The choice of motor technology is of great importance in an industrial system that has to operate within a very competitive context and make immense gains during running hours.

Permanent Magnet Synchronous Motors, or PMSMs, have proven themselves at the forefront for their brilliant names and respects for their exemplary performance and reliability across countless applications.

They are recognized as high efficiency and precision machines, moreover, they require much less maintenance, which makes them the most preferable when it comes to industrial applications that search for perfection in their procedures.

But, unfortunately, many tend to be confused and overwhelmed by the rather vast options from which their final decision is to be based.

Such a glorious article unfolds the entire buying drive into PMSM motors with respect to sure features, advantages, considerations about that technology, or why a person needs to make a purchase.

And More:

Why Should You Consider PMSM Motors for Your Industrial Applications?

Improved Efficiency

These motors are highly efficient, exceeding a good 90% efficiency.

High-power-to-low-cost ratios are relevant to industries finding ways to cut operational expenses.

Escalating power costs mean that motors of that sort can give substantial benefits over a long period. It becomes an economically correct convenience for businesses.

Performance Upgrade

Robustness, high torque, and speedier acceleration make them best suited for rough working conditions demanding high precision and speed.

Steady performance all the time, irrespective of the change in load, improves productivity and brings down the downtime.

Reliability and Endurance

With advanced technologies drawing them together, these motors with highly durable materials were born to flourish in arduous industrial environments.

The maintenance needs in this system reduce because of extended life and fewer replacements and repairs.

Operations can continue over a long period of time with the use of PMSMs without the fear of untamed breakdowns.

Environmental Benefits

PMSM also save on energy and carbon emissions thus help in more sustainability in the environment.

As more focus on sustainability in organizations, the use of PMSMs follows their corporate initiatives on social responsibilities.

The financial benefits of using the engines are there for any company.

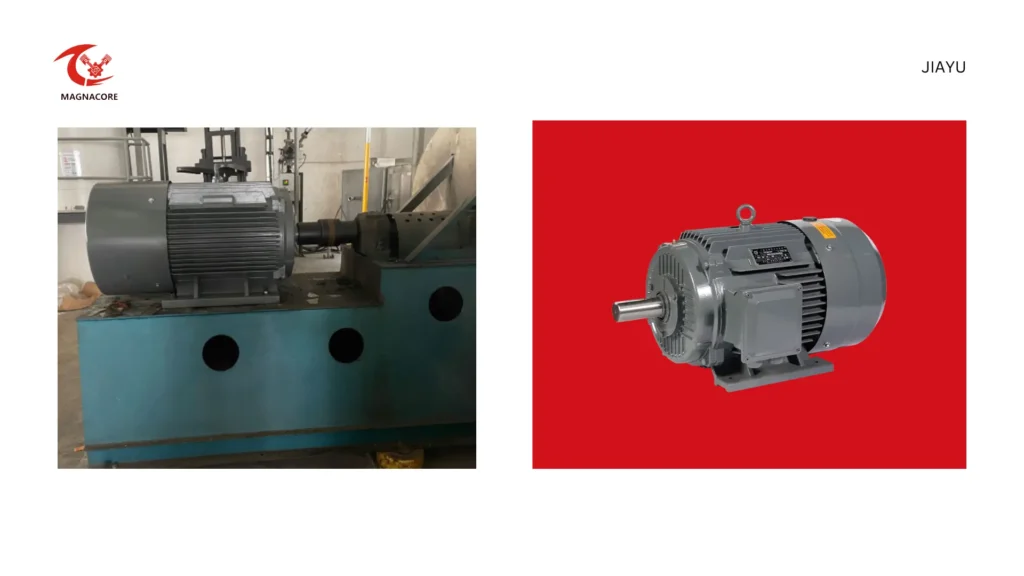

What Are the Key Features of PMSM Motors?

Super High Torque & Speed Control

One real distinguishing feature of PMSM is that it provides excellent torque characteristics and precise speed control, making it suitable for the most meticulous performance in the application.

It allows fair control and a smoother operation of processes, thus leading to an enhanced overall efficiency.

Trim Design

PMSM motors are hardly noticeable because of their small design-allowing smaller surfaces to be taken up and considered by applications in space-restricted places.

With a smaller footprint, these can be easily integrated into pre-existing systems without redesigns on a large scale.

Low Maintenance Requirement

Being a low maintenance feature of PMSM would make these fixings stand out.

While other traditional motors may need pretty much regular yearly maintenance, PMSMs are governed with near-zero continuous maintenance and afford extreme savings in labor, if maintenance crew could perform other more vital jobs required by the company.

Advanced Control Capabilities

PMSM motors are structured for the latest advanced control systems which cater for the most precise control of specific parameters and operational ratios.

The relevance of this feature arises from the fact that the motor indeed can afford businesses to optimize operation when used in specific applications based on what it produces for the company.

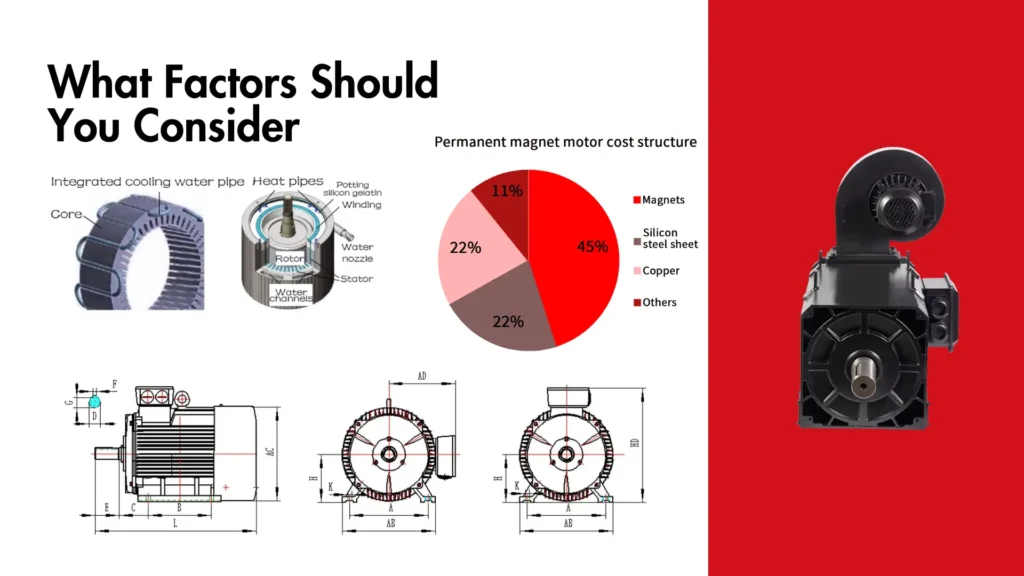

What Factors Should You Consider When Purchasing PMSM Motors?

Application Requirements

Defining the application-specific requirements is an important activity with the increasing role of load capacity, speed, and environmental conditions.

These will result also in the kind and specifications of PMSM needed for the application.

Clearly understanding these needs will guide you in the decision process of procurement.

Size and Power Ratings

The dimensions and energy efficiency of the PMSM require the proper fit for the intended application.

It is therefore an upgrade in performance and efficiency which might also prevent potential issues in the under- or oversized categories.

Budget Concerns

Establishment of a budget is essential for the acquisition of PMSMs.

It is important to know that the initial aspect cost on the purchase of this device price is as much as the long-term expenses there can be on energy use and maintenance.

Thus, a budget will prevent you from making an impulsive purchase.

Supplier Recognition

The consumer should research the credentials of potential suppliers.

The best suppliers in the region or country should be shortlisted on the basis of their history of providing excellence or combined performance.

Customer reviews will allow you to know suppliers.

How Can You Ensure Optimal Performance from PMSM Motors?

Routine Maintenance

Despite a lower cycle of maintenance with PMSMs, it helps quite a lot if one sets a certain protocol for verification practices to identify issues earlier than is possible.

This includes components inspected regularly and performance statistics checked for use and long life of the motors.

Monitoring Key Performance Indicators

Initiating a system of continuous monitoring of some performance indicators could potentially provide a good track record correlating efficiency, power consumption, and operational statuses.

This output then guides decisions on adjustments and/or upgrades to the unit for it to remain working in optimal fashion.

Staff Training and Assistance

There’s one better way for the company to perform properly and prevent operational issues, and this includes investing directly in a well-defined training order for its personnel with knowledge on the operation and maintenance of a PMSM.

Only few employees would need to run their power systems now in times of need.

What Are the Common Applications of PMSM Motors in Industry?

Robotics and Automation

PMSMs are extensively utilized in robotics and automation due to their precision and efficiency.

They facilitate smooth and accurate motion, making them optimal for operations such as assembly, packaging, and material handling.

HVAC Systems

In HVAC, PMSMs are known for their quality in saving energy and improving the performance.

Their efficient operation helps keep the right climate in the building by consuming fewer electrical powers.

Conveyors and Material Handling

PMSMs are widely used in conveyor and material handling applications.

Their reliability and efficiency, for instance, ensure the smooth operation of the equipment and thus facilitate the smooth motion of goods in industrial structures.

Electric Vehicles

Apart from the veracity above, the automotive industry has capitalized on reliance on PMSMs for electrical vehicles.

With PMSMs giving high-rated efficiency and performance, they have taken part in the movement from combustion drive trains to alternative driving systems.

How Can You Maximize Your Investment in PMSM Motors?

The Total Cost of Ownership Video

By evaluating their total expenditure, a business can develop a greater understanding of the financial future in relation to PMSMs acquisition.

This includes initial purchase expenses, electricity consumption, maintenance costs, and potential energy savings that at one time or another may help see the real value of the investment.

Customize Options

Customizing features could enhance PMSM performance according to the requirements of specific application or function.

Custom solutions are developed to address the specific needs of the client and increase efficiency, making leads seem like real investments.

Energy Efficiency Programs

Another way for your company to come up with income on the side is by enrolling in energy efficiency programs, improving on your investment in purchasing creations of PMSMs.

Often, these programs will have incentives in terms of rebates or grants for adopting energy-saving technologies, further improving the much-vaunted return on investment.

The Long-term Vendor Relationship

The quality of support as well as service, coupled with pricing from these long-term partners, could mean a lot.

Such a vendor will provide very useful and important insights and resources for your solution of the PMSMs investments, thereby further justifying each penny that is spent.

What Are the Future Trends for PMSM Motors in Industrial Applications?

Technology Advancement

Technological mastery of machine systems is continuously coming up with fresh success and efficiency in the PMSM.

Reinforcement of material, enhancement in control and features like smartness are putting the future in the D.C. motor.

Integrating with IoT

By integrating the PMSM within the broader scenario of IoT, monitoring real-time performance and control are facilitated which will be essential in tracking performance and predicting maintenance.

Market Growth Theory

The market for PMSM presents a prediction, growing extensively since companies crave energy-efficient and eco-friendly solutions.

Understanding trends in net markets and their projections will prepare businesses for future investment process.

How Do You Choose the Right Supplier for PMSM Motors?

Reviewing the Range of Goods

When weighing on a provider, it is a must to determine the lines of product and the extent they can serve diverse specifications.

A wide selection indicates the ability of the manufacturer to customize tailored solutions for various uses.

Support and After-sales Service

Determining the support levels that suppliers provide is fundamental.

Trust in the support service is intrinsic, as it can make all the difference in troubleshooting issues and get the most out of your PMSMs.

Warranties and Returns

Checking legal rights in warranties and returns could be vital in protecting your investment.

A long-lasting warranty could indeed could bring peace and protection from potential deficiencies or defects in performance.

Reviews and Testimonials

Reviewing consumers’ remarks and testimonials will give you an idea regarding the supplier’s reliability and quality.

Positive feedback from other businesses may help you make an informed choice when selecting a PMSM supplier.

What Are the Risks and Challenges in Purchasing PMSM Motors?

Upfront Costs versus Long-term Gains

Although generally having a higher initial cost, knowing what the long-term benefits of using PMSMs are important as companies compare the need to set up initial costs with potential future savings in energy and maintenance.

Compatibility with Current Infrastructure

Ensuring compatibility of the PMSM system with the existing infrastructure of the plant is crucial as this will enable the enterprise to do a proper assessment of current operations to prevent awkward integrations and ensure smooth transitions.

Potential Snags in the Supply Chain

Supply-side challenges can affect the availability and pricing of PMSMs. When they consider their buying needs, businesses must also take into consideration supplier dependability and probable interruptions.

Understanding the Basics of Maintenance

Although PMSMs require maintenance on a needs-be basis, know-how about the kinds of maintenance required in each individual case is essentially an important criterion.

Consequently, a company would be able to eliminate unplanned downtime and costs by being appraised of the necessity of any maintenance and when they must be performed.

Conclusion

Therefore, investment in PM-SCP is an influential point that anybody will claim in the good deeds that result from industrial implementations.

Maximum overall efficiencies and performance can minimize environmental drawbacks.

Nowadays, there is a need for understanding key characteristics, advantages, and concerns discussed together with PMSMs to lead organizations through informed decisions in alignment with operational targets.

Application ties, budget constraints, and supplier reputation become the major determinants of a successful investment.

Nevertheless, the longevity of returns may also be optimized through proper maintenance as well as strategic partnerships. PMSMs are certainly going to be key players in the future design of motor technologies.

Continuing right by managing and staying alerted will allow businesses to take maximum advantage of PMSMs, maintain their competitiveness in rapidly changing surroundings.