Permanent magnet motors (PM motors) are a sort of modern electric motors that use permanent magnets instead of electromagnets to generate the magnetic field.

PM motors find applications in all areas including industrial machinery, electric vehicles, and renewable energy systems.

Their reliability and consistent performance make them the materials that run inside all energy-efficient technologies.

Quality assurances ensure that motors leave with reduced defects, hence enhanced reliability, and within industry compliance standards.

This would also mean that the buyer most be able to understand such processes to enable him to make an educated decision at purchase, aligned to his operational needs.

This paper discusses the quality assurance practices of the high-performance permanent magnet motors manufactured in China.

The vital standards, testing procedures, along with certifications that show the motors meet international quality standards will be detailed in this article for prospective buyers to make the informed choice of products that suit their applications.

Also Read:

Quality Assurance in Permanent Magnet Synchronous Motors – Chinese Supply Chain Strategies

Applications in Wind Energy

Lighting up Wind Turbines

PM motors are the engines running wind turbines, converting the kinetic energy from wind into electrical energy.

They should be designed so that the larger part of the energy of the wind is converted into electricity.

Of course, the higher the yields in terms of electric power generation, the more sustainable wind is as a renewable energy source.

More Reliable

Reliability is very important in the performance of wind turbines.

PM motors are built to sustain the vagaries of such inhospitable atmospheres, strong construction putting so little demand on maintenance.

Thus, an efficiency in operation combined with a reduced downtime translates into maximized project productivity relative to wind energy.

Compact and Light Weight Design

The compactness of PM motors leads to lighter turbine structures, thereby improving the aerodynamic efficiency of such wind turbines.

Thus, lighter turbines are expected to harness more wind energy at less material consumption and thus lower manufacturing and installation costs.

The above becomes economically viable as far as the PM motors belonging to wind energy developers are concerned, who are optimizing their projects.

And More:

High-Performance Permanent Magnet Motors in Renewable Energy Systems

Solar Energy Applications

Optimizing Solar Tracking

PM motors are the core part of solar tracking systems that vary the position of solar panels during the day to expose them to maximum sunlight in the solar energy systems.

Hence, energy, thus harnessed, will generally be enhanced by these motors to more efficient solar power generation.

This optimization is the significant investment to yield the best return on investment in such installations of solar energy.

Efficient Energy Conversion

PM motors are also used in inverters in solar energy systems.

These inverters convert direct current from solar panels into alternating current for use in homes and businesses.

The performance of PM motors is crucial as to the power savings while converting power from DC to AC.

Thus, saving a significant part of the electricity generated becomes vital.

Helping Energy Storage Solutions

Energy storage becomes a necessity to the extent that it becomes important for proper balancing of the intermittent nature of solar power.

PM motors perform an important activity in energy storage systems, that is conversion and distribution of excess energy.

This ensures that there is assurance that stored energy is well utilized in absence of sunlight, thus increasing the reliability of solar energy systems.

Hydroelectric Energy Applications

Generate Electricity By Water Flow

In hydroelectric plants PM motors convert the mechanical energy of the flow of water into electrical energy.

It features very high efficiency and thus higher energy yields, which is a major component of sustainable hydroelectric systems.

PM motors contribute to overall output improvement in the overall hydroelectric facilities.

Pumped Storage Systems

Pumped storage plants use PM motors for the control of water flow and the release of energy.

These systems are critical for balancing the energy supply and energy demands during peak usage periods.

Movement of water more effectively using PM motors improves the efficiency of energy storage and distribution systems.

Low Maintenance Requirement and Longevity

PM motors are much less maintenance-intensive than conventional motors used in hydro applications.

The reduced amount of maintenance not only reduces operational costs but also prolongs the lifetime of the motors, thus turning them into a really cost-effective option for hydroelectric plants.

Applications of Bioenergy

Biogas System Powering

PM motors are being used in biogas production to perform mixing and pumping through these processing mechanisms.

If they operate efficiently, these operations ensure that biogas systems work smoothly for maximum energy recovery from organic waste.

It makes this application, therefore, one of PM motors in the pragmatic diversification for sustainable waste management alternatives.

Improving Biomass Conversion

PM motors are also responsible for driving equipment used in the conversion of organic materials to usable energy in biomass energy applications.

Their proven reliability and efficiency are considered crucial for ensuring the uninterrupted operation of such systems.

Powering Waste-to-Energy Facilities

Waste-to-energy plants make use of PM motors to improve the energy aspect of waste products.

This highly contributes to waste reduction and sustainable energy production.

PM motors are in liaison to help achieve the global goal of minimizing the use of landfills and promoting renewable energy sources.

Grid Integration and Energy Management

Smart Grid Applications

Permanent magnet motors have a role in smart grid technologies by improving efficiency for better managing energy distribution and acting as a good link for renewable integration within the system, which in turn increases the overall reliability and stability of the system.

Load Balancing and Demand Response

PM motors, in energy management systems, enable load balancing and demand-response programs; that is, they allow to rapidly vary power supply according to instantaneous demand and are more valuable in preventing overloading and outages of the grid during peak hours.

Improvement of Energy Storage Systems

It should be clear that PM motors add efficiencies to energy storage systems in terms of improvements to manage renewables.

With the availability of options, these motors are capable of enhancing energy transfers and distribution, thereby creating a stronger resilience for energy infrastructures that will allow optimally effective usage of renewables.

Benefits of High-Performance PM Motors

Excellent Energy Efficiency

PM motors efficiently save energy losses in the energy conversion process, which is an important requirement especially in renewable energy application.

This would lead to reductions in operational costs and thus sustainable energy systems reduce these businesses energy bills and conserve them as feasible options.

Environmental Consequences

PM motors provide a lot of energy with a reduction in waste production; as a result, they reduce the overall carbon footprint generated through energy production.

They can fit just as with a renewable energy system for applying to current sustainability goals by which companies can fulfill their environmental commitments.

Cost Savings over a Long Time

In that it may have a larger initial upfront cost than normal kinds of motors, investment in performance PM motors does cost much when compared to their energy and maintenance savings over a longer period of time.

This increases attractiveness from a business point of view among those which value improving their bottom lines while going about sustainable practices.

Challenges and Considerations

Initial Investment Costs

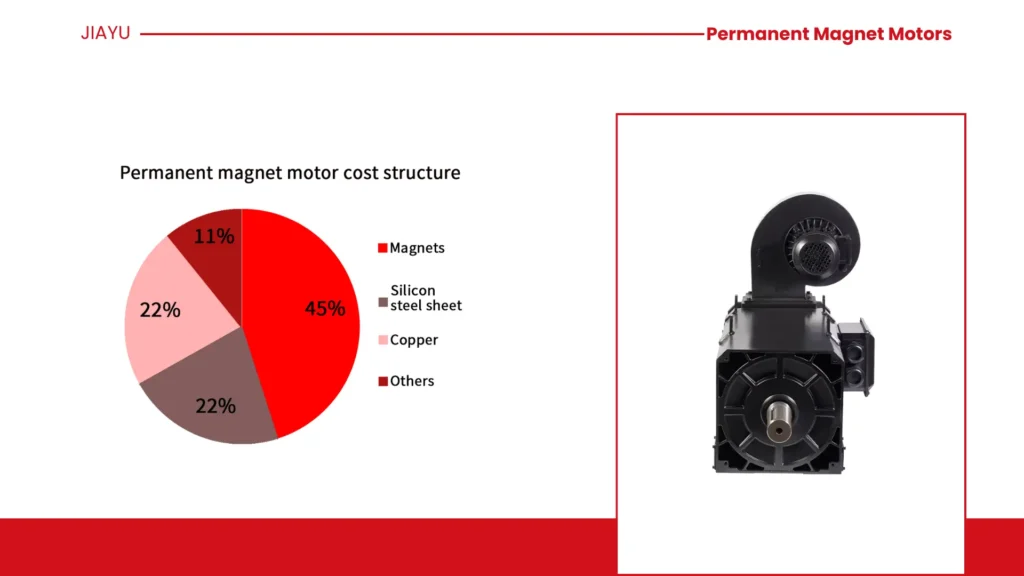

In fact, compared to conventional motors, the initial cost of PM motors is considerably more.

Before buying, the cost of purchase will weigh against the long-term savings and efficiency dividends.

Supply Chain and Material Availability

The manufacture of PM motors is dependent on rare earth materials, hence availability challenges in terms of supply chain and environmental sustainability.

Sustainable sourcing practices have to be addressed by manufacturers to safeguard against these issues and ensure a secure supply of materials.

Technological Integration

Further investment in technology and training may be required to integrate PM motors into already functioning renewable energy systems.

It needs to be known to the businesses whether they have the capacity and preparedness for such transitions.

Conclusion

High-performance permanent magnet motors made in China implement serious strict quality assurance practices.

This includes adherence to international standards as well as rigorous testing processes and robust customer support systems, meant to meet and exceed expectations as makes it mandatory for a buyer to comprehend these systems before making a choice of any PM motors for their applications.

With the emerging interest in renewable energy solutions and applications, high-efficiency PM motors will project more significantly.

Further improvements in design and materials for the motors would push their performance and applicability to a substantial percentage of energy sectors, positioning PM motors as key elements in transitioning to a sustainable energy future.

It is indeed investing into a sustainable future. Contact us today to learn about high-performance PM motors and how they can benefit your business towards a sustainable future.