in mind the upfront cost in relation to long-term savings in energy and maintenance.

While PMMs are more expensive during the initial purchase stage, their efficiency guarantees significant savings over the long term, thus making them quite valuable investments.

Manufacturer Reputation

Research the manufacturers you are considering.

Read reviews, request customer testimonials, and inquire about industry recognition to make sure you select a reliable partner who will deliver quality products.

Customization Options

See if the manufacturer has customizable solutions for your needs.

Such a customization helps improve the performance of having a motor that fits your application perfectly for superior results.

France’s Leading Manufacturers of Permanent Magnet Motors

Schneider Electric

A motor from Schneider Electric can be designed to optimize energy consumption and should, therefore, be the perfect solution for any industry wanting to reduce operational expenses while increasing productivity.

It has a wide portfolio that ranges from industrial automation, renewable energy systems, and commercial buildings up to a specific solution that will fully meet the customer’s requirements.

Valeo

At Valeo, the attention is on top-of-the-range automobile technology, especially making PMMs for electric and hybrid vehicles.

Innovation and care for the environment are what drive Valeo right at the heart of the automobile world and thus take part in greener mobility.

Their PMMs are designed to deliver high efficiency and performance for better vehicle range and reduced emissions.

SAFT

The motors of SAFT came equipped with a high sense of commitment toward efficiency and durability so they could bear such heavy use in industry with a guarantee of maximum performance.

For the same reason, the company is incessantly innovative, and the PMMs are packed with state-of-the-art technologies, making them an instant favorite among businesses seeking enhanced operational efficiency.

Moteurs Leroy-Somer

Moteurs Leroy-Somer is a prominent electric motor manufacturer with a wide portfolio in drive systems offering a wide range of PMMs.

The company generally uses its motors in a number of industrial automation applications due to their sturdy design and efficiency.

Moteurs Leroy-Somer is committed to delivering quality products that answer diversified needs.

Elmo Motion Control

Elmo Motion Control is a leading company in precision motor control solutions. It provides a line of PMMs built to perform in demanding conditions in robotics and automation.

Their products are engineered to provide unparalleled accuracy and responsiveness, becoming the ideal choice for complicated systems involving motion control.

The commitment towards innovation means that motors at Elmo come equipped with advanced technologies for users’ benefits in productivity and efficiency.

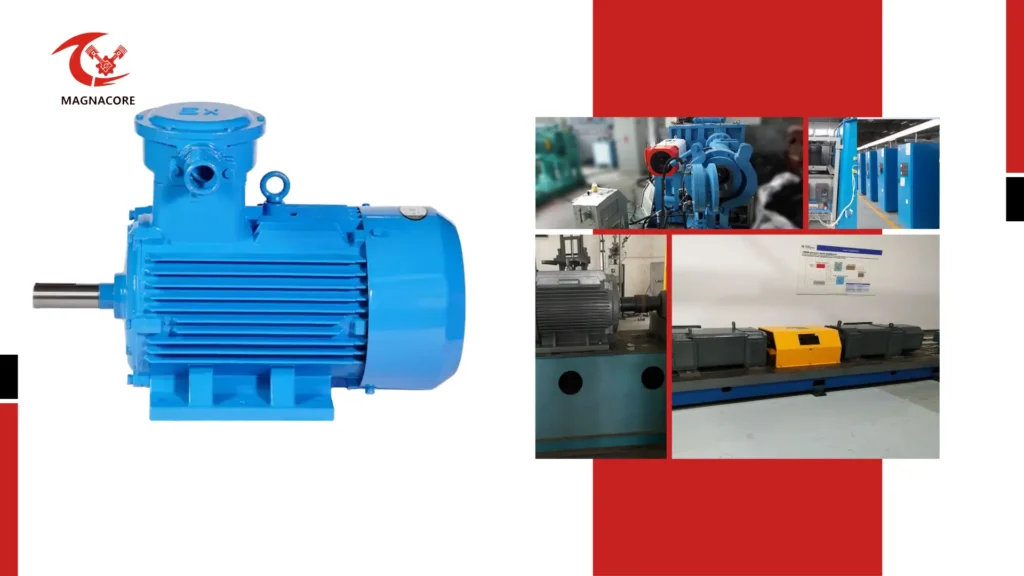

Jiayu Import and Export Co. Ltd.

Jiayu Import and Export Co. Ltd. is known for an innovative approach toward creating high-tech solutions by catering to diversified needs of clients.

By applying extensive industrial experience, a professional designers’ team creates PMMs that can operate securely across a wide operational environment.

The products are manufactured under strict quality assurance processes and all fully CE certified to meet the highest international standards.

With a commitment to excellence and customer satisfaction, Jiayu is very well-placed as a reliable partner for enterprises looking for advanced motor solutions.

Baldor Electric

Since its inception, Baldor Electric has been the subsidiary of ABB. It is one of the well-known companies offering high-efficiency PMMs to industrial applications.

The company pays great attention to reliability and performance, which increased the demand for its motors from leading manufacturers across various industries.

The PMMs by Baldor are designed to meet demanding applications while maintaining consistency in output with energy savings.

Legrand

Legrand is one of the leaders in electrical and digital building infrastructures, and it offers PMMs for applications related to both commercial and residential settings, all of which help ensure energy efficiency.

Its focus on innovation and sustainability pushes the company to develop motors that work towards better energy management and reducing environmental impacts.

Legrand’s PMMs are designed for effortless integration into building systems to ensure reliable performances that add to the overall energy efficiency.

Sodecia

Sodecia provides automotive systems with innovative PMMs for electric vehicle applications and other automotive uses.

Very focused on technological improvements, Sodecia’s motors currently answer the new requirements of the automotive business.

The Company’s commitment to sustainable results with performance makes it a key supplier for manufacturers looking to improve the efficiency and reliability of their vehicles.

Fischer Elektronik

Fischer Elektronik fabricates a wide range of electronic components.

Their PMMs are renowned for accuracy and performance in industrial applications.

The company strives to always offer quality products meeting today’s high demands.

It is with regard to this that Fischer Elektronik designed its PMMs to be versatile and reliable, finding their application in a wide range of fields including automation and robotics.

Technological Innovations in Permanent Magnet Motors

Advanced Materials

Improvements in magnet material further enhance the efficiency and performance of permanent magnet motors.

New materials allow for higher power density and improved thermal management, therefore giving rise to better motors.

Integration of Smart Technologies

The integration of IoT and smart technologies enables the PMMs to offer real-time monitoring along with predictive maintenance.

It adds value in the management of operational costs on the back of substantial performance improvements because of the optimization of business operations.

Advanced Cooling Methods

Newer cooling methods are being designed to maintain the operating temperature of PMMs within optimum levels.

The reliability of motors, along with improved life, is dependent on better cooling methods.

This is specifically critical for applications whose demands are showing an upward trend.

Modular Designs

There is also a trend towards modular designs that can easily be engineered to provide customized solutions for specific customers’ needs.

The use of modular motors further simplifies maintenance and upgrades, hence being more adaptable for various uses.

Sustainability and Environmental Impact

Energy Efficiency

PMMs contribute to lower energy consumption and reduced carbon emissions, hence in line with global sustainability goals.

Companies using these kinds of motors, therefore, have a better environmental credential and are able to comply with regulatory requirements.

Recyclability

The material used in PMMs is recyclable, thus encouraging a circular economy and minimizing waste in production.

This aspect of recyclability aids in sustainable practices through resource conservation.

Support for Renewable Energy

It is part of the renewable energy solution such as wind and solar.

They are efficient in energy conversion, hence the transition to clean energy technologies for their reliability and feasibility towards a sustainable future.

Challenges Facing Permanent Magnet Motors

Material Cost Fluctuations

Prices of rare earth materials fluctuate; this increases manufacturing costs as PMMs depend on them.

This may pose a challenge in terms of budgeting by a business that hopes to invest in a PMM.

Supply Chain Dependencies

Dependence on specific material in the value chain poses risks that may cause delays in production.

These risks, which the manufacturers need to hedge, cannot allow the operations to be continuous in nature.

Complex Manufacturing Processes

The technologies utilized in the production of PMMs are of a complicated nature.

In order to achieve quality standards of production, companies have to invest considerably in training and development.

Market Competition

Increasing competition in the motor manufacturing industry could strain the prices, hence reducing profitability and innovation.

The manufacturer would have to continue with heavy research and development functions in order to remain competitive and ensure that customers’ needs are diversified.

Conclusion

Permanent magnet motors are one of the great steps ahead in the field of motor technology; hence, efficiency, reliability, and long life in different industry applications in France.

Understanding the benefits and challenges of PMMs and the leading manufacturers, companies can make proper decisions that better their operational performance.

With innovation in technology and sustainability moving at fast-moving paces, so too will enterprise companies that want to make full use of the potentials of PMMs.

In the future, working industries will be further developed with these advanced motors; PMMs will have an even more critical role in developing efficiency and performance for years to come.