Permanent magnet synchronous motors (PMSM) are basically electronic motors powered by permanent magnets to produce a magnetic field.

It is a replacement of old DC motors, which changed the way the electromagnetic field was induced in stator windings.

This has the maximum efficiency, almost zero losses, and the higher performance making it popular in a variety of applications.

The PMSM comprises major parts, for example, rotor, stator, and permanent magnets. The rotor has embedded permanent magnets.

It rotates inside the casing to produce mechanical power. This mechanical power drives the action of the motor through machinery and equipment with great efficiency.

PMSM functions within electromagnetic induction principles. In the stator windings, electrical current is passed through them.

A magnetic rotating field is generated by the same. When the said field comes into contact with the static magnetic field present at the rotor’s permanent magnets, the rotor starts to rotate.

Many applications have tremendous advantages because the synchronous motion remains at a constant speed for a PMSM.

Why Choose Permanent Magnet Synchronous Motors Over Traditional Motors?

Efficiency Advantages

The fact that the PM Synchronous Motors (PMSMs) can achieve energy savings of more than 90% compared to traditional induction motors is their best advantage.

Its resultant low operational cost and carbon footprint reduction actually indicate high efficiency.

Performance Advantages

With higher torque and better speed regulation, PMSMs performance is already excellent.

Precise control over speed and position makes PMSMs a good choice for performance and reliability in a wide range of high-grade applications.

High precision leads to increased productivity and smoother operation.

Long-lasting And Reliable

PMSM warranties assure very high durability and long life in operation.

Lack of brushes which reduce wear and tear and significantly reduce maintenance needs and fewer breakdowns.

Due to their reliability, the costs are additionally reduced over time, with more business resources to spend on repairs and downtime.

How Can PMSMs Lead to Cost Savings?

Decrease of Energy Consumption

One of the biggest advantages regarding saving costs when using PMSM is their low consumption of energy. Their high efficiency implies the consumption of fewer amounts of energy to reach the same output, which further benefits the company as lower utility bills mean sustainability, even in operations.

Lower Costs of Maintenance

PMSMs need less maintenance than traditional motors thanks in part to their robust design and fewer moving parts. This reduces costs involving repairs and prevents unexpected failures, which may cause serious disruptions in the operation of the system.

Longer Operational Time

The fact that they have a longer life than their ancestors is another blessing that PMSMs have.

The existing life ensures that companies would not need subsequent expenses for the continual replacing of motors, thereby saving a lot in the long run.

What Industries Benefit Most from PMSMs?

Manufacturing and Automation

The application of the PMSM in the area of manufacturing is really awesome as it increases accuracy and effectiveness.

As it is continuously running, it provides faster performance and is also very cost effective when high consistency is required for automated systems.

Renewable Energy

The PMSMs perform a significant role in the renewable energy applications related to wind turbines and solar inverters.

It adds towards ensuring better energy brought about by the enhancement of sustainability goals in those industries.

Electric Vehicles

This is one of the rapidly growing sectors of the employing of PMSMs-fuelled electrical systems.

These high-performance and high-efficient type vehicles increase their range and also efficiency and hence become a hot pick for auto industry manufacturers.

How Do PMSMs Reduce Energy Costs?

Better Efficient Ratings

PMSMs have higher efficiencies than traditional motors and in this sense have direct energy savings benefits.

This special feature of efficiency is most advantageous when machines are in continuous operation, as well as for those that are subject to variable loads.

Regenerative Braking

Many designs of PMSMs have been configured Rs into regenerative-mode systems with energy recovery during braking.

Features that contribute to better energy efficiency and cost savings are less wear of the brake components due to braking.

Excellent Performance with Varying Loads

PMSMs are a success in variable load applications because different output is generated to match the demand of a particular use without losing efficiency or electric energy, ergo saving money for the end-user.

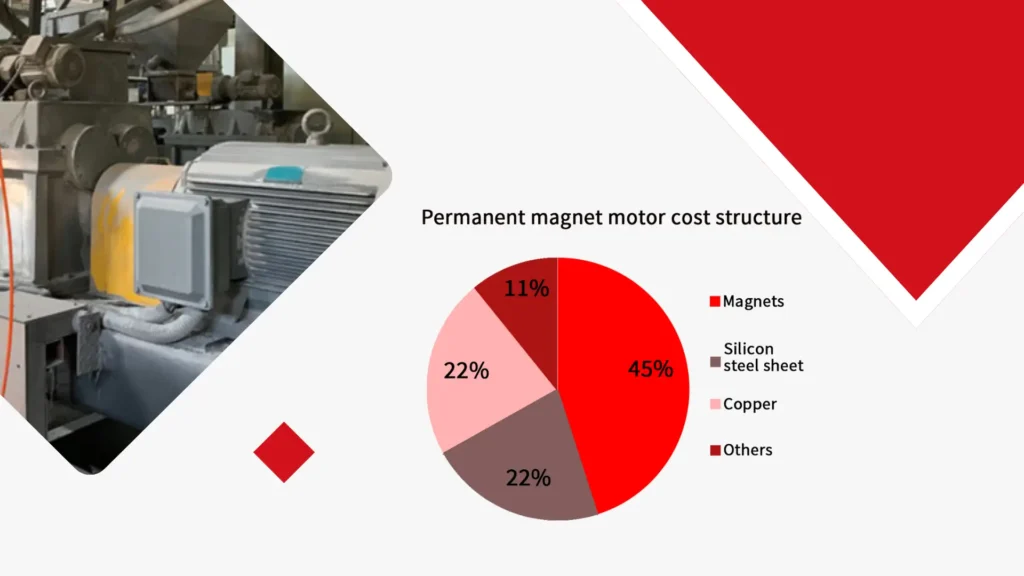

What Are the Initial Costs and Long-Term Savings?

Investment Analysis from the Start Consideration

The long-term savings that PMSMs often realize often justify their higher acquisition price compared to other motors.

Besides just the upfront costs, businesses need to take into account the potential savings on lower operating expenses and maintenance costs.

Return on Investment (ROI) Evaluation

Looking at ROI analysis, a well-executed ROI analysis can get the value out of these motors for a business using PMSMs, energy savings, reduction in maintenance costs, and increased operating efficiency.

Comparison of Total Cost

The other important factor lies in the total cost of owning belongings that include the purchase price, costs of running, and maintenance costs.

PMSMs, because they are more efficient and last longer, often result in a very advantageous TCO instead.

How to Select the Right PMSM for Your Needs?

Appraising Specific Application Demands

Choosing the right PMSM begins with knowing the specific requirements of your application.

To achieve that, think about issues such as load capacity, speed, and environmental factors to make sure you the motor meets your demands.

Consultation with Experts

Getting a good Insight on how to choose the best PMSM, with several options at disposure, can be achieved working industry experts.

They should lead you through the many options and, in particular, help you understand the technical specifications essential to your application.

Exploring Different Models

Here with several PMSM models, it is crucial to compare various selections for performance, efficiency, and cost.

It will be very important to look for the most balanced model in terms of features and cost in terms of function type and price to satisfy the needs of the operation.

What Are the Future Trends in PMSM Technology?

Material Innovations

Research in today’s material science and technology is making better and stronger magnets to further enhance the performance and efficiency of future motors.

Integration with Smart Technologies

PMSMs are smartly produced and automated in future industries and smart technology with better control systems.

The Environment: Ecology

They are now considered ideal for more energy-friendly and environmentally friendly businesses.

Their response in reducing energy use by using electricity generates additional savings in greenhouse gas emissions, too, thus promoting corporate sustainability.

How Can You Get Started with PMSMs?

Differentiating One from Multiple

The first step in moving to PMSMs is to differentiate between an existing single motor system and multiple one.

Identifying performance and areas of micro-precision improvements will make sure you know the benefits you get from moving to PMSMs.

Discussing the Process with Suppliers

Cultivating associations with reputable vendors will facilitate the smooth transition to PMSMs.

These suppliers could give the best models that are available as they possibly can help in installation and support.

Planning for Implementation

Lastly, a detailed implementation plan is required in order to ensure that the transition to PMSMs is successful.

This plan needs to detail timelines and budget aspects while offering training to ensure that staff is competent for easy integration of PMSMs into the work in the most sensible manner.

Conclusion

In general, Pemanent Magnet Synchronous Motors (PMSMs) could convince companies searching for efficiency, lower operational expenses, and better performance.

Because of high efficiency, less required maintenance, and very long-living motors, these motors offer a tremendous advantage over traditional motor technologies.

Not only does reducing energy consumption, it consumes in practice lessen energy consumption as part of companies’ contracted corporate responsibility targets.

They might entail high investment at first in PMSMs, but energy cost savings and reduced maintenance can make overall savings be higher.

This is possible through thorough assessment of needs, assistance in assessing these needs from a professional, and installation planning.

It is only when technological advancements are seen that PMSMs will be integrated into myriad applications within end-user sectors, from industrial manufacturing to the production of renewable energy, as well as to applications in electric vehicles.

Thus, embracing this innovative motor technology can lead to huge savings in costs and the creation of very sustainable operations for an enterprise.