In various industrial and commercial applications, equipment often has to operate in harsh environments, where extreme temperatures, high humidity, dust, and corrosive substances pose significant challenges to the performance and lifespan of motors.

For buyers seeking reliable power solutions, understanding how well a motor can withstand these tough conditions is crucial.

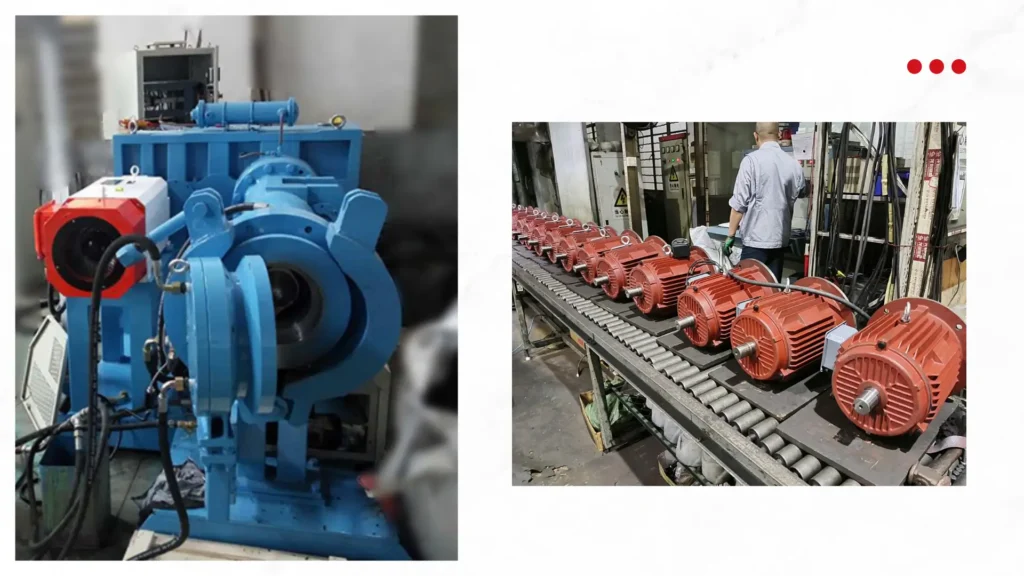

Rare Earth Permanent Magnet Synchronous (PMS) Motors have emerged as a top choice due to their remarkable adaptability in harsh environments.

This article will provide an in – depth look at how these motors overcome environmental challenges, offering valuable insights for those considering purchasing them.

What Makes Harsh Environments Challenging for Motors?

Extreme Temperature Fluctuations

Harsh environments frequently feature extreme temperature variations, from scorching heat to freezing cold.

High temperatures can cause motor components, such as insulation materials and magnets, to degrade, reducing efficiency and potentially leading to breakdowns.

On the other hand, extremely low temperatures can make lubricants thicken, impeding smooth operation and increasing mechanical stress on the motor.

High Humidity and Moisture

Excessive humidity and moisture are common in certain harsh environments, like coastal areas or regions with high rainfall.

Moisture can seep into motor components, causing rust and corrosion of metal parts. It can also damage electrical insulation, increasing the risk of short circuits and electrical failures.

Dust, Debris, and Corrosive Substances

Environments filled with dust, sand, or debris can clog motor vents and cooling systems, leading to overheating.

Corrosive substances, whether they are chemicals in industrial settings or salt in coastal air, can eat away at motor housing and internal components, gradually weakening the motor’s structure and performance.

And More:

- Extending Lifespan: Preventive Maintenance Checklists for Industrial PMS Motors

- The Tesla Effect: How EV Innovations Are Shaping Rare Earth Motor Standards

How Do Rare Earth PMS Motors Handle Extreme Temperatures?

Heat Resistance Design

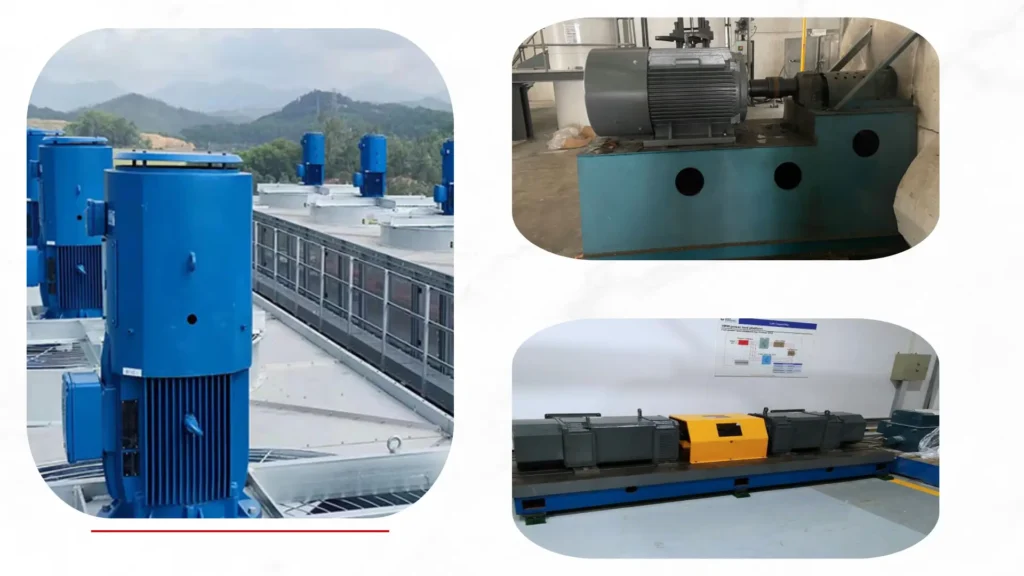

Rare Earth PMS Motors are engineered with heat – resistant materials and advanced cooling mechanisms.

High – quality insulation materials are used to protect the electrical windings from the damaging effects of heat.

Additionally, efficient heat dissipation designs, such as optimized fin structures on the motor housing or advanced cooling fans, help to keep the motor’s internal temperature within safe operating limits even in high – temperature environments.

Cold – Weather Adaptability

For cold – weather conditions, these motors are designed to maintain their performance.

Specialized lubricants with low – temperature fluidity ensure that moving parts can still operate smoothly.

The magnetic properties of rare earth materials used in the motors remain stable at low temperatures, allowing the motor to generate consistent torque and power without significant loss in efficiency.

Temperature – Sensing and Control Features

Many Rare Earth PMS Motors are equipped with temperature – sensing devices.

These sensors continuously monitor the motor’s temperature and can trigger protective measures if the temperature approaches critical levels.

For example, the motor’s speed may be automatically adjusted or it may be shut down temporarily to prevent overheating, ensuring its long – term reliability in extreme temperature conditions.

What Enables Rare Earth PMS Motors to Resist Humidity and Moisture?

Sealed Construction

One of the key features that make Rare Earth PMS Motors resistant to humidity is their sealed construction. The motor housing is designed to prevent moisture from entering the internal components.

High – quality gaskets and seals are used at joints and openings, creating a barrier against water and humidity. This sealed design protects the electrical and mechanical parts from rust and corrosion caused by moisture exposure.

Moisture – Resistant Materials

In addition to the sealed housing, these motors utilize moisture – resistant materials.

The electrical insulation is made from materials that have excellent resistance to water penetration.

Some motors may also use coated or treated metal parts that are less susceptible to rusting when exposed to moisture, further enhancing the motor’s durability in humid environments.

Condensation Management

To deal with potential condensation issues, Rare Earth PMS Motors may incorporate features for condensation management.

Drain holes or channels can be designed into the motor housing to allow any accumulated moisture to escape.

This prevents the build – up of water inside the motor, reducing the risk of electrical failures due to condensation.

How Do Rare Earth PMS Motors Cope with Dust and Debris?

Dust – Proof Enclosures

Rare Earth PMS Motors often come with dust – proof enclosures. These enclosures are designed to prevent dust, sand, and debris from entering the motor’s internal components.

Fine – mesh filters or sealed compartments are used to block the ingress of particles while still allowing for proper ventilation and cooling.

This ensures that the motor can operate in dusty environments without the risk of its cooling system being blocked or its moving parts being damaged by abrasive particles.

Self – Cleaning Mechanisms

Some advanced models of Rare Earth PMS Motors are equipped with self – cleaning mechanisms.

For example, certain motors may use vibration or air – blowing techniques to dislodge dust and debris that has accumulated on internal surfaces.

These self – cleaning features help to maintain the motor’s performance and efficiency over time, even in extremely dusty conditions.

Durable Bearing and Seal Designs

The bearings and seals in Rare Earth PMS Motors are designed to withstand the presence of dust and debris.

High – quality bearings with tight tolerances and robust seals prevent particles from getting into the bearing races, reducing wear and tear.

This durable design ensures that the motor can continue to rotate smoothly and efficiently, even in environments filled with abrasive materials.

What Are the Advantages of Rare Earth PMS Motors in Corrosive Environments?

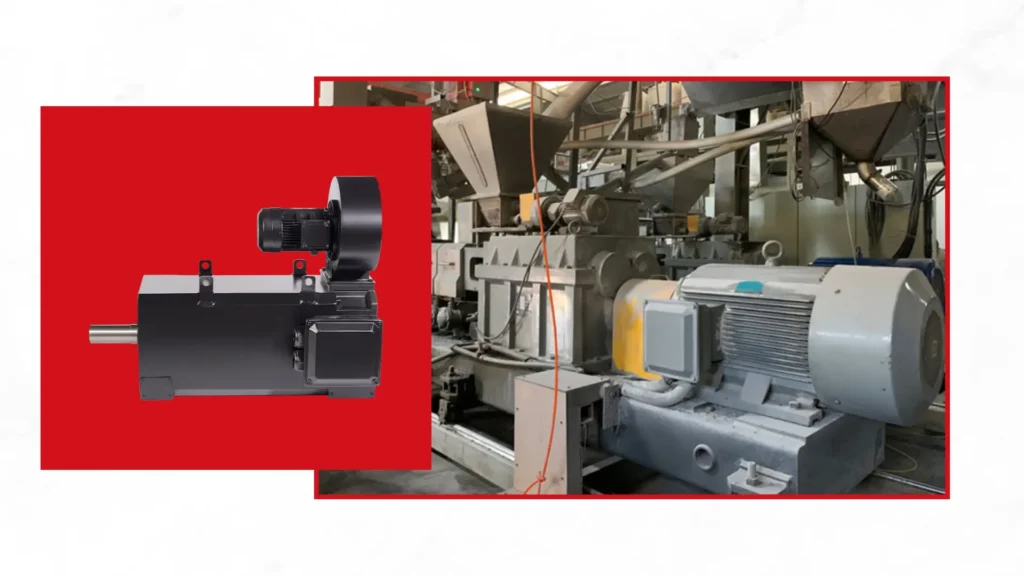

Corrosion – Resistant Coatings

To combat corrosion in harsh, chemically – laden or salty environments, Rare Earth PMS Motors are often coated with corrosion – resistant materials.

These coatings form a protective layer on the motor housing and exposed parts, shielding them from contact with corrosive substances.

Specialized paints, platings, or polymer coatings can significantly extend the motor’s lifespan in such challenging conditions.

Material Selection for Corrosion Resistance

The materials used in the construction of Rare Earth PMS Motors are carefully selected for their corrosion – resistant properties.

Stainless steel, non – ferrous metals, and corrosion – resistant plastics are commonly used in areas that are prone to corrosion.

By using these materials, the motor can resist the damaging effects of corrosive substances, maintaining its structural integrity and performance.

Isolation and Protection of Electrical Components

In corrosive environments, the electrical components of the motor need extra protection.

Rare Earth PMS Motors often feature isolated electrical systems, where the windings and other electrical parts are encapsulated or shielded.

This isolation prevents corrosive substances from coming into contact with the electrical components, reducing the risk of electrical failures due to corrosion.

Also Read:

- Material Showdown: Samarium-Cobalt vs. Neodymium in High-Temperature Motors

- Importing Rare Earth Motors to Nigeria: Customs Duties and Certification Tips

How Can You Maintain Rare Earth PMS Motors in Harsh Environments?

Regular Inspections

Regularly inspecting Rare Earth PMS Motors is essential in harsh environments.

Check for any signs of damage, such as cracks in the housing, wear on seals, or corrosion on metal parts. Inspect the cooling system for blockages caused by dust or debris.

Early detection of issues can prevent more serious problems from occurring and ensure the motor continues to operate reliably.

Cleaning and Lubrication

Clean the motor regularly to remove accumulated dust, debris, and any corrosive residues.

Use appropriate cleaning methods and solvents that are safe for the motor’s materials. Additionally, lubricate the moving parts as per the manufacturer’s recommendations.

Proper lubrication helps to reduce friction, prevent wear, and ensure smooth operation, especially in harsh conditions where components may be more prone to stress.

Component Replacement and Upkeep

Over time, some components of the motor may wear out or become damaged due to the harsh environment.

Replace worn – out seals, bearings, or other parts promptly to maintain the motor’s performance.

Keep spare parts on hand and follow the manufacturer’s guidelines for component replacement to ensure compatibility and optimal functionality.

What Does the Future Hold for Rare Earth PMS Motors in Harsh Environments?

Technological Advancements

As technology continues to evolve, we can expect even more advanced designs for Rare Earth PMS Motors in harsh environments.

Innovations in materials science may lead to the development of even more heat – resistant, moisture – proof, and corrosion – resistant materials.

Advanced manufacturing techniques could result in motors with improved sealing and more efficient cooling systems.

Integration with Smart Technologies

The future may see greater integration of Rare Earth PMS Motors with smart technologies in harsh environments.

Sensors and monitoring systems can be further enhanced to provide real – time data on the motor’s performance and condition.

This data can be used for predictive maintenance, allowing operators to address potential issues before they cause breakdowns, improving overall reliability and reducing downtime.

Expansion of Application Areas

With their proven adaptability, Rare Earth PMS Motors are likely to expand into new application areas in harsh environments.

As industries such as deep – sea exploration, mining in extreme terrains, and high – altitude wind energy generation grow, these motors may find new uses, driving further innovation and development in their design and functionality.

Conclusion

Rare Earth PMS Motors have demonstrated outstanding adaptability in harsh environments, overcoming the challenges posed by extreme temperatures, humidity, dust, debris, and corrosive substances.

Their unique designs, use of high – quality materials, and advanced features make them a reliable choice for a wide range of applications where conditions are tough.

By understanding how these motors perform in harsh environments and how to maintain them, buyers can make informed decisions, ensuring that they invest in a motor that will deliver consistent performance and long – term value, even in the most demanding settings.