Electric motor selection significantly impacts operational efficiency across industries.

Rare Earth Permanent Magnet Synchronous (PMS) Motors and Induction Motors (IMs) represent fundamentally different technologies with distinct torque behaviors.

This comparison examines their torque characteristics in practical terms, helping equipment manufacturers and plant managers make informed purchasing decisions without requiring deep technical expertise.

The analysis focuses on real-world performance metrics that directly affect productivity and operating costs.

What is Torque, and Why Does It Matter?

Torque serves as the rotational force determining a motor’s workload capacity. In industrial settings, torque characteristics influence everything from startup performance to long-term reliability.

Starting Torque: The First Push

Rare Earth PMS Motors generate immediate high torque through their permanent magnetic field, delivering full rotational force from zero RPM.

This instant response proves particularly valuable in applications requiring quick starts under load.

Induction Motors experience inherent slip between stator and rotor fields, creating a delayed torque buildup that may cause sluggish initial performance in precision applications.

Continuous Torque: Sustained Performance

The torque curve of PMS Motors remains remarkably flat across their operational speed range, maintaining consistent pulling power.

Induction Motors demonstrate a speed-dependent torque profile where available torque diminishes as rotational velocity increases, sometimes requiring oversizing to compensate for this characteristic.

Overload Torque: Handling Peak Demands

PMS Motors handle moderate overloads efficiently but face potential permanent magnet degradation under extreme conditions.

Induction Motors tolerate temporary overloads better due to their rugged construction and absence of sensitive magnetic components, making them suitable for applications with unpredictable load spikes.

And More:

- The Benefits of PMSM: Transforming Efficiency in Electric Motor Technology

- Overview of Permanent Magnet Synchronous Motors in China

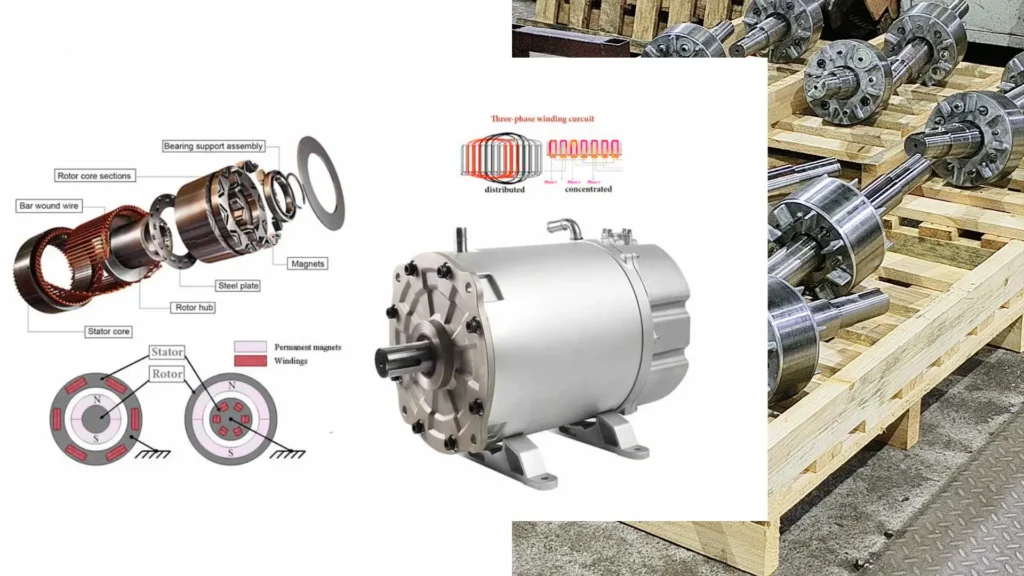

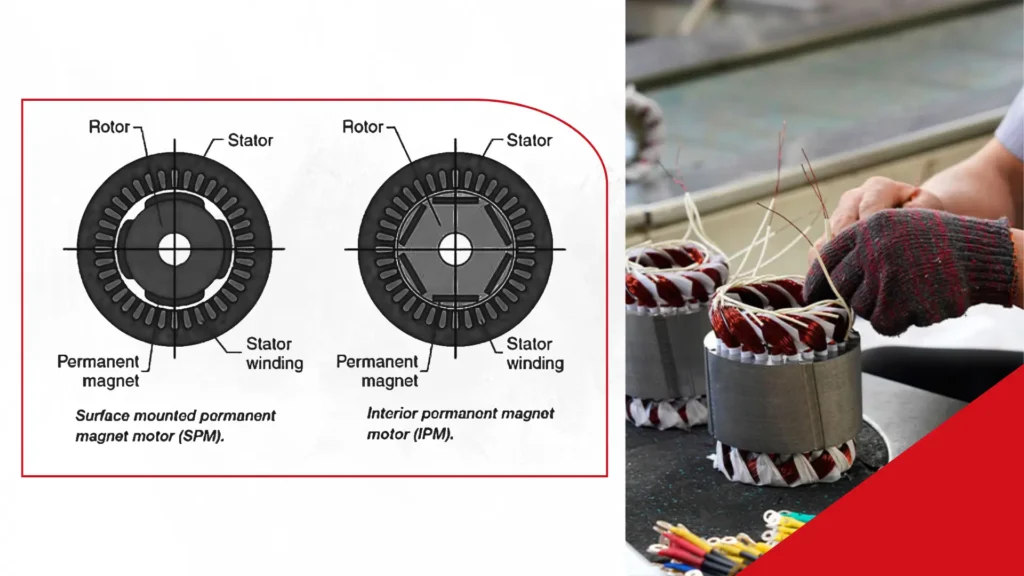

How Do PMS Motors Achieve Higher Torque Density?

Permanent Magnet Synchronous Motors deliver exceptional torque output relative to their physical size through advanced electromagnetic design principles.

Permanent Magnet Advantage

Neodymium-iron-boron (NdFeB) magnets generate magnetic flux densities exceeding 1.2 tesla, nearly triple the field strength achievable in induction motor rotors.

This intense magnetic field interacts directly with stator windings, eliminating the need for induced rotor currents.

The direct magnetic coupling converts over 97% of electrical input into usable torque, compared to 85-90% in induction motors.

Modern magnet configurations use Halbach array arrangements to further concentrate magnetic flux in the air gap.

Reduced Energy Losses

PMS motors eliminate rotor I²R losses entirely, reducing total energy losses by 15-20% compared to equivalent induction motors.

The absence of rotor current allows continuous operation at full torque without the thermal limitations affecting induction machines.

Advanced laminations with 0.2mm silicon steel cores minimize eddy current losses, while fractional-slot concentrated windings reduce copper losses by 30%.

Compact and Lightweight Design

The high torque density (up to 5 Nm/kg in premium designs) enables PMS motors to achieve equivalent power ratings in packages 25-40% smaller than induction motors.

This size advantage proves particularly valuable in electric vehicle drivetrains, where every kilogram saved improves range.

Integrated designs combine the rotor, bearings, and position sensors into single compact assemblies, further reducing overall system footprint.

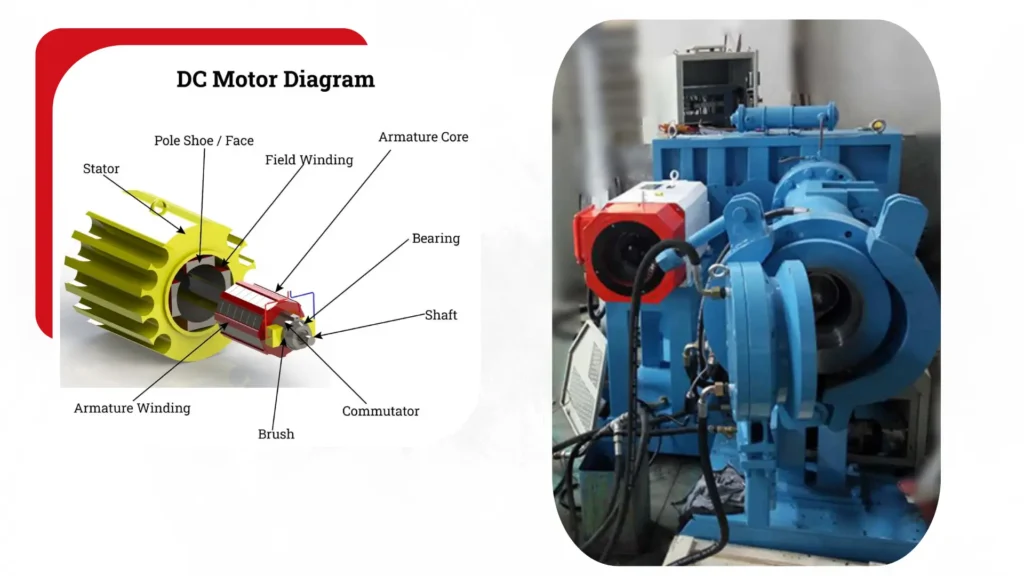

Why Do Induction Motors Have Lower Starting Torque?

The fundamental operating principles of induction motors create inherent limitations in initial torque production.

Slip-Dependent Torque

Induction motors require 3-5% slip between stator and rotor fields to generate torque, resulting in starting torque typically limited to 150-200% of rated torque.

The torque-slip curve shows maximum torque occurs at 10-20% slip, forcing a compromise between starting performance and running efficiency.

Deep-bar rotor designs improve starting torque to 250% but increase rotor losses during normal operation.

Higher Inrush Current

Locked rotor current in induction motors reaches 600-800% of full-load current, creating significant voltage drop in power systems.

This current surge persists until the motor reaches approximately 80% of synchronous speed.

Soft-start systems reduce inrush but further compromise starting torque, often limiting initial torque to just 50-75% of the motor’s capability.

Heat Build-Up in the Rotor

During acceleration, rotor currents generate substantial I²R heating, with rotor temperatures potentially reaching 150°C during frequent start-stop cycles.

Aluminum rotor conductors exhibit positive temperature coefficient resistance, increasing losses as temperature rises.

This thermal limitation often requires oversizing induction motors for applications with high starting inertia.

Also Read:

- Understanding Permanent Magnet Motors: Applications of AC and DC

- Cost Savings on Permanent Magnet Synchronous Motors

Which Motor Offers Better Speed-Torque Control?

Dynamic performance characteristics vary significantly between motor technologies.

PMS Motors: Precise and Responsive

Field-oriented control algorithms maintain torque accuracy within ±1% across the entire speed range.

The instantaneous torque response (typically <5ms) enables precise position control in servo applications.

Sensorless control techniques using high-frequency injection or back-EMF observation provide position feedback without physical encoders in many applications.

Induction Motors: Limited by Slip

Even with vector control, induction motors exhibit 10-20ms torque response times due to rotor time constants.

Slip compensation algorithms can maintain speed within ±0.5% of setpoint but require continuous adjustment.

The nonlinear torque-current relationship complicates precise torque control, especially at low speeds where magnetic saturation becomes significant.

Regenerative Braking Capability

PMS motors achieve 85-90% energy recovery efficiency during braking, with the generator mode producing up to 150% of rated torque for short durations.

Induction motors typically recover only 60-70% of braking energy due to higher rotor losses and the need to maintain excitation current.

The regeneration efficiency gap widens at lower speeds where induction motor slip losses dominate.

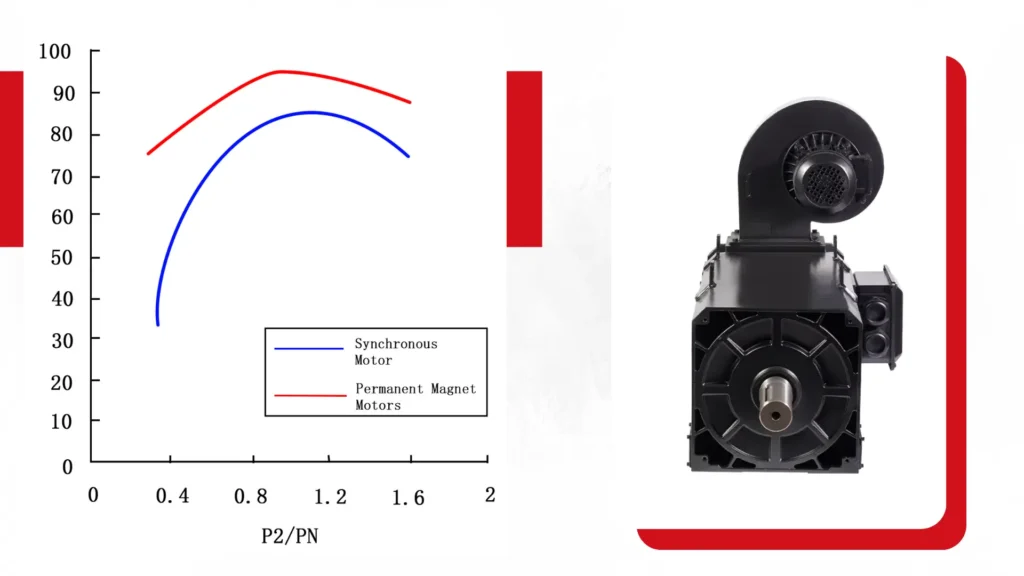

How Does Efficiency Affect Torque Performance?

Energy conversion efficiency directly correlates with torque production capability.

PMS Motors: 90-95% Efficiency

Premium PMS motors maintain efficiency above 90% from 25% load to 120% overload conditions.

The flat efficiency curve results from minimized losses in both rotor and stator components.

High-efficiency designs using copper rotor cages and segmented magnets achieve IE5 efficiency class ratings, the highest in international standards.

Induction Motors: 85-92% Efficiency

Standard induction motors reach peak efficiency at 75-100% load, with efficiency dropping sharply below 50% load.

Premium efficiency (IE3) designs reduce losses through optimized slot geometries and higher-grade materials, but still fall short of PMS motor performance.

The efficiency differential becomes most pronounced in smaller frame sizes (<10kW), where PMS motors may be 8-10 percentage points more efficient.

Impact on Continuous Duty Cycles

The superior thermal performance of PMS motors allows continuous operation at 110-120% of rated torque without derating.

Induction motors typically require derating to 80-85% of rated torque in continuous duty applications to prevent insulation degradation from prolonged overheating.

Liquid-cooled induction motor designs can mitigate this limitation but add complexity and cost.

And More:

- The Benefits of PMSM: Transforming Efficiency in Electric Motor Technology

- Advanced Features of High-Performance Permanent Magnet Motors from China

Which Motor Handles High Loads Better?

Load capability depends on both electromagnetic and thermal design factors.

PMS Motors: Superior in Dynamic Loads

The instantaneous torque capability of PMS motors handles rapid load changes effectively, with torque bandwidth exceeding 100Hz in servo applications.

The absence of rotor delay allows precise torque control during acceleration/deceleration cycles.

Overload capability typically reaches 200-300% of rated torque for short durations (1-2 minutes) without demagnetization risk in modern designs.

Induction Motors: Better for Steady Heavy Loads

The simple, robust construction of induction motors withstands continuous operation at 100-115% load indefinitely with proper cooling.

Cast aluminum or copper rotor cages handle thermal cycling better than permanent magnet assemblies.

Large frame induction motors (>100kW) particularly excel in constant-load industrial applications like compressors and crushers.

Overload Tolerance Comparison

Standard induction motors withstand 200-250% overload for 15-30 seconds without damage, while premium designs reach 300% overload capacity.

PMS motors face demagnetization risks above 250% overload but benefit from faster thermal time constants that allow quicker heat dissipation between overload events.

What Are the Cost and Maintenance Differences?

Lifecycle cost analysis must consider both acquisition and operational expenses.

PMS Motors: Higher Upfront Cost

The premium for PMS motors ranges from 1.5-2.5× the cost of equivalent induction motors, with larger size differentials in smaller power ratings.

Rare earth magnet prices fluctuate significantly, affecting total motor cost.

However, the total cost of ownership often favors PMS motors in applications with >4,000 operating hours annually due to energy savings.

Induction Motors: Lower Initial Price

Mature manufacturing processes keep induction motor costs competitive, particularly in medium-voltage ratings (>1kV).

Aluminum frame construction reduces material costs for standard duty applications.

The absence of position sensors and simpler power electronics further reduce system costs compared to PMS motor drives.

Maintenance Requirements

PMS motors require only periodic bearing lubrication (typically 20,000-40,000 hour intervals).

Induction motors need more frequent bearing attention (8,000-15,000 hours) due to higher operating temperatures.

Brushless designs eliminate commutator maintenance in both types, but induction motors may require occasional rotor bar inspections in high-vibration applications.

Also Read:

- Permanent Magnet Synchronous Motor Price Comparison

- Total Cost of Ownership (TCO): Calculating Long-Term Savings on PMS Motors

Which Motor is Best for Your Application?

Optimal motor selection depends on operational priorities and usage patterns.

Choose PMS Motors If You Need

Applications requiring precise motion control, high dynamic response, or maximum energy efficiency benefit most from PMS technology.

The technology excels in robotics, machine tools, and traction applications where torque density and controllability outweigh initial cost considerations.

Choose Induction Motors If You Need

Cost-driven applications with stable loads and infrequent speed changes remain ideal for induction motors.

Their proven reliability and lower maintenance requirements make them preferable for pumps, fans, and conveyors in industrial settings.

Hybrid Solutions

Some advanced systems combine both technologies strategically. A common configuration uses PMS motors for positioning and acceleration phases, with induction motors handling steady-state operation.

This approach balances performance and cost in applications like elevators and large compressors.

Conclusion

The torque characteristics of Rare Earth PMS Motors and Induction Motors cater to different operational priorities.

PMS technology delivers superior efficiency, dynamic response, and power density, while Induction Motors offer cost advantages and proven reliability in stable load conditions.

Understanding these fundamental differences allows buyers to match motor technology to their specific operational requirements and financial parameters.

For applications where energy costs dominate lifecycle expenses or where performance demands exceed Induction Motor capabilities, PMS Motors typically provide the better long-term solution despite higher initial investment.