The Cost Savings of Buying Permanent Magnet Synchronous Motors in Bulk

In the competitive industrial atmosphere today, businesses are always trying to find ways to better operations and cut overhead.

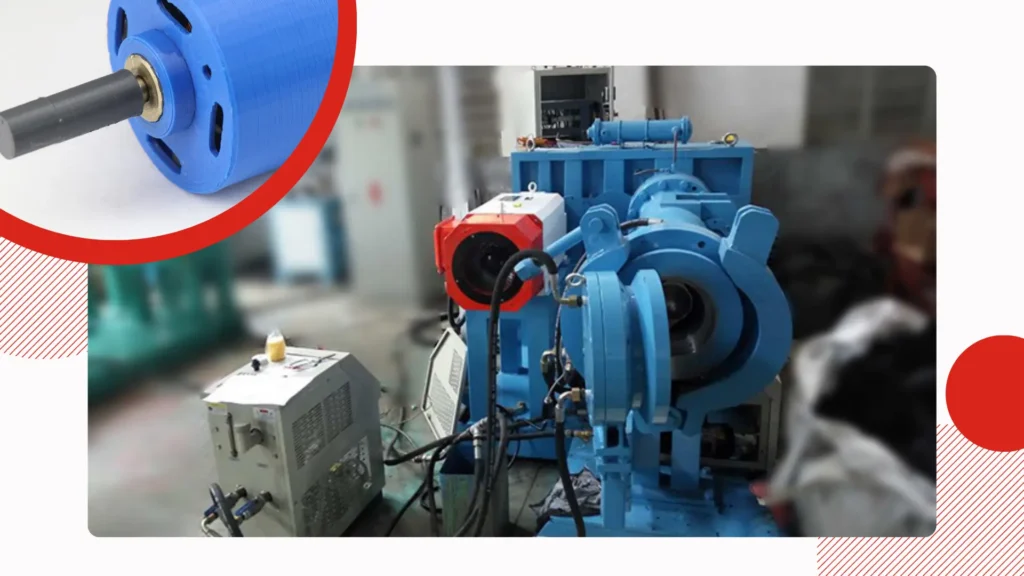

One such area of potential growth would be through the use of Permanent Magnet Synchronous Motors.

These motors offer unparalleled efficiency and reliability, making them very coveted for manufacturing and renewable energy uses.

For companies that are planning to invest a large fortune in PMSMs, buying these motors in bulk can save the company a lot in terms of investment.

This article will look at the financial and operational gains one is going to enjoy with the bulk purchasing of PMSMs and show one why this makes strategic sense for businesses of all sizes.

Understanding Permanent Magnet Synchronous Motors

Permanent Magnet Synchronous Motors, commonly referred to as PMSMs, are a class of motors utilizing permanent magnet magnetic fields.

Contrary to conventional induction motors that rely on electromagnetic induction, permanent magnet synchronous motors promise higher efficiency and performance levels.

Efficiency in this context means low energy consumption, lesser operational costs, and minimized maintenance needs-actually what every business enterprise is looking for in an effort toward optimum operation.

Key Features of PMSMs

High Efficiency

PMSM is normally characterized by the fact that they have the ability to run with high efficiencies, usually above 90%.

Surprisingly, this makes a very strong difference in operating costs because a larger percentage of consumed electrical energy is turned into mechanical energy.

For those companies whose operations are hugely dependent on motor variable loads-such as manufacturing lines, HVAC, and conveyor belts-this may translate to huge savings after some time.

On top of enhancing cash flow, lower energy bills are synonymous with contributions to sustainability goals through reducing the overall carbon footprint from operations.

Compact Design

PMSMs are made to a size that enables them to fit into compact areas, which the traditional motor cannot.

This mostly applies to applications in robotics, electric vehicles, and industrial automation, where space is an expensive commodity.

A smaller motor footprint implies a reduction in the infrastructure cost that will be required for installation.

This flexibility in layout enables businesses to manage their layouts better and, in the process, reduce modifications in the facilities.

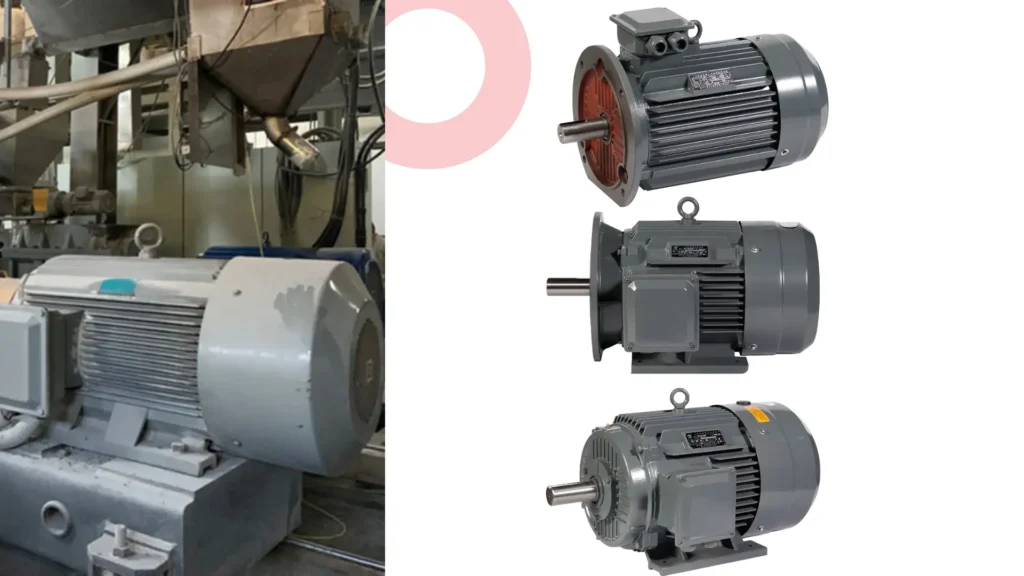

Low Maintenance

With fewer numbers of moving parts, PMSMs are less prone to wear and tear.

This durability equates to less maintenance cost and reduced downtime-a factor very crucial for companies operating on continuous processes.

Reduced maintenance also means personnel can be freed from routine upkeep and focus on more productive endeavors.

The resultant efficiency saves not only dollars but also improves productivity by allowing an enterprise to utilize its resources more judiciously.

The Benefits of Buying in Bulk

Buying in bulk has a number of financial advantages when it comes to Permanent Magnet Synchronous Motors that will help a company’s bottom line considerably.

Cost per Unit Lessened

The immediate advantage with bulk purchasing is that the per-unit cost goes down.

Manufacturers give volume discounts, and so, the overall spending becomes much lesser.

For example, an entity purchasing 100 motors may receive a price break that would grant them each motor at much lower costs than if they were purchasing them individually.

This discount, therefore, enables companies to keep within their budgets and reinvest money into other vital sectors, such as research and development, staff training, or simply improving operations in general.

Reduced Shipping and Handling Costs

Apart from reduced unit cost, bulk buying is usually equated to reduced shipment and handling costs.

Since there are fewer deliveries, it would imply less frequency of transportation costs and, hence, reduced logistical overheads.

For companies, especially those operating on small margins, this would be considered savings enough. Less frequent deliveries also imply lesser complexity in the management of inventories and a smoothing of supply chain operations.

This simplicity can free so much valuable time for the staff to engage themselves in more strategic activities rather than mere logistics related to the dispatch of shipments.

Negotiation Power

Buying in bulk reduces the costs and enhances the bargaining power a company may have over its suppliers.

It is because with a commitment to a large quantity order, one may negotiate for favorable terms, which can include extended warranties, attractive payment conditions, or even value-added services such as technical support.

This may consequently result in the long-term partnership that would further benefit the company.

Good relationships with suppliers can result in priority service; thus, the businesses are guaranteed to get the support when they actually need it.

And More:

- Wholesale Purchase of High-Performance Permanent Magnet Motors Made in China

- A Comprehensive Guide to Permanent Magnet Synchronous Motor Wholesale in China

Operational Efficiency

While the financial benefits from bulk purchasing are huge, the operational efficiencies gained can be as important for businesses.

Consistent Supply

Another advantage with buying in bulk is the guarantee of having a steady supply of PMSMs.

In turn, this avoids delay caused by waiting for the arrival of a fresh consignment. In most industries where downtime causes heavy financial losses, it is important to have a steady supply of motors.

Businesses can, thus, go ahead and schedule their production accordingly without the stress of potential shortage, which would lead to paralyzing activities and affecting customer satisfaction.

Standardization

Bulk buying also allows for a standardized type of equipment within the operations.

If one company is using the same type of motor throughout its processes, it can easily train employees, and the maintenance procedure is uniform.

In many ways, such standardization may increase their efficiency as workers get acquainted with the different pieces of equipment and their mode of operation.

Furthermore, operating uniform equipment means less headache regarding spare part inventories, since fewer types of components will have to be kept in stock.

This not only simplifies the inventory but also reduces the number of related costs associated with the maintenance of such wide-ranging parts.

What are the advantages of PMSMs?

Super High Efficiency

Efficiency is there as PMSMs excel even towards the point of 90% or more.

This being much more the electrical energy is converted into mechanical energy, which turns into great savings on energy bills.

Efficiency will further save operational costs as well as contribute to its carbon footprint as they run continuously in most industries. Thus, aligning with global sustainability goals.

Compact Design

The very design of PMSMs makes them compact by principle because of permanent magnets; hence, smaller footprints in machinery make these motors perfect for limited spaces.

The smooth interior assembly result also contributes to the overall weight reduction of the entire machine, and this becomes useful in most applications for electric vehicles and aerospace-if everything counts in resulting weight.

Little Maintenance

PMSMs have fewer moving parts compared with the traditional motors, especially that which has brushes.

Minor complexity thus makes it less susceptible to wear, which directly contracts into maintenance.

Maintenance costs, therefore, become less among business people’s concerns of loss due to downtime.

The lifetime of these motors, which can perform for decades without major interventions, just improves the argument in their favor.

How can bulk purchasing reduce costs for PMSM businesses?

How Volume Pricing Works

By placing orders for a PMSM in bulk, companies can bargain better prices with the suppliers.

Such bulk purchase discounts can cut down a lot of costs for companies that require the installation of numerous motors for manufacture or use in expanded projects.

The unit price itself reduces profit margins for the company and thus makes much room for reinvesting in other parts of the business.

Lower Shipping Costs

When these purchases are really large, economies of scale also apply to shipment.

Usually, as the quantity of items transported increases, the average amount paid per item will go down.

This is of great advantage to businesses that operate under tight margins since a few cents make a significant difference.

Further, it reduces the number of shipments and simplifies logistics, freeing administrative staff from managing many deliveries.

Mutual Growth between Supplier and Buyer

With large quantities purchased, it forms a basis for a growing partnership between businesses and their suppliers.

Long-term relationships will promote better service priorities for product availability and support during times of high demand.

Such relationships can determine other benefits for other future purchases, such as extended payment terms and additional discounts.

Thus, making the partnership exciting altogether.

What factors should be considered when buying PMSMs in bulk?

Application Requirements

Specific application considerations regarding the PMSM should be made before purchase by enterprises.

Factors such as required torque, operation speed, as well as environmental conditions (like temperature and humidity), must be assessed thoroughly to select the appropriate motor type.

Defining these actually helps understand the required performance of PMSMs under given working conditions.

Quality Assurance

When interested in buying these motors in bulk, the question of quality arises.

High-quality PMSMs are therefore to meet relevant industry standards and certifications to be regarded as reliable and safe.

Verification of the supplier’s manufacturing processes, quality control measures, as well as product testing protocols mitigates risks regarding defective products, while also ensuring consistent performance.

Manage Inventory

Effective inventory management is very essential in this case for companies which tend to buy in bulk; it should have measures which would help manage stock levels in a way to avoid excess inventory which ties capital and space.

Just-in-time inventory practices and/or inventory management software would help a business keep a balance in stock needs while ensuring that it does not overcommit resources to meet demand.

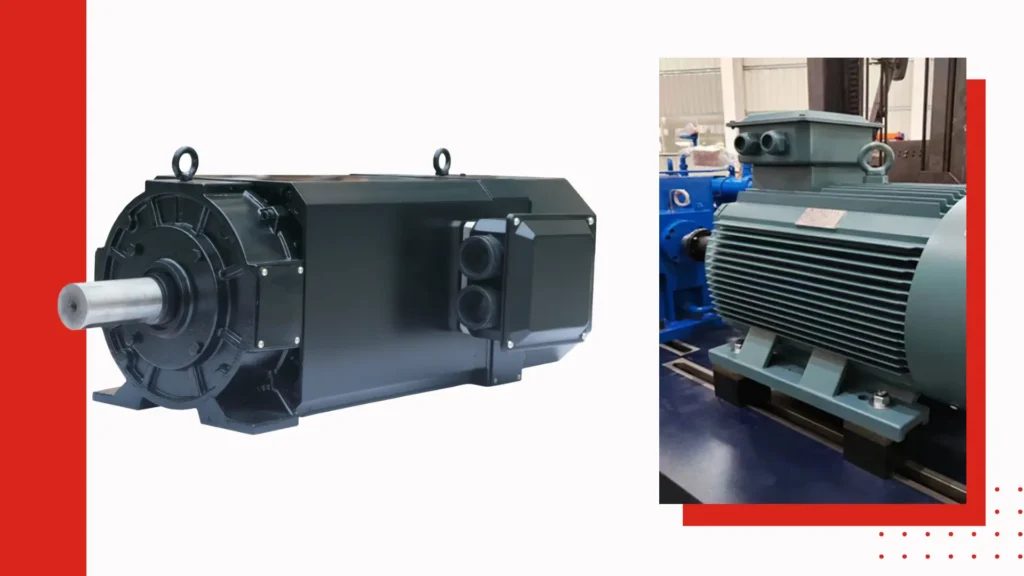

How do PMSMs compare to other types of electric motors?

Characteristics of Performance:

In terms of performance, PMSMs generally outperform the conventional types of motors like induction motors in torque-to-weight ratio as well as in the efficiency.

These advantages would make PMSMs that much more appealing for applications demanding high performance in a precise and reliable manner, robotics and automation being prime examples.

Sustaining efficiency at high levels across the full range of operating conditions has also further increased their attractiveness for energy-needed applications.

Control Complexity

PMSM will give high efficiency and performance, but controlling it will be much more complex than most of the simpler motor types.

The users must invest in the advanced controllers, for example, field-oriented control (FOC), for installation; they will face the challenge of a more sophisticated setup cost and complication for initiating the system comprising the advantages of improved efficiency and performance.

Cost Aspects

PMSMs offer such features that their initial cost is more than that of conventional electric motors, but their performance efficiency and relatively low maintenance compensation will subsequently lead to a lower total life cost.

Their cost effectivity can particularly matter in applications where motors are continuously running.

A detailed cost-benefit analysis can throw light on the potential savings and make the initial investment more persuasive for businesses pursuing the use of PMSMs.

Conclusion

Bulk purchase investment in Permanent Magnet Synchronous Motors is one that would make much business sense for companies desirous of raising their efficiency levels while seeking to cut down on costs.

The financial windfalls of reduced price per unit, lower shipping cost, and increased bargaining powers are just great. Of equal, if not greater, importance are the operational efficiencies accruing from the stability of supplies and standardization.

The company can then weigh the benefits that may be reaped from bulk buying to assist management in making prudent decisions that will help enhance efficiency and contribute toward long-term profitability.