In emergency situations, every millisecond counts. Whether it’s a sudden power outage triggering backup generators, a fire door slamming shut to contain flames, or a critical industrial valve closing to prevent leaks, the ability to act instantly can mean the difference between safety and disaster.

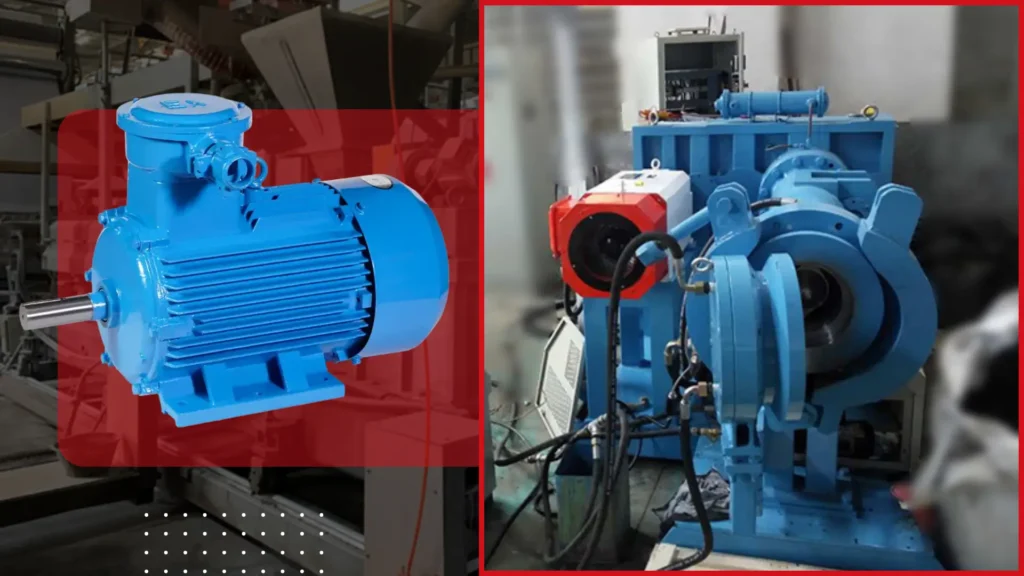

This is where high-response rare earth permanent magnet synchronous motors (PMSMs) shine.

Designed to deliver torque the moment they’re activated, these motors are becoming the backbone of modern emergency systems.

Let’s break down how they work, why they matter, and what makes them indispensable for reliability when it matters most.

What Makes a Motor “High-Response” in Emergency Scenarios?

Defining response time in practical terms

Response time, in simple terms, is how quickly a motor goes from “off” to “full action.”

For emergency systems, this isn’t just about speed—it’s about consistency. A high-response motor doesn’t hesitate; it starts moving within fractions of a second, with no lag between the signal to activate and the actual movement.

Why “instant” matters more than “fast”

In emergencies, “fast” isn’t enough. If a motor takes even half a second longer than needed to close a safety gate or start a pump, the window for preventing harm shrinks dramatically.

Instant response ensures that systems act before a small issue escalates into a crisis.

How rare earth materials boost this responsiveness

Rare earth elements, like neodymium, create extremely strong magnetic fields in the motor.

These powerful magnets allow the motor to generate force almost immediately when electricity flows through its coils, eliminating the delays common in older motor designs that rely on weaker magnets or slower magnetic field buildup.

What Sets Rare Earth PMSMs Apart from Regular Motors?

The role of permanent magnets in simplifying operation

These magnets are always “on,” so the motor doesn’t waste time building up a magnetic field—it’s ready to react the second power is applied.

This instant responsiveness is crucial in emergencies, such as when a fire alarm triggers a sprinkler system, where even a split-second delay could escalate risks.

Operators also benefit from streamlined controls, as there’s no need for complex mechanisms to activate the magnetic field, reducing the chance of human error during critical moments.

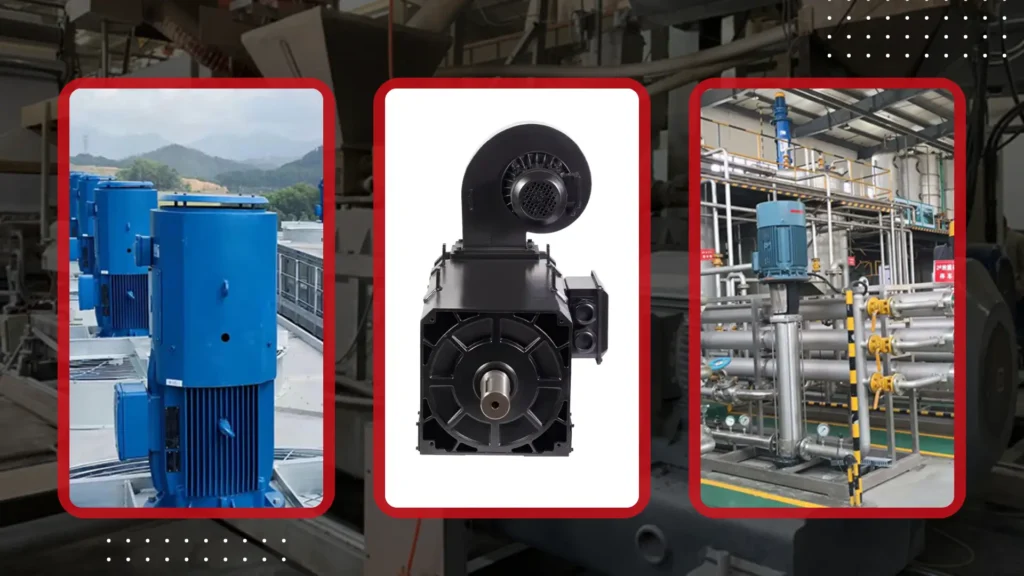

Size vs. power: A key advantage for tight emergency setups

Rare earth PMSMs pack more power into a smaller space. Emergency systems often have limited room—think underfloor backup units or compact fire suppression panels.

These motors deliver the necessary strength without requiring bulky housing, making them easy to integrate into tight spaces.

This space-saving design also allows for more flexible installation in older buildings, where retrofitting emergency systems with large equipment would be impractical.

Energy efficiency in short bursts

Emergency systems don’t run 24/7—they activate only when needed. Rare earth PMSMs are designed to use energy efficiently during these short, intense bursts, ensuring they don’t drain backup power sources unnecessarily while still delivering maximum torque.

This efficiency is a lifesaver in remote areas where recharging backup batteries is challenging, as it extends the lifespan of power reserves between charges.

Moreover, it minimizes the need for frequent battery replacements, cutting down on maintenance costs and ensuring the system is always ready to perform when called upon.

And More:

- Key Features of Permanent Magnet Synchronous Motors (PMSMs)

- Permanent Magnet Synchronous Motor Price Comparison

- Overview of Permanent Magnet Synchronous Motors in China

How Does Instant Torque Work, and Why Is It Critical?

Torque explained: The “muscle” behind movement

Torque is the rotational force that makes things move—think of it as the “muscle” of a motor.

In emergency lifts, it’s the torque that swiftly raises or lowers the car, ensuring people are evacuated without delay.

Even in small devices like emergency lighting rotators, torque controls the smooth swivel, making sure light covers every critical corner.

Avoiding delays in critical moments

If a motor builds torque slowly, a fire door might take seconds to close fully, letting smoke or flames spread. Instant torque ensures the door slams shut in the blink of an eye, containing the danger right away.

In a chemical spill scenario, the torque that seals off ventilation ducts acts just as fast, preventing toxic fumes from spreading through the building.

For emergency shut-off valves in industrial settings, instant torque cuts off hazardous flows before they escalate into major disasters.

Torque consistency under varying conditions

Emergency environments are unpredictable—temperatures might spike, or power supplies might fluctuate.

Rare earth PMSMs maintain steady torque even in these conditions, so they don’t weaken or slow down when stressed.

Even when backup batteries start to drain, the consistent torque ensures that critical tasks like lowering a rescue ladder or activating a siren aren’t compromised.

Why Are Rare Earth Materials Essential for This Performance?

Strength of rare earth magnets compared to alternatives

Rare earth magnets are exponentially stronger than older options like ferrite magnets.

A small rare earth magnet can produce the same magnetic force as a much larger ferrite magnet, allowing motors to be both compact and powerful.

This size-to-strength ratio is a game-changer in emergency medical equipment, where space is precious but reliable power is non-negotiable.

How their magnetic properties enable quick torque buildup

The strong, stable magnetic fields of rare earth materials mean that when electricity flows through the motor’s coils, the interaction between the magnetic fields happens almost instantly.

There’s no “warming up” period—torque is generated the moment the current starts. This rapid response is vital in emergency door release systems, where a split-second delay could trap people in dangerous areas.

It also ensures that backup generators kick into full power the moment the main supply fails, preventing costly or life-threatening gaps in service.

Durability in harsh emergency environments

Rare earth magnets are resistant to demagnetization, even in high heat or vibration—common in emergencies like fires or equipment failures.

This durability ensures the motor performs reliably when other components might falter.

In the chaos of a building collapse, where vibrations rattle every piece of equipment, these magnets keep the motor’s core functionality intact.

Even when exposed to the extreme heat of a warehouse fire, they maintain their magnetic strength, ensuring sprinkler systems and emergency elevators continue to operate when needed most.

Also Read:

- Hidden Value of Rare Earth PMS Motors: Boosting Productivity in Assembly Lines

- Wide-Speed Range Rare Earth PMSM: Adaptable to Variable Workload Scenarios

Can These Motors Handle the Stress of Emergency Systems?

Built to withstand sudden, frequent activation

Emergency systems might sit idle for months, then activate repeatedly in a single crisis.

Rare earth PMSMs are engineered to handle these “on-off” cycles without overheating or wearing out prematurely.

Tolerance for extreme temperatures and conditions

From freezing cold in outdoor backup generators to the heat of a chemical plant emergency, these motors are tested to operate in a wide range of temperatures.

Their components resist corrosion and damage, ensuring they work when the environment is at its worst.

Long-term reliability with minimal maintenance

Unlike motors that need regular lubrication or part replacements, rare earth PMSMs have fewer moving parts and durable components.

This means less downtime for maintenance—a crucial feature for systems that must be ready 24/7.

How Do These Motors Integrate with Existing Emergency Systems?

Compatibility with standard control signals

High-response rare earth PMSMs are designed to work with the same control systems used in most emergency setups, like fire alarms or power outage sensors.

They don’t require complex rewiring or custom programming, making integration straightforward.

This seamless compatibility means facilities can upgrade their motors without overhauling existing safety infrastructure, saving both time and money during installation.

Sizing flexibility for different system designs

Whether a system needs a tiny motor to operate a small valve or a larger one to power a backup elevator, these motors come in a range of sizes.

This flexibility ensures they can fit into almost any emergency setup without major redesigns.

In compact server rooms, a small-sized motor can efficiently control ventilation dampers, while a larger model can drive heavy-duty emergency exit gates in stadiums.

This adaptability eliminates the need for custom-engineered solutions, allowing quick deployment across diverse facilities.

Power source adaptability

Emergency systems often rely on backup power—batteries, diesel generators, or solar backups.

Rare earth PMSMs are efficient enough to run on these limited power sources, ensuring they activate even when the main grid is down.

Their low energy draw means a single battery pack can keep critical motors running for hours, providing ample time for evacuations or repairs.

Even in remote locations where solar is the primary backup, the motors convert stored energy into reliable motion without waste, ensuring no loss of functionality when it matters most.

And More:

- Advantages of Permanent Magnet Motors in Emergency Power Generation

- Applications of Permanent Magnet Motors in Solar Power Generation Systems

What Makes Torque Output “Instant” in Real-World Use?

The science of zero-latency signal processing

Modern rare earth PMSMs use advanced electronics to process activation signals instantly.

There’s no delay between the system detecting an emergency and the motor receiving the “go” command—they communicate in real time.

Eliminating mechanical lag with precision engineering

Older motors have parts that need to “catch up” (like heavy rotors or loose connections), causing lag.

Rare earth PMSMs are built with lightweight, perfectly balanced components that start moving the moment force is applied.

Real-time adjustment to changing demands

In some emergencies, the required torque might change—for example, a door might need to close faster if wind is pushing against it.

These motors adjust their output on the fly, ensuring consistent performance even when conditions shift.

Why Should Emergency System Operators Prioritize This Technology?

Reducing risk with faster emergency activation

Faster activation directly lowers the risk of damage, injury, or loss. A motor that closes a valve 0.5 seconds faster can prevent hundreds of liters of hazardous fluid from leaking, or a fire door that shuts instantly can contain smoke to protect evacuation routes.

In chemical plants, this split-second difference can mean the difference between a minor spill and a full-blown explosion, safeguarding workers and nearby communities.

Even in residential buildings, quicker activation of sprinkler systems can douse a small fire before it spreads to other rooms, minimizing property damage and saving lives.

Lower long-term costs through reliability

Rare earth PMSMs are less likely to fail, meaning fewer replacements and repairs.

This reliability translates to lower maintenance costs compared to less durable motors that might break down when needed most.

Over the lifespan of an emergency system, the savings from reduced downtime and part replacements can add up to thousands of dollars, making the initial investment in these motors a cost-effective choice.

Meeting evolving safety standards

Safety regulations are getting stricter, requiring faster response times from emergency systems.

High-response rare earth PMSMs help operators meet these standards effortlessly, avoiding penalties and ensuring compliance.

As governments and industry bodies update safety codes to address new risks, these motors provide a future-proof solution that can adapt to higher performance requirements without needing complete system overhauls.

This compliance not only keeps facilities on the right side of the law but also enhances their reputation as safe and responsible operators.

Conclusion

In emergency systems, reliability and speed aren’t just features—they’re lifelines. High-response rare earth PMSMs deliver both, with instant torque output that turns critical signals into immediate action.

They provide peace of mind to facility managers, knowing that when disaster strikes, the equipment will perform as expected.

For anyone responsible for keeping people, facilities, or equipment safe during crises, investing in this technology isn’t just a choice—it’s a commitment to being ready when every second counts.