When choosing a permanent – magnet motor for a particular application, a thorough analysis of diverse application requirements is crucial for ensuring the motor’s efficient operation and suitability.

Opting for permanent – magnet motors that align with the required power, speed, and environmental adaptability can remarkably boost the operational efficiency and stability of production equipment.

Take chemical production as an example.

Permanent magnet motors with high – temperature and corrosion – resistant properties guarantee continuous production, minimize equipment failure rates, improve product quality and output.

Consequently, this enhances the company’s market competitiveness and generates greater economic benefits.

Application Requirements

Torque and Speed

Determining the torque and speed required to perform tasks is the primary step.

This requires a comprehensive consideration of load conditions, acceleration and deceleration requirements, and the desired operating speed.

1.Load

Different load characteristics, such as load weight and inertia, directly determine the torque required by the motor.

For example, in a crane application, to lift heavy objects, the motor must have sufficient torque to overcome the load gravity and related resistance.

2.Acceleration/Deceleration

Rapid acceleration and deceleration processes require the motor to respond quickly and provide high torque.

For instance, robotic arms on an automated production line need to complete acceleration and deceleration actions in a short time to achieve efficient operation, which places high demands on the motor’s torque response ability.

3.Desired Operating Speed

Depending on the application scenario, the motor needs to meet specific operating speeds.

For example, a high – speed centrifuge requires the motor to maintain a high and stable rotational speed for efficient separation.

Duty Cycle

Evaluate whether the motor will operate continuously or intermittently (with on/off cycles).

In the case of intermittent operation, due to the cooling time during operation, a smaller – sized motor can be selected.

example, in some periodically operating equipment, such as an automatic door control system, the motor does not operate continuously.

By taking advantage of the cooling phase during intermittent operation, a smaller – sized motor can be used, thus saving costs and space.

Operating Environment

The operating environment factors of the motor have a substantial impact on its selection.

Factors such as temperature, humidity, and potential pollution risks (such as dust and debris) all need to be taken into account.

1.Temperature

Extremely high temperatures may weaken the magnetism of the permanent magnet, reducing the efficiency and performance of the motor.

Low temperatures, on the other hand, may affect the motor’s lubrication and increase mechanical friction.

For instance, in a high – temperature steel – making workshop or a low – temperature cold storage environment, the motor must have corresponding high – temperature – resistant or cold – resistant designs.

2.Vibration and Shock

The motor’s structure should be designed to endure mechanical stresses from the environment, especially vibration and shock.

In places like construction sites, mines, and where large – scale machinery operates, the motor may face intense vibration and shock.

Continuous vibration can loosen parts inside the motor, such as screws and windings.

This causes poor electrical connections and more mechanical friction, so the motor can’t work properly. Sudden impacts might directly damage the motor’s structure, for example, cracking magnets or deforming the casing.

Therefore, for permanent – magnet motors in vibrating and shock – prone environments, special designs and reinforcement measures are needed.

These include using vibration – absorbing pads, strengthening the housing, and optimizing how internal parts are fixed.

This helps the motor withstand mechanical stresses and operate stably and reliably in tough mechanical conditions.

3.Pollution

Dust and debris entering the motor may accumulate, affecting heat dissipation, or intensify the wear of mechanical components.

In dusty mines or processing workshops with debris, the motor should be equipped with dust – proof protection devices.

Power Supply

When using permanent magnet motors, determining the appropriate power supply is of crucial importance.

We need to figure out the available power supply type, whether it is alternating current (AC) or direct current (DC), and also understand its characteristics, such as voltage and current.

AC power is commonly employed in large – scale industrial applications.

It should be noted that its characteristics, including voltage and frequency, must match those of the motor.

It’s like finding a pair of suitable “shoes” for the motor; otherwise, it can’t operate properly.

example, many large – scale machinery and equipment in factories use AC power. If the voltage and frequency of the power supply don’t match the motor, the motor won’t be able to work normally.

DC power, on the other hand, is widely used in some applications with high – speed – regulation requirements, such as the drive systems of electric vehicles.

Electric vehicles need to accelerate and decelerate flexibly, and this requires the DC power supply to cooperate with the motor to precisely adjust the speed.

Control Requirements

Consider whether the application requires precise speed or position control, which may determine whether to select a servo motor or a stepper motor.

For example, in the processing of CNC machine tools, to ensure machining accuracy, precise control of the tool position is required.

At this time, the servo motor becomes an ideal choice due to its high – precision position control ability;

while in some automated equipment with precise angle positioning requirements, the stepper motor can achieve accurate positioning by precisely controlling the pulses.

Analysis of Permanent Magnet Motor Characteristics

Power Density

Power density represents the power that a permanent magnet motor can output per unit volume or weight.

Thanks to its unique magnetic circuit design and material properties, permanent magnet motors often feature a high power density.

In fields where strict restrictions are imposed on equipment volume and weight, such as aerospace and electric vehicles, permanent magnet motors with high power density have significant advantages.

For example, in unmanned aerial vehicles (UAVs), the compact and lightweight permanent magnet motors can output sufficient power to ensure the stable flight of UAVs, which benefits from their excellent power density.

It not only determines whether the motor can be adapted to application scenarios with specific space and weight requirements but also serves as one of the key indicators to measure the motor’s performance.

Efficiency

Permanent magnet motors exhibit remarkable efficiency, especially under partial load and within a wide speed range, where they can maintain a high energy conversion efficiency.

This mainly stems from their permanent magnet excitation method, which reduces excitation losses.

High efficiency means that, with the same input power, permanent magnet motors can output more mechanical power, reducing energy waste.

For various driving equipment in industrial production, for instance, permanent magnet motors that operate continuously can save a significant amount of electricity costs for enterprises due to their high efficiency.

In the long run, this greatly reduces operating costs and is also in line with the current development trend of energy conservation and environmental protection.

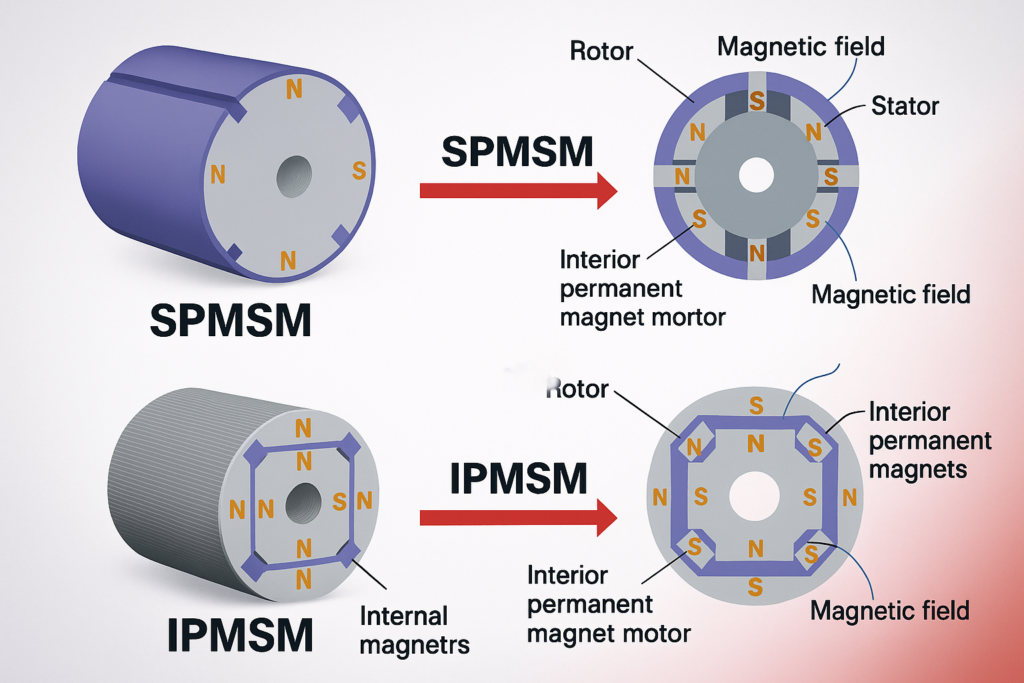

Motor Types (Surface Permanent Magnet Synchronous Motor – SPMSM vs. Interior Permanent Magnet Synchronous Motor – IPMSM)

1.Surface Permanent Magnet Synchronous Motor (SPMSM)

The permanent magnets are located on the surface of the rotor.

This layout results in a relatively simple motor structure and lower manufacturing process difficulty.

Since the permanent magnets are directly exposed to the air – gap magnetic field, the SPMSM can generate a relatively sinusoidal air – gap magnetic field, thus achieving good torque output characteristics.

In application scenarios where high requirements are placed on speed stability and the speed – regulation range is relatively narrow, such as small – sized fans and precision instrument drives, the SPMSM can give full play to its advantages and provide stable and reliable power output.

2.Interior Permanent Magnet Synchronous Motor (IPMSM)

The permanent magnets are embedded inside the rotor.

This design endows the motor with a unique reluctance torque.

The IPMSM can not only increase the torque density of the motor but also demonstrate better mechanical strength and field – weakening speed – expansion capabilities at high speeds.

In applications such as electric vehicles and high – speed machine tools that require a wide speed – regulation range and high – power output, the IPMSM becomes the first choice due to its excellent performance.

For example, when an electric vehicle is running at high speed, the IPMSM can maintain efficient operation through field – weakening control to meet the vehicle’s requirements for speed and range.

Back – EMF Waveform

Generally, they are designed to generate a sinusoidal back – electromotive force, that is, back – EMF.

What’s the use of this?

When this sinusoidal back – EMF is combined with a sinusoidal current control method, such as Field – Oriented Control (FOC), the motor can run very smoothly without jerking.

Why is this the case? Because the sinusoidal back – EMF waveform can make the phase current and the back – EMF cooperate more harmoniously when the motor is running, just like two people dancing in step.

In this way, the energy waste caused by non – sinusoidal waveforms, as well as the motor’s vibration and noise, can be reduced significantly.

Now look at brushless DC motors. Most of them generate a trapezoidal back – EMF.

Compared with permanent magnet motors, their control methods are different, and the characteristics during operation also vary a lot.

In areas with extremely high precision requirements, such as high – precision servo control, due to the sinusoidal back – EMF, permanent magnet motors can make the equipment position accurately and operate stably.

Therefore, permanent magnet motors are widely used in equipment such as CNC machine tools and industrial robots.

Rotor Inertia

Rotor inertia reflects the ability of the rotor to resist changes in rotational speed during rotation.

In permanent magnet motors, a smaller rotor inertia is conducive to achieving rapid acceleration and deceleration responses.

In application scenarios with extremely high requirements for dynamic response, such as robot joint drives and high – speed start – stop equipment on automated production lines, permanent magnet motors with a low rotor inertia can enable the equipment to change rotational speed rapidly and accurately execute various action commands.

For example, when an industrial robot performs rapid picking and placing operations, the low – inertia permanent magnet motor can ensure that the robotic arm starts, stops, and turns quickly, improving production efficiency and operation accuracy.

Cooling Methods

Common cooling methods for permanent magnet motors include air cooling, liquid cooling, and fan cooling.

The choice of cooling method directly affects the heat – dissipation effect and continuous operation capability of the motor.

1.Air Cooling

It has a simple structure and low cost, and is suitable for permanent magnet motors with relatively low power and less heat generation. Heat generated by the motor is dissipated into the surrounding environment through natural convection or forced air cooling.

For example, some permanent magnet motors in small household appliances can meet their heat – dissipation requirements through air cooling.

2.Liquid Cooling

It has a high heat – dissipation efficiency and can effectively remove a large amount of heat, making it suitable for high – power and high – heat – generating permanent magnet motors.

Usually, a coolant circulates inside the motor to absorb heat and transfer it to an external radiator.

In the permanent magnet drive motors of electric vehicles, the liquid – cooling system can ensure that the motor maintains an appropriate temperature during long – term high – load operation and sustains stable performance.

3.Fan Cooling

It combines the advantages of air cooling and forced heat dissipation.

By using a fan to enhance air flow, the heat – dissipation efficiency is improved.

It is often used in application scenarios with moderate power and higher heat – dissipation requirements than natural air cooling, such as some medium – sized industrial motors.

Sensor – based vs. Sensorless Control

1.Sensor – based Control

Position sensors (such as encoders and Hall sensors) are used to obtain real – time position and speed information of the rotor, thus enabling precise control of the motor.

This control method can still ensure high – precision control of the motor at zero speed or low speed.

In applications with extremely high requirements for position accuracy and speed stability, such as semiconductor manufacturing equipment and high – precision testing instruments, permanent magnet motors with sensor – based control can meet their strict control requirements and ensure the precise operation of the equipment.

2.Sensorless Control

It does not require additional position sensors but estimates the rotor position and speed by detecting electrical quantities of the motor (such as back – EMF and current).

This method reduces system cost and complexity and is suitable for application scenarios that are cost – sensitive and have relatively less stringent requirements for accuracy.

However, at zero – speed start – up or extremely low – speed operation, the accuracy and stability of sensorless control will face certain challenges.

For example, in the permanent magnet motor drive systems of some consumer electronics products, sensorless control can not only meet the basic performance requirements but also effectively control costs.

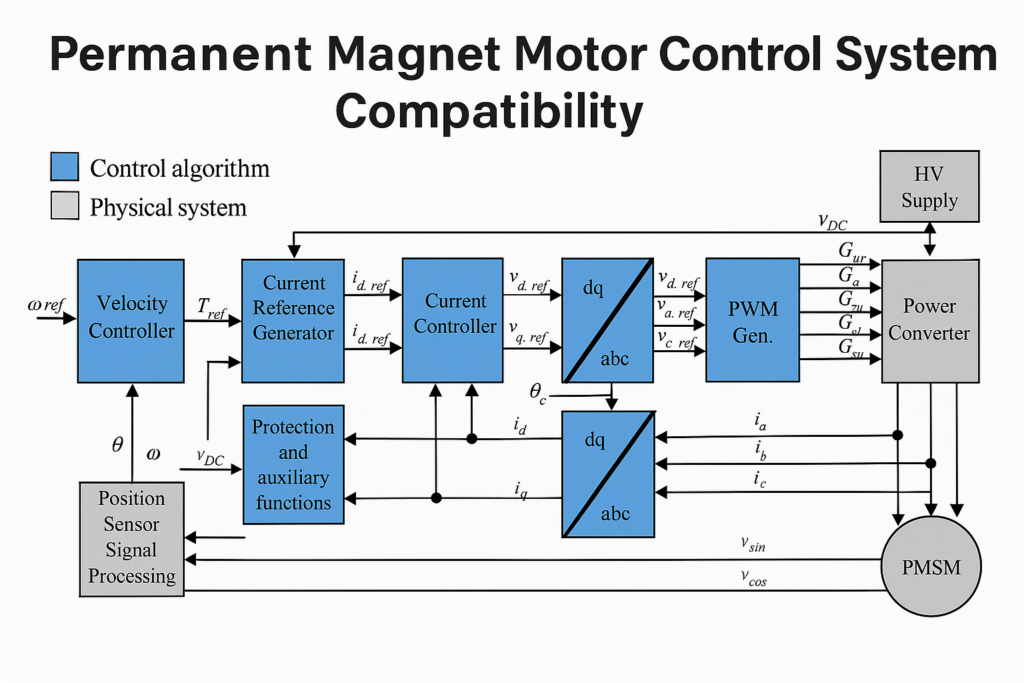

Control System Compatibility

Voltage Requirements

It is essential to ensure that the rated voltage of the motor matches that of the controller.

A mismatch in voltage can lead to various issues.

If the output voltage of the controller is higher than the rated voltage of the motor, it may damage the insulation of the motor windings, shorten the motor’s service life, and even cause short – circuit faults.

Conversely, if the output voltage of the controller is lower than the rated voltage of the motor, the motor will not be able to output its rated power, and problems such as unstable rotation speed and insufficient torque may occur, failing to meet the application requirements.

For example, in an industrial automation production line, the voltage matching between the motor and the controller is the foundation for ensuring the stable operation of the equipment.

Any slight voltage deviation may affect production efficiency and product quality.

Current Capacity

The controller must have sufficient capacity to supply both the continuous current and peak current required by the motor during operation.

The motor requires a large peak current instantaneously during startup, acceleration, and sudden load changes.

If the controller cannot provide sufficient peak current, the motor may not start properly or may experience stalling during operation.

During the continuous operation of the motor, the controller needs to stably supply continuous current to ensure the stable power output of the motor.

Take the permanent magnet drive motor of an electric vehicle as an example.

When the vehicle accelerates and climbs slopes, the motor needs a large amount of current to provide sufficient torque.

At this time, the controller must be able to meet this current demand; otherwise, it will affect the vehicle’s power performance.

Control Algorithm

To achieve the optimal performance of Permanent Magnet Synchronous Motors (PMSMs), the Field – Oriented Control (FOC) algorithm is typically used.

Therefore, the selected controller should support a robust and stable FOC algorithm.

The FOC algorithm decomposes the stator current of the motor into exciting current and torque current for independent control, thereby achieving precise control of the motor’s torque and magnetic flux, enabling the motor to operate efficiently under different working conditions.

An excellent FOC algorithm can not only improve the efficiency and dynamic response speed of the motor but also reduce torque ripple and enhance the smooth operation of the motor.

In high – performance industrial drive systems or the electric vehicle field, the requirements for the accuracy and stability of the FOC algorithm are extremely high.

Only in this way can the strict requirements for motor performance under complex working conditions be met.

Feedback Devices

If a sensored PMSM is used, it is necessary to ensure that the controller is compatible with the selected encoder or resolver type.

Encoders and resolvers are used to accurately measure the position and speed of the motor rotor, providing real – time feedback information to the controller.

The controller then adjusts its control strategy based on this feedback to achieve precise control of the motor.

Different types of encoders and resolvers have different output signal forms and electrical characteristics.

If the controller is not compatible with the feedback device, it will not be able to accurately obtain the operating status information of the motor, resulting in a decrease in control accuracy and the motor not operating as expected.

For example, in the servo system of a CNC machine tool, the high – precision feedback of the encoder and the precise cooperation of the controller are key factors to ensure the machining accuracy of the machine tool.

Communication Interfaces

It is necessary to consider how the motor and the controller will communicate with the overall system.

Common communication interfaces include CAN, EtherCAT, Modbus, etc.

The communication interface determines the data transmission method and protocol between the motor and controller and other devices (such as the host computer, PLC, etc.).

Selecting the appropriate communication interface can ensure the seamless integration of the motor control system with the entire system, enabling efficient data interaction and collaborative work.

For example, in a large – scale factory automation control system, through the CAN bus interface, the motor and controller can communicate with the central control system in real – time, upload the operating status information of the motor, and receive control commands from the central control system, thus realizing the automation and intelligence of the entire production process.

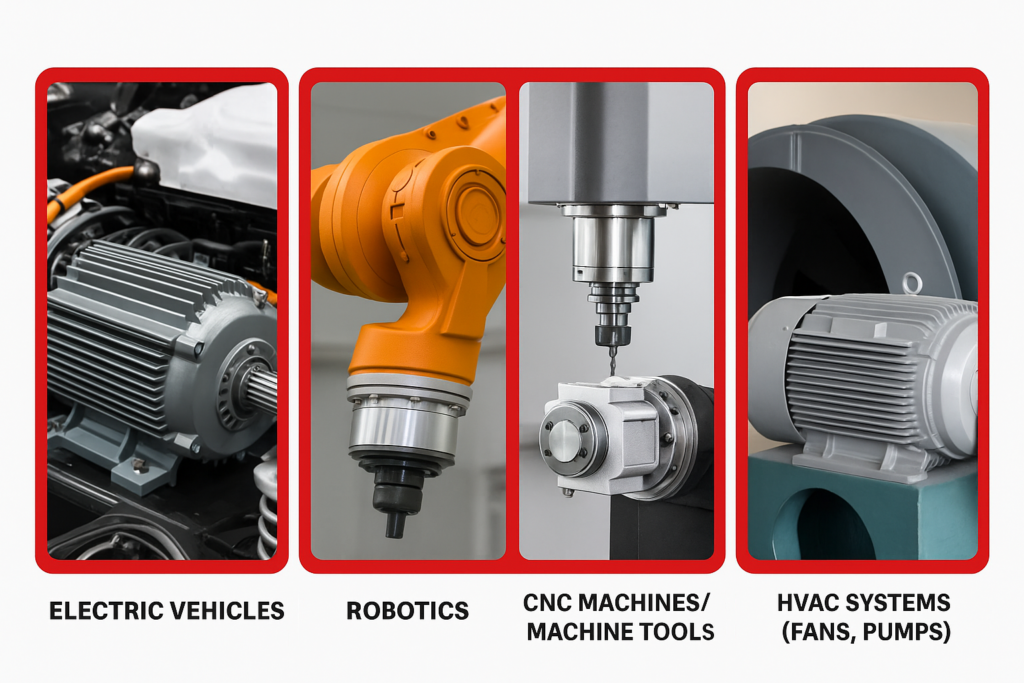

Application Examples

Electric Vehicles (EVs)

In the field of electric vehicles, permanent – magnet motors feature high power density, enabling them to operate with a relatively small volume and weight.

They also have high efficiency and can achieve precise torque control through the advanced Field – Oriented Control (FOC) algorithm.

For electric vehicle users, high power density meets the strict requirements of vehicles for range and space layout. Brands like Tesla use permanent – magnet synchronous motors, which improve the vehicle’s acceleration performance and top speed, making driving more exciting.

High efficiency reduces energy consumption, extends the vehicle’s range, and decreases the charging frequency, saving users’ time and energy as they don’t have to frequently look for charging stations.

Precise torque control brings a smooth driving experience.

Whether starting, accelerating, or decelerating, it can ensure stable and comfortable power output of the vehicle, making every trip enjoyable and enhancing the overall driving and riding experience.

Robotics

In robotic applications, permanent – magnet motors are characterized by low rotor inertia. They also feature quiet operation and high energy efficiency.

In the industrial sector, industrial robotic arms, with the help of the rapid start – stop and precise position – control capabilities of permanent magnet motors, can accurately carry out tasks such as picking, transporting, and assembling parts.

This greatly improves production efficiency and product quality, saving costs for enterprises and increasing their profits.

In home and service scenarios, service robots like home – cleaning robots and guide – dog robots operate quietly due to the use of permanent magnet motors, creating a quiet and comfortable environment for users and enhancing their experience.

At the same time, the high – efficiency and energy – saving features of permanent magnet motors extend the battery life, reducing the frequency of frequent charging.

This ensures that robots can work continuously and efficiently. Whether it’s for home cleaning or serving special – needs people, they can complete tasks more stably and effectively.

CNC Machines/Machine Tools

Permanent – magnet motors are specifically designed for CNC machines.

They have the characteristics of being adaptable to high – precision encoders and using advanced control algorithms.

Additionally, they possess stable performance at high speeds and the ability for rapid acceleration and deceleration.

They enable the machining accuracy to reach the micron or even nanometer level.

What does this mean? It means that the machined parts can strictly meet those extremely high requirements in terms of dimensions and shapes.

Take the machining of aerospace components as an example, where the requirements are extremely stringent.

The machine tools driven by permanent magnet motors can accurately perform operations such as milling, drilling, and grinding, manufacturing high – precision parts with complex shapes and fully meeting the high – quality standards of high – end manufacturing.

HVAC Systems (Fans, Pumps)

In Heating, Ventilation, Air – Conditioning (HVAC) systems, permanent – magnet motors are widely used in equipment such as fans and pumps.

The permanent – magnet motors for fans feature high efficiency, while those for pumps can precisely adjust the flow rate and pressure according to system requirements.

For users of HVAC systems, in large commercial buildings, fans driven by permanent – magnet motors can significantly save electricity costs during long – term operation, reducing the operational burden on enterprises.

In the application of pumps, such as in the water – circulation system of air – conditioners, water pumps driven by permanent – magnet motors can intelligently adjust the water flow rate according to environmental parameters like indoor and outdoor temperature and humidity.

This not only improves the overall energy efficiency of the air – conditioning system, reducing energy waste, but also greatly enhances user comfort.

Whether in hot summers or cold winters, users can enjoy a more comfortable indoor environment.

Washing Machines/Home Appliances

In the home appliance sector, permanent – magnet motors are applied to various appliances like washing machines.

They possess precise control capabilities, enabling adjustments according to different fabric materials and weights.

They also feature high energy – efficiency, and operate with low noise and minimal vibration.

For household users, in the case of washing machines, the precise control of permanent – magnet motors allows different fabric materials and weights of clothes to be washed in an appropriate way.

This not only ensures clean clothes but also prevents damage, thus extending the lifespan of clothes.

The high – energy – efficiency feature helps families cut down on electricity costs, aligning with the modern concept of environmentally – friendly and energy – saving living.

Moreover, the low – noise and low – vibration operation during the washing process makes it less noisy, creating a quiet and comfortable home environment for users.

In other home appliances such as refrigerator compressors and vacuum cleaner motors, permanent – magnet motors enhance product performance with their advantages.

This enables users to enjoy better refrigeration and freshness – keeping effects when using the refrigerator, and a more efficient and quiet cleaning experience when using the vacuum cleaner, comprehensively improving the user experience of home appliances.

Tip: Consult the Experts

Above, I’ve listed some practical applications of permanent – magnet motors.

However, in reality, the applications of permanent – magnet motors extend far beyond these examples.

Thanks to their advantages such as high efficiency, energy – saving, and precise control, permanent – magnet motors play a crucial role in many more fields, constantly fueling the development of various industries.

If you have more specific needs regarding permanent – magnet motors, whether it’s custom – made products with special specifications or specific performance requirements, please contact Shaoxing Jiayu Import & Export Co., Ltd. Our company specializes in the design and production of permanent – magnet motors.

We have an experienced professional team that can provide you with comprehensive solutions. Whether it’s product consultation or technical support, we’re always here for you.

We look forward to working with you to explore more possibilities of permanent – magnet motors.