As the electric vehicle (EV) industry accelerates rapidly, the choice of motor technology becomes pivotal in determining performance, efficiency, and the overall driving experience.

Rare earth permanent magnet synchronous (PMS) motors have emerged as a superior alternative to traditional induction motors, offering significant advantages in power output, energy efficiency, and design flexibility.

This article delves into the reasons why rare earth PMS motors are outperforming induction motors in EVs and their implications for the future of electric mobility.

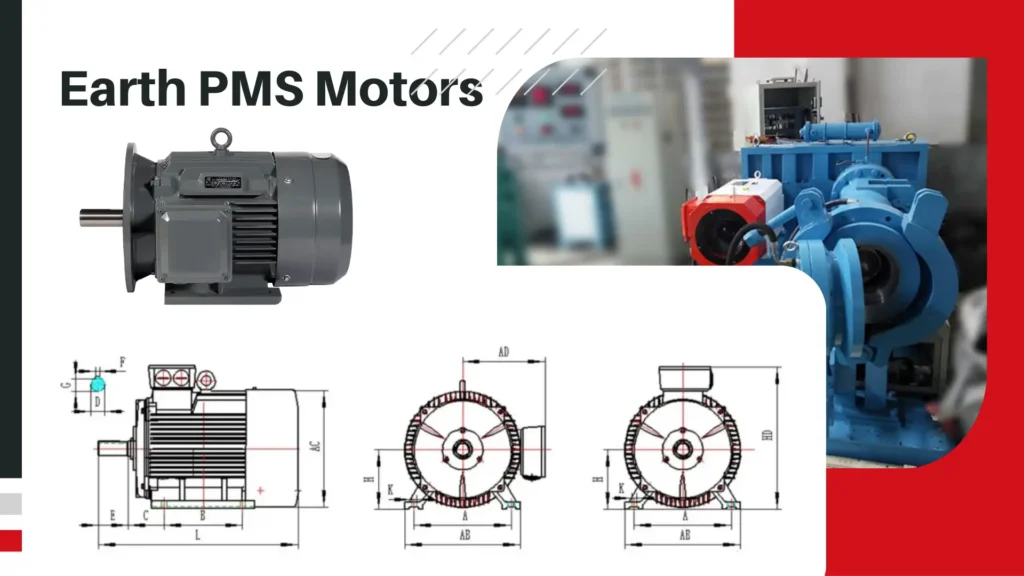

What Are Rare Earth PMS Motors?

Permanent Magnet Technology

Rare earth PMS motors utilize powerful magnets crafted from materials such as neodymium and samarium-cobalt.

These rare earth magnets generate a strong and consistent magnetic field that enhances the motor’s performance and efficiency.

The incorporation of these advanced materials allows for a compact design while delivering high torque and power density.

This technology ensures that the motors can operate effectively even under varying load conditions, making them ideal for the demanding requirements of electric vehicles.

Synchronous Operation

These motors operate at a fixed speed that is synchronized with the frequency of the power supply.

This synchronous operation ensures precise control over the motor’s performance, allowing for efficient power delivery.

By aligning the motor speed with the electrical frequency, PMS motors minimize energy losses, resulting in higher overall efficiency compared to induction motors, which often operate at variable speeds and can experience slip losses.

Compact and Lightweight Design

The use of rare earth magnets allows for smaller and lighter motors without sacrificing power output.

This compactness is crucial for EV design, where weight reduction can significantly enhance performance, efficiency, and range.

A lighter motor contributes to better vehicle dynamics and improves overall handling, making the driving experience more enjoyable and responsive.

How Do Rare Earth PMS Motors Compare to Induction Motors?

Higher Efficiency

Rare earth PMS motors achieve efficiencies of 95% or higher, compared to the 85-90% efficiency range of traditional induction motors.

This enhanced efficiency reduces energy waste and extends the driving range of electric vehicles, allowing manufacturers to offer models that can travel further on a single charge.

The superior efficiency of PMS motors translates into lower energy costs for consumers, making EV ownership more economical over time.

Superior Power Density

PMS motors deliver greater power per unit of weight, making them particularly well-suited for high-performance electric vehicles that demand quick acceleration and robust performance.

This high power density allows manufacturers to design vehicles that can compete with traditional internal combustion engine vehicles in terms of performance while benefiting from the advantages of electric propulsion.

Better Thermal Management

The design of PMS motors generates less heat during operation compared to induction motors.

This reduced heat generation decreases the need for complex cooling systems, enhancing the reliability and longevity of the motor.

Improved thermal management is essential in electric vehicles, where excessive heat can lead to performance degradation and increased maintenance needs.

What Makes Rare Earth PMS Motors More Efficient?

Reduced Energy Loss

The incorporation of permanent magnets eliminates the need for rotor current, which is a significant source of energy loss in induction motors.

By minimizing energy loss, PMS motors can operate more efficiently across various driving conditions, resulting in better overall performance and extended battery life for electric vehicles.

Precise Speed Control

The synchronous operation of PMS motors allows for precise control over motor speed, optimizing performance for different driving scenarios.

This capability ensures that the motor can adapt to various conditions, such as acceleration, cruising, or deceleration, enhancing the overall driving experience.

The ability to maintain consistent performance under varying loads and speeds is a crucial advantage for EVs.

Lower Maintenance Requirements

PMS motors have fewer moving parts and do not utilize brushes, which are common in other motor types.

This reduction in mechanical complexity leads to lower maintenance requirements, as there are fewer components subject to wear and tear.

The long-term reliability of PMS motors can significantly reduce operating costs for EV manufacturers and consumers alike.

Why Are Rare Earth PMS Motors Ideal for EVs?

Extended Driving Range

The high efficiency of PMS motors directly contributes to longer battery life, a critical factor for the widespread adoption of electric vehicles.

Consumers are increasingly concerned about range anxiety—the fear of running out of battery power before reaching their destination.

By enabling longer ranges between charges, PMS motors help alleviate this concern, making EVs more appealing to potential buyers.

Enhanced Performance

PMS motors provide instant torque, allowing for faster acceleration and a smoother driving experience.

This immediate power delivery improves the responsiveness of electric vehicles, enhancing their overall performance.

Whether for city driving or highway merging, the ability to deliver power instantaneously makes driving electric vehicles a more dynamic and enjoyable experience.

Compact Design

The smaller size of PMS motors allows for more flexible vehicle design. This design flexibility can lead to better weight distribution, improved aerodynamics, and increased cabin space.

Manufacturers can take advantage of this compactness to create innovative vehicle layouts that enhance comfort and functionality for passengers.

What Are the Challenges of Using Rare Earth PMS Motors?

Cost of Rare Earth Materials

The production of rare earth magnets involves materials that can be expensive, particularly neodymium and dysprosium.

While the upfront cost of PMS motors might be higher than that of induction motors, their long-term savings in energy consumption and maintenance can offset this initial investment.

Manufacturers are continuously exploring ways to reduce costs, including optimizing the design and production processes for these motors.

Supply Chain Dependencies

The global supply of rare earth materials is concentrated in a few countries, mainly China.

This concentration poses potential risks for manufacturers, as geopolitical factors or trade restrictions can disrupt the supply chain.

Manufacturers are increasingly aware of these risks and are exploring alternative sourcing strategies to ensure a stable supply of critical materials.

Recycling and Sustainability

While rare earth magnets offer high efficiency, their production and disposal raise environmental concerns.

The mining and processing of rare earth elements can have significant ecological impacts.

Manufacturers are focusing on developing sustainable practices, including recycling rare earth magnets from end-of-life products, to mitigate these environmental challenges and promote a circular economy.

How Are Manufacturers Addressing These Challenges?

Developing Alternative Magnet Materials

Research is underway to create magnets with reduced rare earth content or entirely new materials that offer similar performance characteristics.

Innovations in magnet technology could lead to lower costs and reduced environmental impact, making PMS motors more accessible and sustainable.

Improving Recycling Technologies

Efforts to recycle rare earth magnets from end-of-life products are gaining traction.

Enhanced recycling technologies can help reclaim valuable materials, reducing dependency on newly mined resources and minimizing waste.

By investing in recycling initiatives, manufacturers can contribute to a more sustainable future for the EV industry.

Diversifying Supply Chains

Manufacturers are actively exploring new sources of rare earth materials and investing in local production to mitigate supply chain risks.

By diversifying their supply chains, companies can reduce their reliance on a single source, enhancing their resilience against potential disruptions and ensuring a steady supply of critical materials.

What Are the Long-Term Benefits of Rare Earth PMS Motors?

Lower Total Cost of Ownership

Despite higher upfront costs, PMS motors offer significant savings in energy consumption and maintenance over their lifespan.

The long-term efficiency and reliability of these motors can lead to a lower total cost of ownership for EV owners, making them a financially sound choice in the long run.

Environmental Impact

The efficiency of PMS motors contributes to a reduced carbon footprint for electric vehicles.

By improving energy utilization and reducing emissions associated with electricity generation, PMS motors align with global sustainability goals and help mitigate climate change.

Market Competitiveness

EVs equipped with PMS motors can offer superior performance and range, giving manufacturers a competitive edge in the rapidly growing electric mobility market.

As consumers increasingly seek high-performance, efficient vehicles, manufacturers that adopt PMS technology can differentiate themselves and capture a larger share of the market.

How Do Rare Earth PMS Motors Shape the Future of EVs?

Enabling High-Performance Models

PMS motors are driving the development of high-performance electric vehicles, from sports cars to heavy-duty trucks.

The ability to deliver high power and efficiency makes these motors ideal for applications requiring robust performance, thereby expanding the range of electric vehicle offerings in the market.

Supporting Energy Transition

By enhancing the efficiency of electric vehicles, PMS motors play a crucial role in accelerating the transition to renewable energy sources and reducing dependence on fossil fuels.

The growing adoption of EVs powered by PMS motors supports broader sustainability initiatives and contributes to cleaner urban environments.

Driving Innovation

The compact and versatile design of PMS motors is inspiring new vehicle architectures and technologies, such as in-wheel motors. These innovations can lead to the development of more efficient vehicle designs, improved handling, and enhanced overall performance.

As the automotive industry evolves, PMS motors will continue to be at the forefront of technological advancement.

Conclusion

Rare earth PMS motors are revolutionizing the electric vehicle industry by offering unparalleled efficiency, performance, and design flexibility compared to traditional induction motors.

While challenges such as cost and supply chain dependencies exist, ongoing innovations in materials, recycling, and manufacturing are paving the way for a sustainable future.

For EV manufacturers and consumers alike, rare earth PMS motors represent a smarter, more efficient choice that is driving the electric mobility revolution forward.

As the industry continues to evolve, the adoption of PMS motors will undoubtedly play a central role in shaping the next generation of electric vehicles, making them more efficient, powerful, and environmentally friendly.