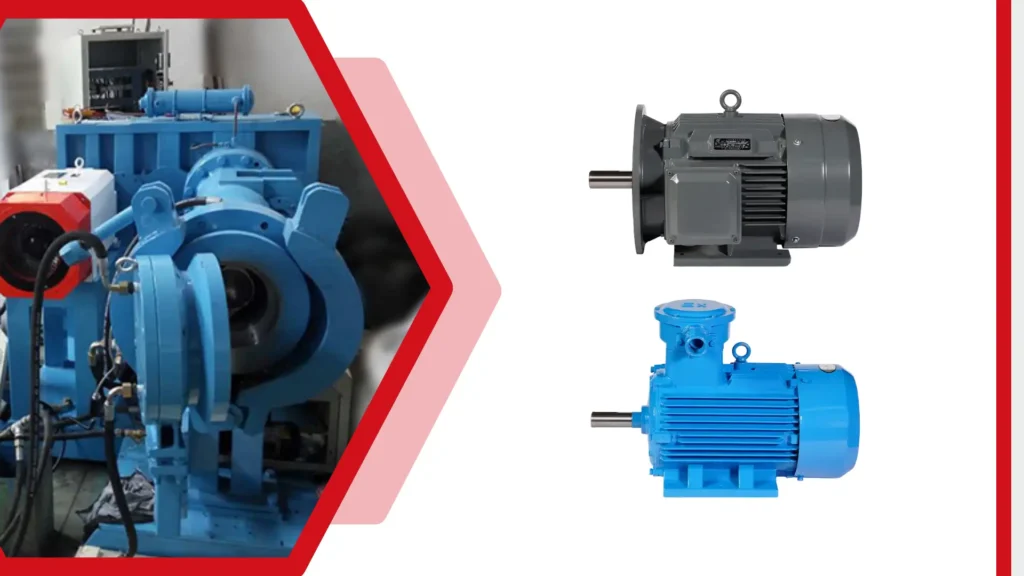

A Permanent Magnet Synchronous Motor (PMSM) is an advanced type of electric motor characterized by its use of permanent magnets embedded in the rotor.

This design allows the motor to operate with high efficiency, as it synchronizes the rotor’s movement with the frequency of the electrical supply.

Unlike traditional motors that rely on induced currents, PMSMs capitalize on the magnetic fields created by permanent magnets, resulting in superior performance in various applications.

Custom PMSM motors are tailored to meet specific performance and operational needs that standard motors may not address.

These features can include optimized dimensions for space constraints, unique power ratings that match precise load requirements, and specialized control systems that enhance responsiveness.

By customizing these motors, manufacturers can ensure that they operate at peak efficiency in their intended applications, providing solutions that are not only effective but also innovative.

Additionally, their high efficiency and compact design make them ideal for robotics and various consumer products, where performance and space are critical.

Why Choose a Custom PMSM Motor?

Tailored Solutions for Unique Needs

One of the standout advantages of custom PMSM motors is their ability to be tailored to address the unique challenges of specific projects.

Whether a company requires a motor with a unique size, special mounting configurations, or specific performance characteristics, a custom solution can provide the necessary adjustments.

This level of customization ensures that the motor aligns perfectly with the application’s requirements, leading to optimal operation.

Benefits of Customization

Customization enables the integration of cutting-edge technology and innovative designs that can significantly enhance a motor’s performance.

This includes improvements in energy efficiency, reduced operational costs, and increased durability.

Businesses that invest in custom PMSM motors often experience long-term benefits, including lower maintenance costs and higher production efficiency, which can greatly enhance overall competitiveness in their respective markets.

Enhanced Efficiency and Performance

PMSM motors are renowned for their high efficiency, converting a larger portion of electrical energy into mechanical energy compared to standard motors.

This efficiency translates to reduced energy consumption, which is increasingly important in today’s environmentally conscious world.

Moreover, enhanced performance characteristics, such as higher torque and faster response times, make custom PMSM motors ideal for demanding applications, ensuring they deliver superior results.

How Does a PMSM Motor Work?

Basic Operating Principles

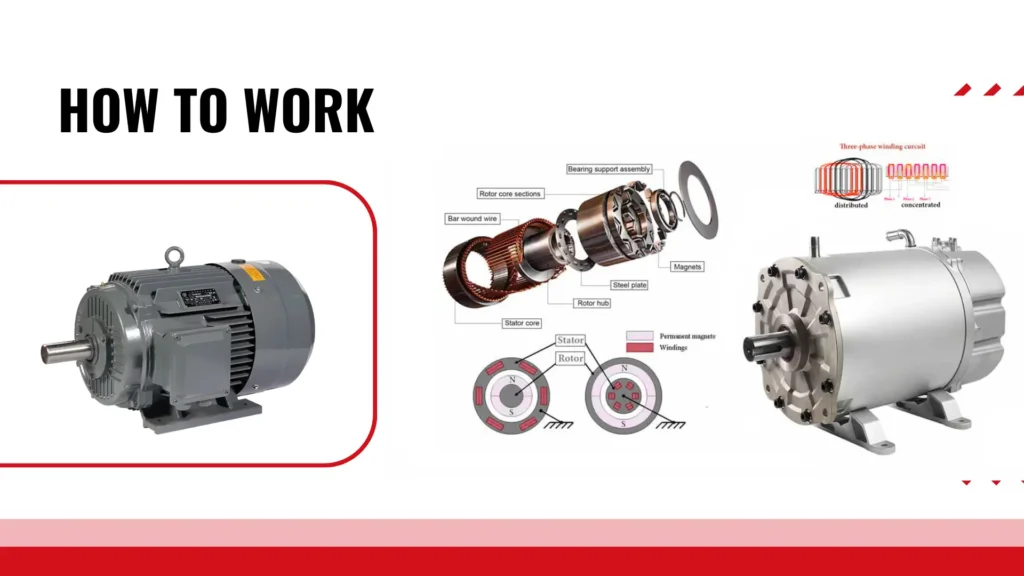

PMSM motors operate based on electromagnetic induction, where the magnetic field generated by the stator interacts with the rotor’s magnetic field.

This interaction creates rotational motion, allowing the motor to perform work.

The synchronization of the rotor speed with the electrical supply frequency is crucial; it allows for precise control over the motor’s operation, which is essential in applications requiring accurate speed and torque management.

Components of the Motor

The primary components of a PMSM include the rotor, which houses the permanent magnets; the stator, which contains the windings; and the control system that manages the motor’s operation.

Each component plays a vital role in ensuring the motor operates efficiently and effectively.

The quality of these components significantly influences the motor’s overall performance, making it crucial for manufacturers to use high-quality materials and advanced engineering techniques.

Advantages Over Traditional Motors

PMSM motors offer numerous advantages over conventional induction motors, such as higher torque density, improved efficiency, and a smaller footprint.

These motors also provide smoother operation with less noise, which is particularly beneficial in applications where sound levels matter, such as in residential appliances or medical equipment.

The reduced size and weight of PMSM motors allow for more flexible designs and easier integration into various systems.

What Are the RPM Ranges of Custom PMSM Motors?

Understanding RPM and Its Importance

Revolutions Per Minute (RPM) is a key measurement that indicates how many times the rotor completes a full rotation in one minute.

This metric is crucial because it directly impacts the motor’s performance in specific applications.

Selecting the correct RPM for your motor is essential to ensure that it meets the operational demands of your project, providing the right balance of speed and torque.

Differences Between 4000 RPM and 12000 RPM

Custom PMSM motors can be designed to operate across a range of RPMs.

A motor rated at 4000 RPM is typically suited for applications requiring moderate speed and torque, such as conveyor systems in manufacturing.

In contrast, a motor rated at 12000 RPM is ideal for high-speed applications, such as precision tools, where rapid response and high performance are critical.

Understanding these differences helps businesses select the appropriate motor for their specific use cases.

Selecting the Right RPM for Your Application

Choosing the right RPM is vital for optimal motor performance.

Factors to consider include the load requirements, the type of application, and the desired efficiency.

Consulting with motor specialists can provide valuable insights into RPM selection, ensuring that the motor’s capabilities align with the application’s demands.

This careful selection process can lead to enhanced performance and efficiency in the long run.

Who Can Benefit from Custom PMSM Motors?

Industries Requiring High Precision

Industries such as aerospace, medical technology, and high-end manufacturing often demand high-precision components.

Custom PMSM motors can be engineered to meet these stringent accuracy and performance specifications, ensuring reliable operation in critical applications.

The ability to fine-tune various aspects of the motor’s design makes it an invaluable asset for these sectors.

Applications in Robotics and Automation

In the rapidly evolving fields of robotics and automation, precise control and responsiveness are essential.

Custom PMSM motors can be designed to offer the high torque and quick response times necessary for robotic arms, automated assembly lines, and other advanced systems.

Their reliability and efficiency make them ideal for applications where performance can significantly impact productivity and operational success.

Benefits for Electric Vehicles

Electric vehicles (EVs) increasingly rely on custom PMSM motors for their propulsion systems.

These motors provide not only high efficiency and performance but also contribute to the overall sustainability of EV designs.

Custom solutions enable manufacturers to optimize motor integration into vehicle systems, enhancing performance and extending battery life, which is crucial for the consumer market.

Where to Source Quality Custom PMSM Motors in China?

Key Manufacturers and Suppliers

China is home to numerous manufacturers specializing in custom PMSM motors.

Identifying and partnering with reputable suppliers is essential to ensure you receive high-quality products tailored to your specific needs.

Researching manufacturers and seeking recommendations can help you find the right partner for your project.

Factors to Consider When Choosing a Supplier

When selecting a supplier for custom PMSM motors, consider factors such as their production capabilities, quality control processes, and customer service.

A reliable supplier will not only provide quality products but will also work closely with you to ensure that your requirements are fully understood and met.

Establishing a strong partnership can lead to successful project outcomes.

Understanding Quality Standards and Certifications

Quality standards and certifications play a crucial role in ensuring that PMSM motors meet industry regulations and performance expectations.

Look for suppliers that adhere to international standards, such as ISO certifications, as this indicates a commitment to quality and reliability.

Ensuring that your supplier meets these standards can provide confidence in the performance and longevity of the motors.

How to Ensure the Quality of Your Custom PMSM Motor?

Importance of Quality Control

Implementing rigorous quality control measures throughout the manufacturing process of custom PMSM motors is essential.

Quality checks at various stages of production help identify and rectify potential issues before they become significant problems.

This proactive approach ensures that the final product meets the required specifications and performs reliably in its intended application.

Recommended Testing Procedures

Testing procedures for PMSM motors should encompass a variety of assessments, including performance evaluations under different loads, efficiency testing, and safety checks.

Comprehensive testing ensures that the motor will operate reliably and efficiently in its intended environment.

Adhering to established testing protocols can also provide valuable data to inform future designs and improvements.

Certifications to Look For

When sourcing custom PMSM motors, it is important to look for certifications that signify compliance with industry standards.

Certifications such as ISO 9001 for quality management, CE marking for safety, and UL certification for electrical safety indicate that the manufacturer adheres to recognized quality and safety standards.

These certifications provide assurance regarding the reliability and performance of the motors.

What Are the Cost Factors for Custom PMSM Motors?

Breakdown of Costs Involved

The cost of a custom PMSM motor can vary widely based on several factors, including design complexity, materials used, and production volume.

Understanding the breakdown of these costs can help businesses budget effectively for their projects.

Key cost components may include raw materials, labor, engineering design, and testing.

Value for Money vs. Price

While the upfront price of a custom PMSM motor may be higher than that of standard options, it is crucial to evaluate the long-term value.

Custom motors often deliver greater efficiency, durability, and performance, leading to significant cost savings over time.

Businesses should assess the total cost of ownership rather than solely focusing on the initial purchase price.

Long-term Investment Considerations

Investing in a custom PMSM motor can be a strategic decision that pays off in the long run.

By enhancing operational efficiency and reducing maintenance costs, these motors can contribute to a company’s profitability and sustainability goals.

Businesses that prioritize quality and performance in their motor selection are likely to see substantial returns on their investment over time.

Conclusion

In a rapidly evolving technological landscape, the demand for efficient and high-performance motors like custom Permanent Magnet Synchronous Motors (PMSMs) is greater than ever.

These motors not only provide tailored solutions for specific applications but also enhance operational efficiency and reduce long-term costs.

By understanding the unique features, advantages, and applications of custom PMSM motors, businesses can make informed decisions that align with their specific needs.

As industries across the globe increasingly prioritize sustainability and performance, investing in custom PMSM motors represents a strategic choice.

With their ability to deliver high torque, precise speed control, and energy efficiency, these motors are ideal for a wide range of applications—from electric vehicles to advanced robotics.

Sourcing quality custom PMSM motors from reputable suppliers in China ensures that businesses receive products that meet stringent quality standards and performance expectations.