Rare earth permanent magnet synchronous (PMS) motors are gaining attention for their superior efficiency and performance.

But with higher upfront costs than conventional motors, many businesses wonder: Are they truly worth the investment?

This article breaks down the key factors—efficiency, lifespan, maintenance, and long-term savings—to help you decide if rare earth PMS motors are the right choice for your operations.

What Makes Rare Earth PMS Motors Different?

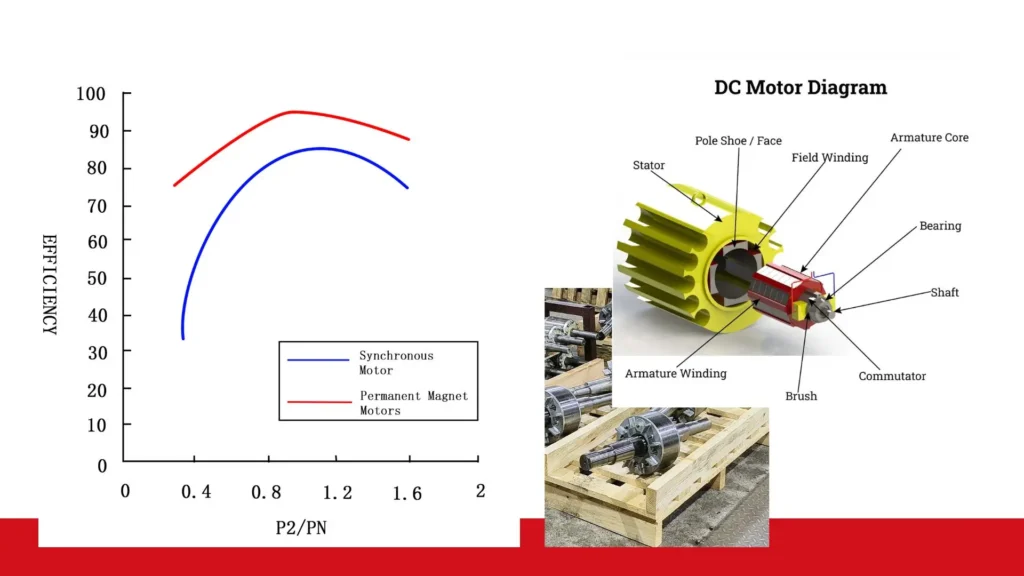

Higher Energy Efficiency

Rare earth PMS motors stand out for their exceptional energy-saving capabilities.

Unlike conventional motors that lose significant power through heat and friction, these advanced motors convert electrical energy into mechanical motion with remarkable efficiency.

This translates directly to lower electricity bills, with some applications seeing energy savings of 20-30% compared to standard induction motors.

For businesses running multiple motors continuously, this efficiency advantage can result in substantial cost reductions over time.

Stronger Magnetic Performance

The secret behind these motors’ superior performance lies in their rare earth permanent magnets, typically made from neodymium or samarium-cobalt alloys.

These powerful magnets create a consistent magnetic field that doesn’t weaken over time, enabling the motor to deliver strong torque even at very low rotational speeds.

This characteristic makes them perfect for applications requiring precise speed control and immediate responsiveness, such as in medical equipment or high-precision manufacturing tools.

Compact and Lightweight Design

Engineers appreciate how rare earth PMS motors pack impressive power into surprisingly small packages.

A motor with equivalent power output to a traditional induction motor might weigh half as much and occupy significantly less space.

This compact design opens up new possibilities for equipment manufacturers, allowing for more streamlined machinery designs and easier installation in space-constrained environments.

The weight savings are particularly valuable in mobile applications where every kilogram matters.

Also Read:

- Rare Earth PMS Motors vs. Switched Reluctance Motors: Which Wins on Efficiency?

- Revolutionizing Wind Turbines: Rare Earth PMS Motors in Renewable Energy

How Do They Compare to Traditional Motors in Performance?

Better Speed Control

Precision is where rare earth PMS motors truly excel. They maintain consistent speeds regardless of load variations, responding instantly to control inputs with minimal lag.

This level of control is unattainable with conventional motors and is particularly valuable in applications like semiconductor manufacturing equipment or electric vehicle drivetrains, where exact speed regulation directly impacts product quality and system performance.

Higher Power Density

The power-to-weight ratio of rare earth PMS motors is unmatched in the electric motor world.

They can deliver the same mechanical power as larger induction motors while occupying less than half the space.

This high power density enables innovative designs in everything from drones to industrial robots, where maximizing performance while minimizing size and weight is critical.

The aerospace industry particularly values this characteristic for applications like aircraft actuators and flight control systems.

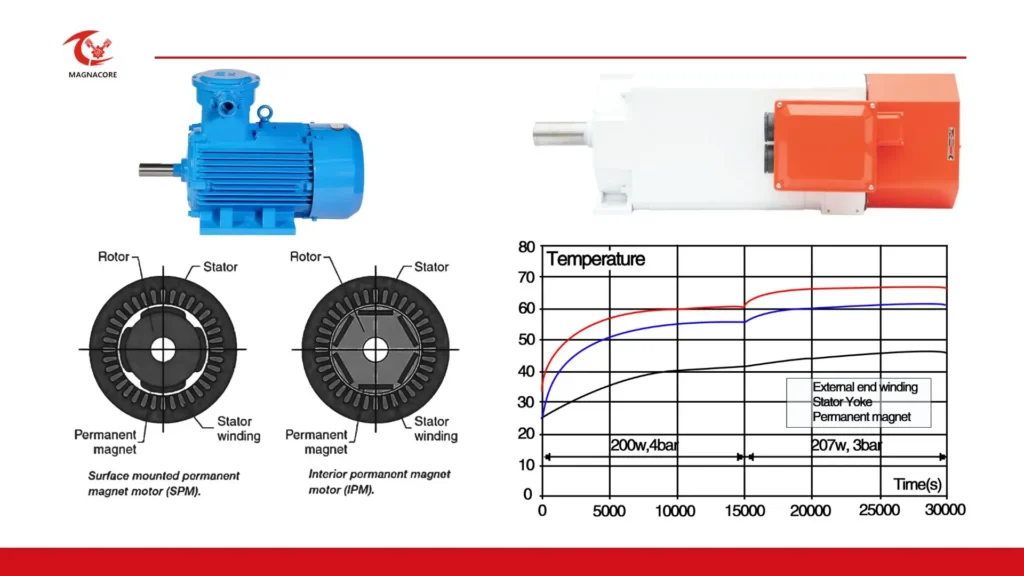

Lower Heat Generation

Traditional motors often waste energy as heat, requiring additional cooling systems that add cost and complexity.

Rare earth PMS motors run noticeably cooler thanks to their efficient design and permanent magnet technology.

This reduced heat output means longer bearing life, less thermal stress on components, and often the elimination of external cooling fans.

The result is a motor that runs more reliably for longer periods with less maintenance.

What Are the Upfront Costs?

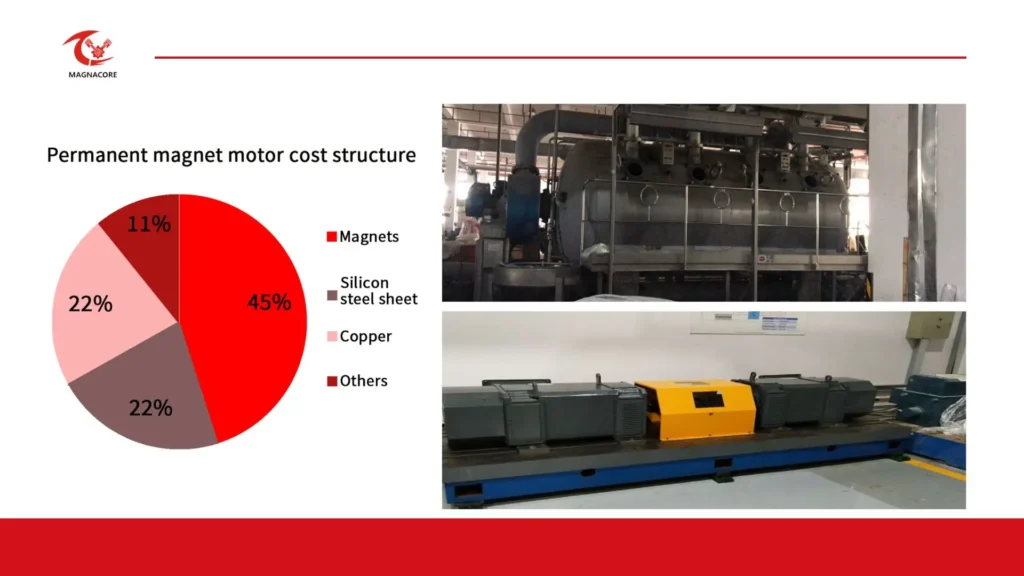

Higher Initial Purchase Price

The premium pricing of rare earth PMS motors reflects their advanced technology and material composition.

These motors typically cost 20-50% more than comparable induction motors, with the price difference stemming from expensive rare earth magnets and more sophisticated manufacturing processes.

The permanent magnets alone can account for a significant portion of the total cost, as they require specialized materials like neodymium that are subject to market price fluctuations.

However, this initial investment should be weighed against the operational savings over the motor’s lifetime.

Potential Retrofitting Expenses

Adopting PMS motor technology may involve additional costs beyond the motor itself.

Many existing systems were designed for traditional induction motors and may need upgraded variable frequency drives (VFDs) or control systems to properly manage the PMS motor’s characteristics.

In some cases, mechanical modifications might be necessary to accommodate the different physical dimensions or mounting requirements.

These supplementary investments should be factored into the total cost of ownership calculations when considering a switch to PMS technology.

Longer ROI Period

The return on investment timeline for rare earth PMS motors typically ranges from 2-5 years, depending on usage patterns and energy costs.

While the energy savings are significant, the higher initial outlay means it takes longer to recoup the additional expenditure compared to conventional motors.

Operations with continuous, high-load applications will see faster payback periods, while intermittent-use scenarios may require more patience before realizing the full financial benefits.

Proper lifecycle cost analysis helps determine if the extended ROI period makes business sense for specific applications.

And More:

- Total Cost of Ownership (TCO): Calculating Long-Term Savings on PMS Motors

- Cost Savings on Permanent Magnet Synchronous Motors

Where Do the Long-Term Savings Come From?

Reduced Energy Bills

The superior efficiency of rare earth PMS motors delivers ongoing savings that accumulate substantially over time.

In continuous operation scenarios, the energy savings alone can total tens of thousands of dollars over a motor’s lifespan.

Facilities with multiple motors or high electricity rates see particularly dramatic cost reductions.

Many users find their cumulative energy savings eventually exceed the motor’s entire purchase price, making the initial premium a wise investment rather than an expense.

Minimal Maintenance Needs

PMS motors eliminate many common failure points found in traditional motors. The absence of brushes, commutators, or slip rings removes components that typically wear out and require regular replacement.

This design advantage translates to fewer service interruptions, lower maintenance labor costs, and reduced inventory of spare parts.

The simplified mechanical structure also means fewer unexpected breakdowns, contributing to more predictable operating costs and improved production reliability.

Extended Operational Lifespan

Constructed with premium materials and operating under less thermal and mechanical stress, rare earth PMS motors often outlast conventional alternatives by years.

The permanent magnets maintain their strength indefinitely under normal operating conditions, and the overall robust construction withstands demanding environments.

This longevity means fewer motor replacements over time, reducing both capital expenditures and the downtime associated with equipment changeouts.

The extended service life makes these motors particularly attractive for hard-to-access or mission-critical applications where replacement is difficult or costly.

Are There Hidden Costs to Consider?

Rare Earth Material Price Volatility

The global rare earth market experiences periodic price swings that directly affect PMS motor costs.

Geopolitical factors and mining regulations in primary producing countries can create supply uncertainties.

While recycling programs for rare earth magnets are expanding, current recovery rates still can’t fully stabilize material costs.

Buyers should consider these potential price fluctuations when budgeting for PMS motor projects, especially for large-scale deployments where material costs represent a significant portion of the total investment.

Specialized Repair Requirements

Maintenance of rare earth PMS motors demands specific technical knowledge that not all service providers possess.

The unique characteristics of permanent magnet systems require different diagnostic approaches and repair techniques compared to conventional motors.

This specialization often translates to higher service charges and potentially longer wait times for qualified technicians.

Facilities in remote locations may face additional challenges in accessing timely PMS motor repair services, making in-house training or service contracts worthwhile considerations.

Compatibility with Existing Systems

Retrofitting older equipment with PMS motors sometimes reveals unexpected integration challenges.

Control systems designed for induction motors may lack the necessary programming flexibility for optimal PMS motor operation.

Mechanical interfaces, mounting configurations, or cooling requirements might need adaptation.

These compatibility issues can add unanticipated engineering and modification costs to what initially appears to be a straightforward motor replacement project.

A thorough system assessment before purchase helps identify and budget for these potential integration expenses.

Also Read:

- Permanent Magnet Synchronous Motor Price Comparison

- A Comprehensive Guide to Permanent Magnet Synchronous Motor Wholesale in China

Which Industries Benefit the Most?

Electric Vehicles (EVs) and Hybrids

The automotive industry’s shift toward electrification heavily relies on rare earth PMS motors.

Their combination of high power density and efficiency enables longer vehicle range without increasing battery size.

The instant torque delivery characteristic of PMS motors provides the responsive acceleration drivers expect, while their compact dimensions allow for more flexible vehicle packaging.

These advantages explain why most premium EVs and hybrid systems now standardize on PMS motor technology.

Industrial Automation

Modern automated manufacturing systems demand the precision and reliability that PMS motors deliver.

In robotic applications, their exact speed control enables repeatable positioning accuracy measured in fractions of a millimeter.

CNC machinery benefits from the consistent torque across all operating speeds, ensuring uniform cutting quality.

The maintenance-free operation of PMS motors also reduces downtime in continuous production environments where equipment availability directly impacts output and profitability.

Renewable Energy Systems

Wind turbine generators using PMS technology achieve higher energy conversion efficiency across a wider range of wind speeds.

Their compact size allows for direct-drive configurations that eliminate maintenance-heavy gearboxes.

Solar tracking systems utilize the motors’ precise positioning capability to optimize panel alignment throughout the day.

In both applications, the reliability and efficiency of PMS motors contribute directly to improved energy harvest and reduced operational costs over the system lifetime.

What Does the Future Hold for PMS Motors?

Advances in Magnet Recycling

Cutting-edge recycling technologies are transforming how we obtain rare earth materials for PMS motors.

Innovative processes can now recover over 95% of rare earth elements from used motors and electronic waste, creating a more sustainable supply chain.

These closed-loop systems not only reduce environmental impact but also help stabilize material costs by decreasing dependence on primary mining operations.

Several major manufacturers have already implemented take-back programs, ensuring valuable magnets get a second life in new high-efficiency motors.

Improved Manufacturing Efficiency

Production innovations are making PMS motors more affordable than ever before.

Automated assembly lines and optimized magnet placement techniques have significantly reduced labor costs. Simultaneously, material science breakthroughs allow for thinner magnet designs without sacrificing performance.

These manufacturing improvements, combined with increasing production volumes, are steadily closing the price gap between PMS motors and conventional alternatives – making the technology accessible to broader market segments.

Growing Adoption in Emerging Markets

Developing economies are recognizing PMS motors as key components in their industrial modernization and energy conservation strategies.

Government initiatives promoting energy-efficient equipment often include PMS motors in their recommended technology lists.

The motors’ superior performance characteristics align perfectly with the needs of rapidly industrializing nations looking to leapfrog older, less efficient technologies.

This global expansion is creating new market opportunities while further driving down costs through economies of scale.

Conclusion

Rare earth PMS motors represent a smart investment for forward-thinking businesses across multiple industries.

While the initial costs may be higher, their superior efficiency, reliability, and long-term savings potential make them a compelling choice.

As technology advances address current limitations around material costs and availability, these high-performance motors are poised to become the new standard in electric motion systems.

Companies adopting PMS technology now position themselves for both immediate operational benefits and future competitive advantages.