Electric motors can be found in a wide range of products from everyday objects like small household appliances to heavily machined equipment.

More so, electrical energy is converted into mechanical energy and needs to create movement for any electric-powered item such as a fan or a pump or an electric vehicle- be it a car or even more complex machinery like robotics.

Learning how Motors are utilized in society and how they work will be of importance to all customers and business owners who plan to buy any motor-powered machine.

Given the objectives of this study, the characteristics of these two motors and that they are applied where needed shall be essential in assisting customers or what is more important for bussssiness owners in making well considered purchases of appropriate lessons properties of one motor and the application therof.

Why Motor Selection Matters

It is apparent that selecting the appropriate motor is not entirely about capability but as well as issues of economy and performance.

A given motor can be in a position to improve the process, save power, and extend the operating life of other components making it the right fit.

One the flipside, using an unsuitable motor can have repercussions, including an abstraction of benefits and increased costs of maintenance or the breakdown of machine.

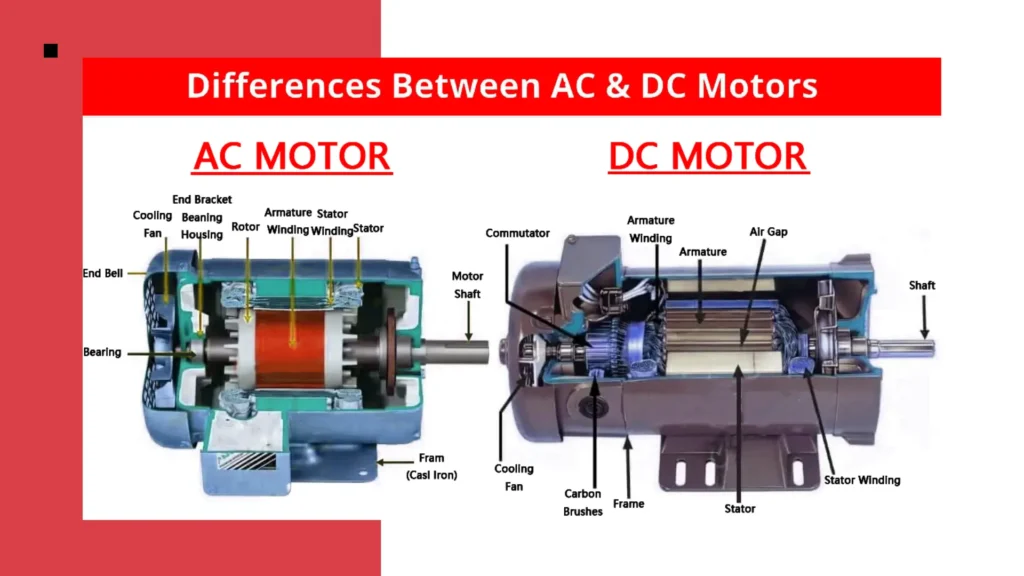

What are Permanent Magnet AC Motors?

Explanation and How It Functions

Brushless motors that operate on the principle of the permanent magnet ac (Nominal ac) (PMAC) use ac power to do this.

Permanent magnets attach the rotor helping the motor to produce a rotational magnetic field.

This development further allows the motor to perform in a better and more efficient way and is often used in different processes requiring consistent and precise transport.

And More:

Essential Guide to High Efficiency Permanent Magnet Motor Specifications

Kinds of PMAC Motors

Synchronous Motors

These motors rotate at the same speed constant speed at the same frequency as the AC power source, and are highly regarded for their efficiency and control in maintaining a particular speed despite changes in loading conditions, such as for conveyers and fans.

Asynchronous (Induction) Motors

In asynchronous motors, the rotor does not rotate in unison with the Orlando field as it is in synchronous motors.

This offers a more flexible design since the rotor can have higher speeds at lower speeds or low torque regions in which precise speed control is not necessary as is in a pump or compressor drive.

Common Applications

Electric Vehicles

Their efficiency and compact design are what make them best for powering electrical cars and even bicycles.

Robotics

The precision and reliability demanded by the operations of robots, is obtained from the Permanent Magnet-Less synchronous motors.

HVAC Systems

Heat, ventilation and air conditioning systems are able to maintain their energy performance parameters of motors’ operations due to existing motors technologies.

Industrial Automation

Every manufacturing sub segment has started using the PMAC motors for their high productive rates while complementing fashioned based production lines.

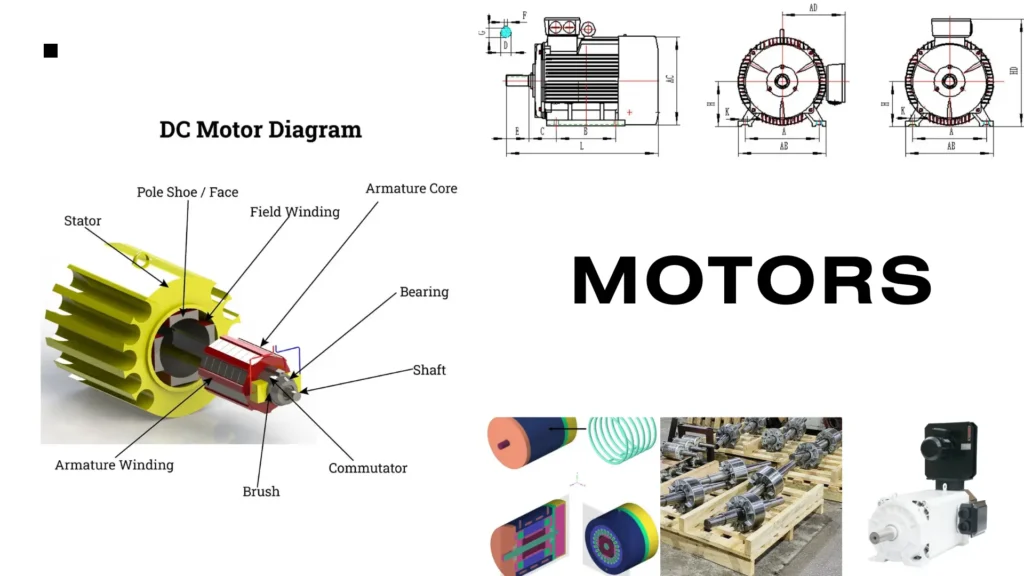

What are DC Motors?

Definition and Principles

Basically, DC motors harness direct current and transforms it into mechanical energy using the principles of electromagnetism, which is enabled by the flow of current.

In this context, it is the mobility of the motor that promotes the spinning of the armature, through a magnetic jolt caused by current as it flows through the motor.

Styles of DC Motors

DC Motors with Commutators and Brushes

The inclusion of commutator and brushes to these types of DC motors assists in a better performance.

They are quite popular motors where speed control is non-constraining, such as in toys and simple machinery.

Arrangement DC Motors As Brushless Type

Here, with the omission of the brushes, the level of maintenance decreases along with the percentage consumption.

One of the factors that increased the quantity of these motors is the use of brushless motors in applications with particularly high performance requirements – drones and electric cars.

Angle Motor

These motors are purposefully designed to provide precision control since they are capable of moving in small fixed intervals.

This feature makes it possible for these electric motors to be suitable for rationally designed applications that depend on correct positioning, one example of which is 3D printing process followed by case study of CNCs.

Usual Applications/End-Uses

Consumer Applications

Whether it is a hand-held dryer or a dishwasher, any home electronic device is likely to have a DC drive unit.

Motor Vehicles

Many cars have an abundant supply of DC drives used for passenger side and driver side windows, car seat controls, wiper arms and other car functionalities where fineness is often desired.

Belts Used for Transferring Goods

It has been made possible using electric motors for conveyor resistant belts.

Key Differences Between PMAC and DC Motors

Efficiency Comparison

In comparison to direct current motors, the permanent magnet AC motors are the motors that will most likely come out as having more efficiency on account of what they are capable of performing particularly on speeds.

The way the motors are engineered, they aim to ensure that the efficiency of the losses in the motor is kept at the minimum.

This has an advantage as it means that the overall energy consumption is reduced which means that the operational costs are also reduced.

Maintenance Needs

All direct current motors will always need constant checks mainly because as time goes by, the brushes wear and it means that the machine is not running at the depths initial capacity and is even likely to break down sometime soon and repair costs are also incurred.

This disparity makes PMAC motors the motors of No. 1 common among all the areas within the business.

Hospital General Use

It is generally more efficient for direct current motors to run at standard efficiencies and occasions fail to fulfil the specified duties and brush wear.

Running at peak efficiency the PMAC motor can be used in applications with high inertia and where the addition of weight is significant.

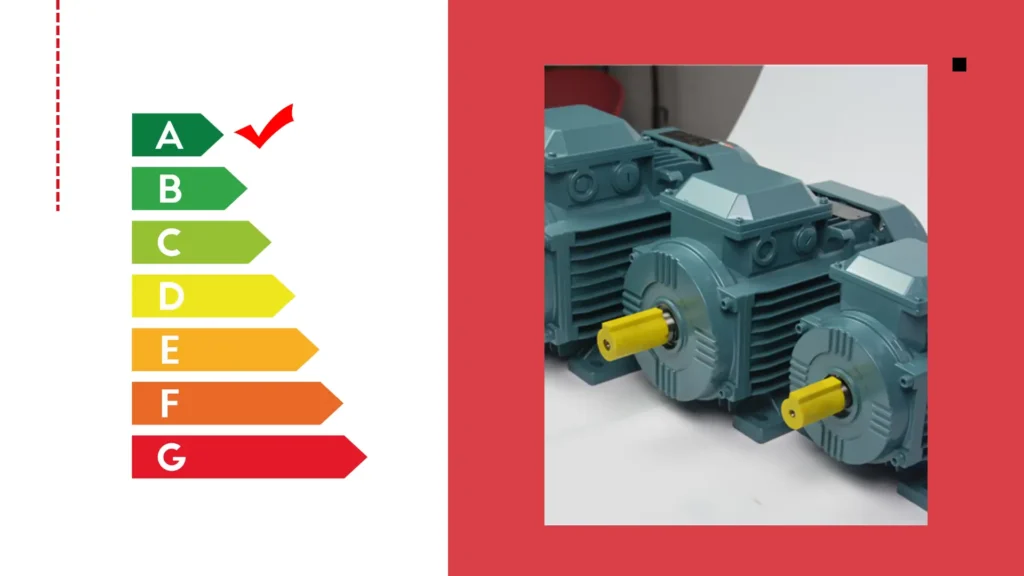

Advantages of Permanent Magnet AC Motors

Energy Efficiency

People can buy PMAC motors and in such case they are going to use them as energy than the powered almost regular motors.

And these motors are useful for the organization because as mentioned earlier, PMAC motors are mainly defense systems with around 30% efficiency, which is more less than traditional revenue vehicles which easily run on 14, 2% diesel propulsion engines.

Besides, according to market analysts, almost all the European freight transport corridors are congested.

Compact Reduction

PMAC motor geometrical reduction properties are good, suitable for their operation-hitherometric motor applications that are different from the stationary industrial principle.

It is difficult to use larger conventional ac rotating motors especially in electric vehicles.

In some applications’ design of PMAC motors the space utilization is even more than 50%.

Noiseless Performance

Another advantage of PMAC motors is the fact that they are characterized by noiseless operation.

Such functionality is especially attractive in areas where people work for the pollution prevention purposes mainly in residential, office and hospital environments.

The considerably reduced noise while running can also aid in work boosting motivation and spikes in the productivity levels.

Longevity

It is difficult to predict the longevity of a system.

However, PMAC motors will last longer especially compared to DC motors, thanks to the advances in technology and are some signs that there are companies or any other intentions to maintain existing or to build new containers.

Advantages of DC Motors

Basic Design

It may be concluded that dc motors are less complicated to manufacture and they house fewer sophisticated components such as micromechanical parts. This in turn results in a decreased overall cost of production.

Besides, servicing and analysis of the faults of dc motors are much simpler because of the features of their designs.

Performance

Dc motors have superior performance in areas where accurate regulation of speed is required.

The quality of control is the main advantage of such devices for robots, conveyor systems, and other automatic processes needing speed control.

This characteristic is of importance when it comes to operation in dynamic conditions which are frequent.

Affordability

The same DC motor in most cases, is cheaper in the first instance as compared to a BLDC motor.

Thanks to the widespread use of motor drives in virtually all equipment design for the present and future, motor technology being at an advanced stage assures customers that they will find what they are looking for.

Flexibility

To begin with, it should be noted that direct current motors are extremely effective and can be usedin many applicationsfrom areas of daily consumer products to big industrial machines.

In contrast to efficiency or lack of it, adaptability ensures that these products meet different requirements of various sectors and makes them a good option for any range of equipment.

Considerations for Choosing the Right Motor

Application Requirements Review

Choosing the right motor is not easy and it is food practice to try and understand the essence of the application like what the product or service will be used for and what basic load cycle can be expected.

Consequently, you must consider parameters such as the moment, the rotational speed, the weight and its range and the ideology, which will guide the optimization of the machine.

This activity will help to find a motor that will ensure the aforesaid device runs effectively and efficiently.

External and Operating Conditions

Apart from the use of the motor, another important factor that can affect power consumption and the durability of the device, is the working environment.

There are certain harsh conditions such as high temperature or humidity, dust or even vibrations which directly affect the motor performance.

Since it is likely to happen, a motor that is precise is helpful because it can enhance and increase its reliability while minimizing the incidence of maintenance.

Estimation of Costs

Inclusion of costs apart from the initial motor price and availability of energy efficient motors helps in budgeting.

This transportation costs if not managed well also add up the total costs incurred to the company.

When all the above figures are in order, then we can be able to have a clearer perspective in making an appropriate decision.

Investment Protection

To what extent would your choice of motor satisfy a change in the organization’s operations or upgrades in various equipment?

It is advisable to opt for a motor that can accommodate changes as they occur in the future as it is extremely beneficial.

Conclusion

Different electric motors’ features categorically are designed in such a scenario that some are rated to be fully efficient while others are fully economically viable and yet some some assritic constrict as mounting contract or design.

PMAC is distinguished by efficiency, durability and small form factor, while dc motor can increase efficiency and provide accurate control of a ratio.

However, in order to reduce or eliminate selection bias, it is important to know how to decipher this.

When making a recognition any buying circle should also play tradeoffs of shared and individual burdens between the member companies or men.

Interacting with motor suppliers to secure pertinent information and plan for buying or maintenance drills is also helpful when contrasted to conducting Selection direct.