Efficiency is indeed one of the most essential features people take into accoucl, when they go for an electric motor.

Firstly, it entails decreased energy consumption, hence reduces the operating expenses and protects the environment.

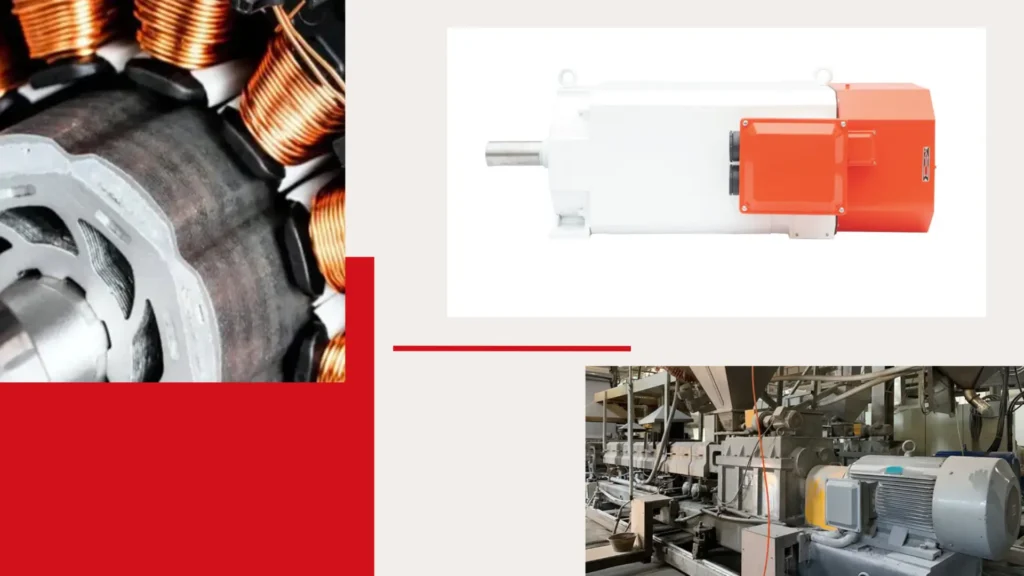

The designs of such motors, PMMS, in all intensive application of electric motor technology range especially in the improvement of performance characteristics and efficiency improvement vis a vis cost factors.

Anyway, for technologically advanced enterprises and corporations, the use of such motors is an investment in their present as well as future sustainability because the motors especially the higher efficiency motors are supposed to aid them conserve energy.

Learn More:

- A Comprehensive Guide to Permanent Magnet Synchronous Motor Wholesale in China

- A Comprehensive Guide to PMSM Manufacturers in China

- The Difference Between Permanent Magnet Synchronous Motors

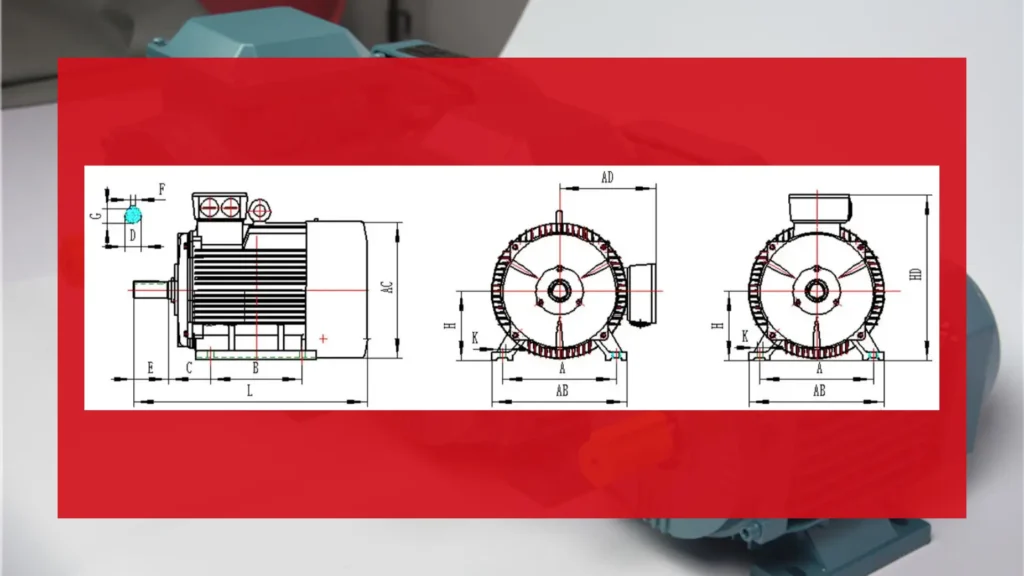

Understanding Motor Specifications

Factors to Look Out for

A comprehensive understanding of a PMM such as its specifications is crucial when deciding on the best PMM.

Key specifications that also help in deciding the right PMM, include the power output, efficiency rating, torque, and the size constraints.

Each one of these including many power rating, influence heavily on the degree of performance that can be achieved by the equipment in the intended application, with on the proper specification of the suitable motor hesitating performance these performance gains could be ambitiously placed into the question.

Power Output

One further prominent detail which denotes by itself the performance worthiness of this particular motor is the power.

Power which is measured in watts or horsepower even makes provision to have power load.

Most importantly it is of significance to identify correct specific-rated power. should you end up with more power the one needed the extra watt may just be a waste of resources whether if you have less power than what is required, then there is no achieving the performance as it is intended to be.

Given the above, it is essential to estimate the power of your equipment correctly before selecting the suitable PMM.

Motor Efficiency

Efficiency ratings function as a point of reference for how effectively a rotating machine converts electrical energy into useful output, which includes components such as mechanical energy and often includes electrical energy.

An electric motor can be considered to be a high-efficiency device if its efficiency is above 90%.

The benefit of increased efficiency is not only reduced energy expenditures, but also reduced negative effects on the environment.

This is important because it enables one to rate the technologies and services according to their ability confine the use of energy.

Performance Lexicons

Torque is simply the force that makes a rotating shaft turn and it is a critical component for any system that needs particular torque values for a certain speed and load conditions.

Beside these knowledge, understanding the torque-speed curve helps in anticipating if given motor will be appropriate in the given application.

In particular motors that have good starting torque are expected to come in handy where there is a need for high acceleration or high load.

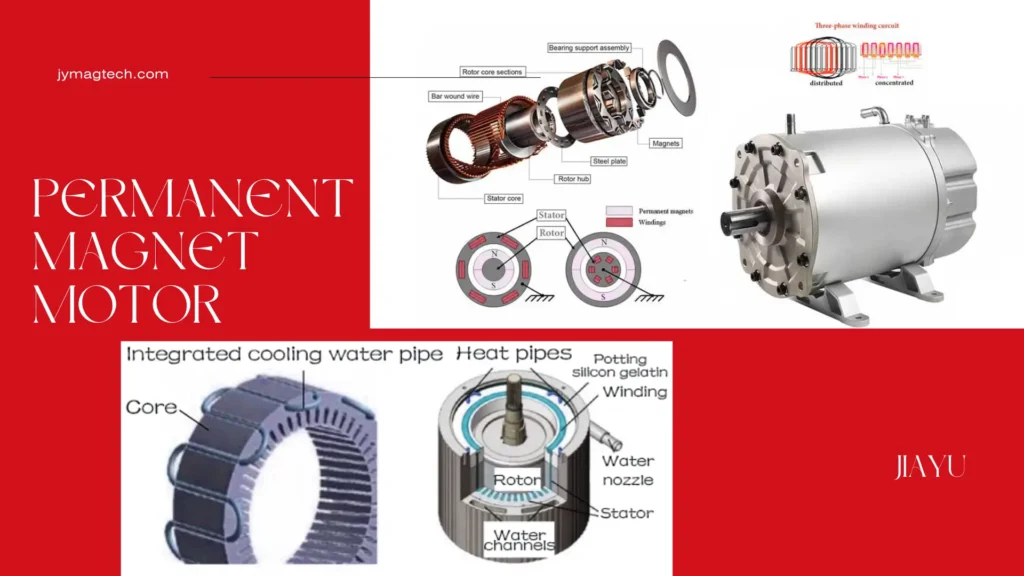

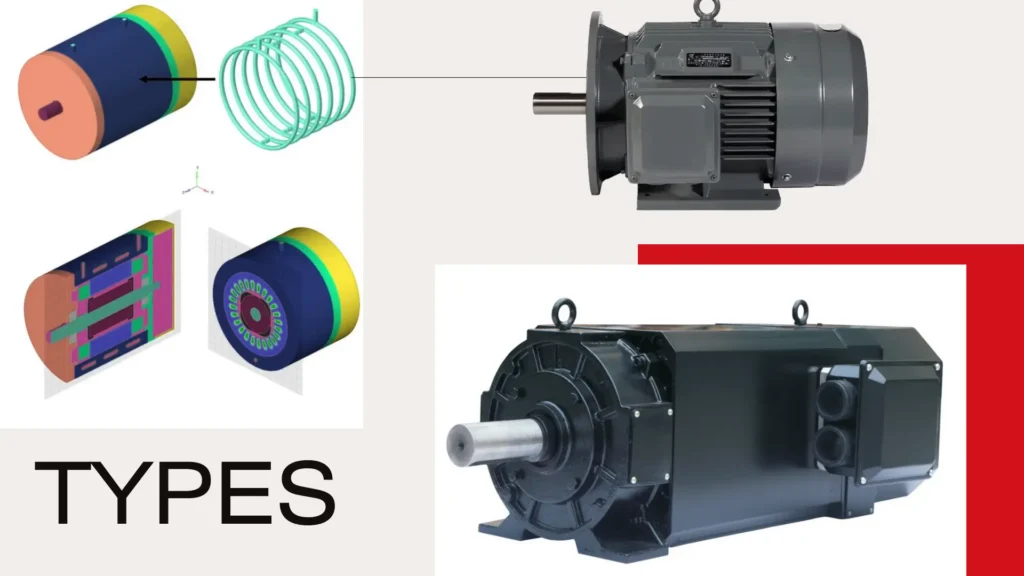

Types of Permanent Magnet Motors

Synchronous vs. Asynchronous

Synchronous motors are designed to operate at a fixed speed that directly matches the frequency of the power supply.

Therefore, making them a great choice for tasks, which need precise regulation of the speed. In contrast, asynchronous motors change their speed depending on the influence of the working load.

Recognizing these distinctions allows for the possibility of choosing the right motor depending on the speed and the application.

Surface-Mounted verses Interior Permanent Magnet Motors

The design of surface mounted motor is often simple, thus more cost-effective and can be used for a range of applications.

However, the decision between the two would be determined by the specific of performance considerations as applied by the purpose.

Applications of Different Types

Each of the different types of PMMs is appropriate for particular applications.

It is common knowledge that synchronous motors are widely being favored in applications where there is need to maintain a constant speed and very accurate position, as for example in robotics or conveyor systems.

On the other hand, practical applications employing Asynchronous motors are many since fans or pumps for example run at varying speeds.

It is always necessary to understand which kinds of applications are best suited to the type of a particular electric motor so that the highest levels of efficiency can be achieved.

Benefits of High Efficiency PMMs

Cost Management

A good number of individuals normally find it sensible as a result of the massive benefits, that it is wise to pump more resources in high efficiency

PMMs simply as a result of the cost that can be saved.

Due to less energy demand, such motors also play their part in greatly reducing utility costs which is turn creates a fast payback period.

However, the money saved over time can build up to large proportions hence enhance the financial status of an establishment.

Environmental Interconnection

Use of highly efficient motors is less taxing to the environment since less energy is consumed and hence less carbon dioxide is emitted in the atmosphere.

There are businesses that consider sustainability as a core corporate value and in such cases the promotion of PMMs is likely to enhance corporate reputation, promote cause marketing and assist in the interpretation of various laws.

Employing these strategies is not bothersome to the relevant parties and instead largely contributes horning them in the right direction in making choices in favor of the environment.

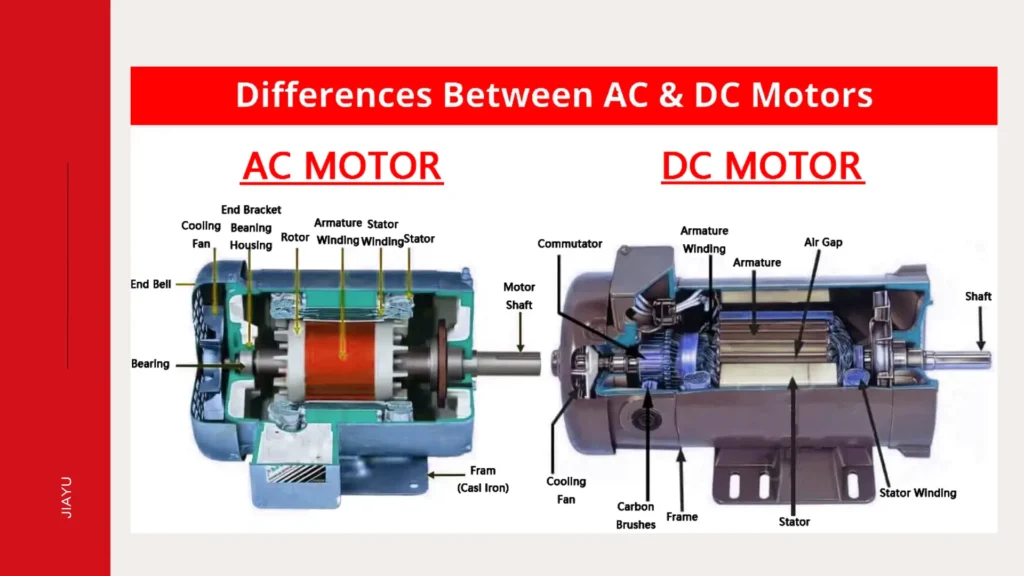

Useage Time and Repair

Such a equipment are known for high levels of service and low consumable costs.

Because of the absence of consumables such as brushes and wearing components, the lifetime of high-efficiency permanent magnet motors is higher than that of normal motors.

That increased duration comes with reduced maintenance charges since there are no additional charges on the consumables, also this increases the less or no downtime and ensures high levels of productivity once again.

Selecting the Right PMM

Checking Your Demands

First and foremost, it is crucial to look at the requirements from the operation perspective before choosing a PMM.

This includes the study of the characteristics of load, constraints with space, the available funds, etc.

Knowing these things well makes it easier to figure out what type of motor would be best for the purpose hence more effective and reliable.

Seeking Professional Help

By interacting with the motor builders, either direct or through experts, the user is able to get some information that could help in the choice of the optimal PMM.

Experts can also assist you in design changes explaining how this affects the performance of a motor.

This calls for such professionals as experts in their areas of specialization to avoid guesswork.

Evaluating Alternatives

Selecting the permanent magnet motor involves review of individual specs as well as the selection of better suppliers and models.

Specifications and efficiency ratings matter a lot in the selection of a motor from the customer feedback.

A comprehensive assessment of the different motors available would help in choosing the most ideal motor and not any other which could be unhelpful in the long run.

Installation Considerations

Space Requirements

Before you start installing the PMM or any associated equipment, you have first to consider the space requirements the motor or accessory takes up.

Having an adequate arrangement to provide cooling to such machinery and to give it sufficient access in case it requires any maintenance is critical in ensuring the smooth operation and the last ability of the performance.

Planning for this would avoid the problem on the technical operation thereof in the future.

Operational Aspects

The new motor should be as compatible as possible in relation with the power supply and the main line mechanical brain of the systems.

Any omission in these regards could have a serious negative impact resulting in an important loss of production; therefore, it is necessary to check new motor one is going to install will blend in well with existing devices.

Industrial Safety Regulations

Furthermore, it is mandatory to evaluate the safety compliance factors concerning the motor both local and global.

Feel the need to mention that obedience to these codes not only ensures your employees and machinery are not harmed but also saves your organization from liabilities aligned safety non compliance issues.

Maintenance and Care

Maintenance Schedule

Ensuring that your PMM is inspected regularly is critical for identifying any pending concerns.

It is advised that effort is made in regular inspections as it ensures the motor is working efficiently, thus extending its life.

The setting of a maintenance timeframe will be useful in ensuring that your motor is well maintained.

Cleaning and Upkeep

Tending to the motor, varnishing it and ensuring no dirt and foreign objects have lodged in it is vital to ensure that it continues performing in an optimal capacity.

Cleaning or spraying it should also be done based on the directives from the manufacturer.

Maintenance should always be done to ensure that everything is functioning well and helps to prevent overuse of materials.

Upgrading Components

Another thing is, if the technology does not stop getting better, select and put more advanced and efficient solutions in the motor system, while they are still revision, rather than waiting until such solutions are already so common that the need for constant changes does not affect your company and helps it sound more efficient to its customers.

Summary

DWM Technologies LLP service provider in India markets and researches high Performance PM Motors that improve the performance and Environmental responsibility at levels comparable to a turbo machinery compressor.

In other words, it is for you to assess which motor best meets your performance requirements with minimum environmental impact and costs.

Consequently, it is important to be aware of what is there in terms of the developments in motor technology.

Developments continue in design and materials such that PMMs are getting even more efficient than before.

Such changes to the economic landscape will guide your decision making of your investments in the business.