Permanent magnet motors operate under the principle of high-efficiency utilization of a permanent magnet generation mechanism.

Through the use of magnetic systems instead of electromagnets, it is possible to convert energy in a more efficient manner which results into improved performance, low energy consumption, and reduced operating costs.

High-efficiency permanent magnet motors are found in various industrial areas: from manufacturing to automotive to HVAC to renewable energy.

These motors drive applications in electric vehicles, industrial machinery, pumps, fans, and many others.

These are increasingly being adapted, along with modern changes, for more efficient and effective advancements, made to suit modern technologies.

Understanding Support and Maintenance

Significance of Consistent Maintenance

Maintenance is important to the life span and functioning of a high-efficiency PMM.

An efficient routine ensures that it will not breakdown at any point of time, runs smoothly, and time wastage in the shutdown is avoided.

Additionally, a regular maintenance schedule improves efficiency in the organization’s motors while keeping the return on investment at the maximum level.

Widely Known Maintenance Practices

One of the widely known maintenance practices-includes aligning the motor with load, performing measures before performance checks, testing on a speed-trial basis, subjecting the motor to routine inspections and basic items such as cleaning, lubrication, and performance tests.

Resolving Problem

Proactively diagnosing and troubleshooting saves one’s business a lot of time and money.

Generally, PMMs report abnormal noise, overhead heating, or less output.

All these symptoms should be well understood, and a systematic procedure for finding those faults prescribed where it may involve examination of electrical connections, visualizing mechanical parts, and applying diagnostics tools.

And More:

Essential Guide to High Efficiency Permanent Magnet Motor Specifications

Choosing the Right Support Services

Support Services Available Specific

They offer some categories of support-coefficient in-service high-efficiency PMMs, with some as routine maintenance contracts and emergency repair services.

Some companies bundle such installation, training, and associated ongoing technical support services.

Different types of services available determine the ideal selection of support requirement to be acquired by businesses.

Criteria for Choosing a Service Provider

Amongst the issues to consider, one is most important, that is, the experience of the service provider in PMMs, what is the response time to emergency calls, and.other related services to PMM.

Customer reviews, and case studies would also help you find out whether the service provider is reliable and experienced.

Advantages of Local Support

Some of the advantages of local support are a faster response time and a tailored approach that takes regional contingencies into consideration.

Local suppliers are also well versed with area-specific challenges and therefore provide tailored advice and support that makes operation more efficient.

Insights into the Chinese Market

Reasons for Sourcing from China

In the top notch producing manufacturer of high-efficiency PMMs then China,

That makes it available at competitive prices for a larger selection of products. With such vast scale production costs are expected to be lower and so customers will be paying less for their parts.

In a way, this explains how advanced manufacturing technologies also contribute to the high quality of the motor production.

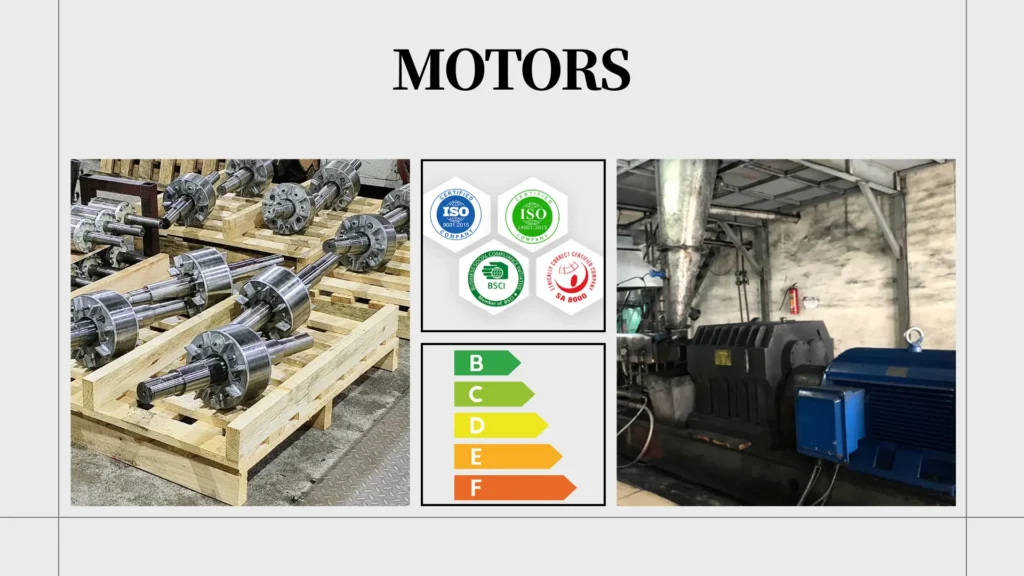

Quality Control Practices

Quality control practices applied in Chinese manufacturers are stringently adhered to meet the international standards expected of their products.

Factory systems usually ISO certify and then highly intensive tests formed to produce top qualities.

Knowledge of such practices would then enhance customer confidence in the sourcing motor from China.

Cost-Effectiveness and Efficiency

Sourcing super-efficient PM motors from China can save a great deal without compromising quality.

The common denominator in these low prices is the labor budget plus an up-front investment in the newest production technology.

Another important feature of these motors is that they usually save energy when run, which adds to their cost effectiveness over the long haul.

Cost-Benefit Analysis of High-Efficiency Motors

Capital and Long-lasting Savings

High-efficiency permanent magnet motors (PMM) typically need more upfront when compared to similar traditional motors.

However, this is always compensated by the much-anticipated savings from energy bills over time.

Thus, a much lower energy cost will make PMMs attractively cheaper in the course of time because operational costs will be reduced.

Therefore, the companies which will undertake such an analysis will be able to take measures considering both the initial and running expenses, thereby making informed decisions that will impact positively on their balance sheets.

ROI Calculation

For organizations, it is important to compute the return of investment (ROI) when it comes to high-efficiency motors.

ROI is computable by comparing total costs (purchase, installation, and maintenance) against expected energy cost savings and enhanced productivity.

Properly structured ROI analysis would show payback time and overall monetary benefits, thus justifying the cause for investment by decision-makers.

Most companies discover the ROI possible in a few years since PMMs are mostly efficient.

Incentives and Rebates for Energy-Efficient Solutions

Governments and their branches and agencies, or even companies, offer incentives and rebates to companies that adopt energy-efficient technologies such as high-efficiency PMMs.

With these incentives, the initial costs may actually cut the enterprise’s investments enough to benefit the switching process.

Organizations thus have to look at the available programs and familiarize themselves with all bonuses and grants they are entitled to receive, whereby these could march towards ensuring overall cost effectiveness.

And More:

High-Performance Permanent Magnet Motors Made in China for Commercial Applications

Maintenance Tools and Technologies

Availability of Proper Tools for Maintenance

Certain tools and equipment are ideal for a specific and correct use in the maintenance of high-efficiency PMMs.

Vibration analysis devices, thermal imaging cameras, and torque wrenches are example essential tools deployed, which can even diagnose problems early.

These are very solid tools in assuring efficient routine maintenance checks and repairs personnel in the manner proper, which ensures the life of the motors while improving the performance levels.

Performance Monitoring Software Solutions

Software technology has come up with unique programs today that provide observation and monitoring for the effects of maximum efficiency in PMMs.

These systems can also provide real-time data on motor activities how they are performing, or under-performing, and predict serious problems before they could actually happen and develop.

Through such technology, overheads are eliminated, and optimizing operation efficiency minimizes downtimes from the proactive maintenance strategies imposed.

Importance of Data Analytics in Maintenance

In high-efficiency motors, data analytics is very critical in maintenance.

Performance data helps businesses to understand irregularities or trends that may indicate internal problems.

Companies are moving from purely reactive maintenance to active predictive maintenance enabled with timely interventions to avoid expensive breakdowns and extensions of motor life cycle.

Industry Standards and Regulations

Adherence to International Standards

High efficiency permanent magnet motors are meant to be designed according to a number of international standards to ensure safety, performance, and reliability.

Besides instilling credibility in the manufacturer, these standards guarantee customers that the motors are really worth their pay in terms of quality and efficiency.

The understanding of the said standards should be absorbed into the minds of those companies that want to source motors with compliance in accordance to regulation.

Energy Efficiency Ratings

Energy efficiency ratings such as IE (International Efficiency) ratings are the cave in judging the performance of an electric motor.

It has provided useful information to the consumers about how much energy dissipation is being done for a given output of a motor.

Those knowledgeable about these ratings can wisely act in making acquisitions as to what should best, with respect to the consumer’s efficiency in a selection as well as in sustainability in company goals.

Conclusion

In summary, high-efficiency permanent magnet motors offer numerous advantages, such as reduced energy consumption, lower maintenance costs, and versatility across various industries.

For maximizing their use, it is vital to comprehend the role of support and maintenance.

It has been recommended that business ventures check out the different offerings for high-efficiency PMMs and their performance-enhancing support services.

Purchasing these motors is more than just a monetary decision; it is an investment in efficiency and sustainability.

For further inquiries on high-efficiency permanent magnet motors and the related support services, contact us.

Our team will assist you in making informed decisions that would be beneficial to your business in the long run.