As industries mature and energy-saving possibilities become a must, with this inclination grows the preference of many applications into the use of Permanent Magnet Synchronous Motors (PMSMs).

These motors are known as the new generation of powerful machines having the best performance, reliability, and efficiency suitable for nearly anything, from industrial machinery to electrical vehicles.

So, investing in PMSMs is better known not only on how these next-gen motors technically pave the way for industry but further more on how to decide if they are simply worth the additional expense than is allocated for the budget.

Moreover, researching the pricing of Permanent Magnet Synchronous Motors will get you through the entire enigma and may enlighten prospective buyers with all they need to know to make the right decision.

Through gauging up features affecting the pricing, benchmarking typical costs, trailing expenses etc., enterprises can possibly square their budgets in terms of operations needs and objectives?

From purchasing new equipment for the first time to upgrading facilities, understanding PMSM pricing is crucial in maximizing investment and help to ensure the smooth and non-leaky operations of one’s processes.

And More:

Permanent Magnet Synchronous Motors: AC vs. DC

Cost Savings on Permanent Magnet Synchronous Motors

What Factors Influence the Price of Permanent Magnet Synchronous Motors?

Material Quality

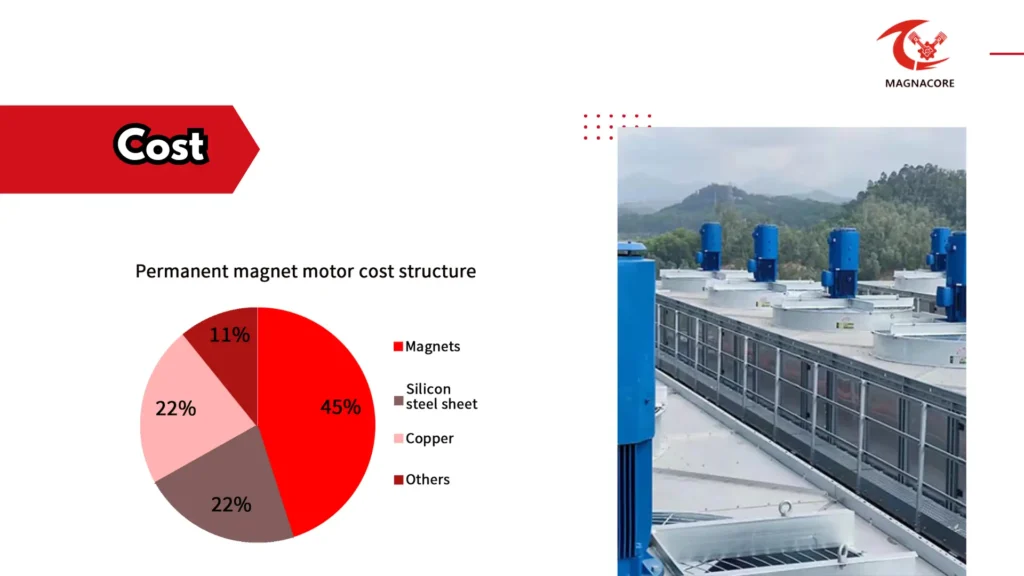

The materials play a key and significant role concerning Permanent Magnet AC Synchronous Motors (PMSMs) pricing.

Either the price of high-quality materials, such as rare-earth magnets and advanced alloys, increases along with the performance and life of the motor but is higher or decreases if low-grade materials are used; it will compromise the efficiency and longevity of the motor.

Manufacturing Processes

Highly complex manufacturing techniques directly affect pricing.

Precision machining and automated assembly, for instance, clearly enhance quality and efficiency; in particular, however, such quality raises cost and thus will equate to an additional cost for the manufacturer who opts for state-of-the-art production facilities.

As a result, it allows manufacturers to say their motors are more reliable, which can reflect a higher price tag.

Motor Size and Specifications

The motor’s size directly influences the price for which these electric motors are sold.

Those electric motors’ price rises with the extra material and manufacturing cost included, as long as the power ratings also go up and hence the size.

Certain specificities on external dimensions or very unique performance features tend to bring about more price.

Brand Reputation

It may be the single most important factor that a buyer looks at while pricing.

Well-known good brands have traditionally charged more because of the trust among consumers, in case nobody actually knows from where the brand is operating and what foreign-based company is backing it.

Brand less known might offer the lowest price just to ensure that they obtain business from that lowest price, but when it comes to performance and support, many of these brands fall.

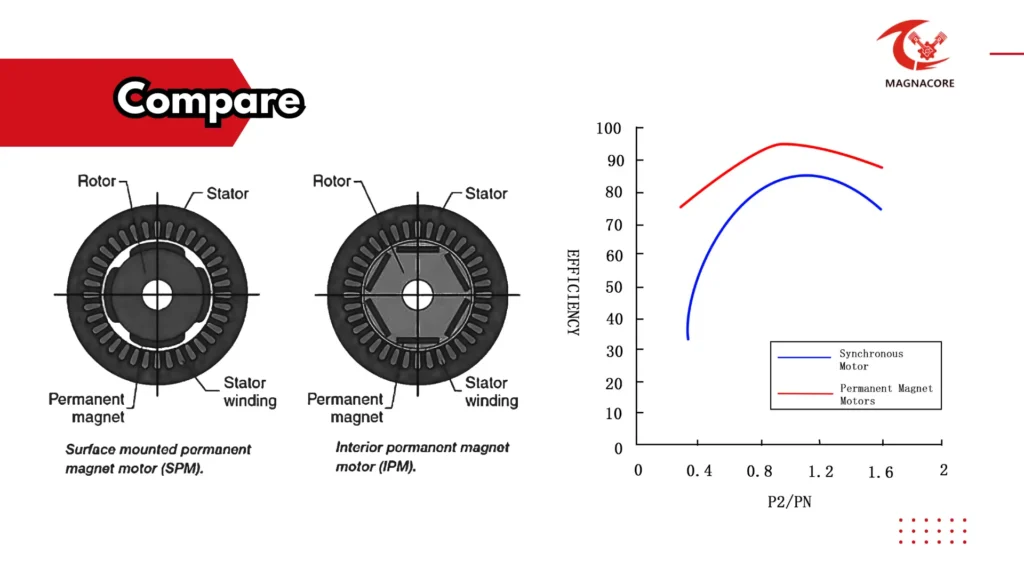

How Do Permanent Magnet Synchronous Motors Compare in Price to Other Motor Types?

Induction Motors vs. PMSMs

Induction motors compared to PMSM’s tend to attract a higher up-front cost.

But these motors are more efficient, which after some time, is expected to reduce overall operational cost.

As a result, companies have to set one against another in terms of an initial investment opposing long-term savings.

Brushless DC Motors vs. PMSMs

Indeed, brushless DC motors are priced in terms of PMSMs, but the choice is really of specific application needs.

Generally, PMSMs provide better torque and speed control, but there are definitely areas where BLDCs would be better suited.

All will depend on these points regarding what better suits your budget.

Cost-effectiveness Over Time

This higher initial investment in PMSMs will be up sitting when it comes to savings in energy bills and facility upkeep.

That gives a sense of the total expenditure in terms of purchasing and installation, maintenance, and energy savings-what energy is garnered from PMSMs that aren’t found inside other technologies.

Initial Investment vs. Long-term Savings

A majority of the decision related to the first expense ultimately disguises the fact of things.

Yet in spite of the higher initial associated costs for PMSMs, it’s worth a try, with a sustained return on the investment (ROI).

Ultimately, a business would have to signal how they understand the potential opportunity costs.

What Is the Average Price Range for Permanent Magnet Synchronous Motors?

Base-end Models

Mostly, low-end PMSMs will cost from a few hundred bucks to a couple of grand.

They cater to light-duty applications; hence, the full utilization of all the possible advantages seen in higher-end options might not be to the consumer’s advantage but is quite sure to meet all relevant needs for the buyer, being cautionary at this point.

Mid-Range Models

Mid-range PMSMs typically fall within a range of around $2,000-$5,000.

These types commonly offer a good trade-off balance between the price and the value of the performance in consideration of numerous industrial purposes.

They also tend to provide better features, good efficiency, and long warranties when compared to low ends.

Luxury Models

They can cost more than $ 5000 and sometimes run into tens of thousands in special applications.

They are suitable for very strict environments and usually deliver advanced technology.

These designs use excellent materials and a considerable customization array, suitable for particular applications.

Custom Solutions

Custom PMSMs can be fair, too expensive, depending on the exact requirements and features.

This may include unique sizes, especially power ratings, or customized components.

Companies looking for a unique solution should create a meeting with manufacturers to get the representative price for explicit needs.

How Can You Determine the Right Price for Your Needs?

Consideration of Application Requirements

Defining application requirements is the most important aspect to decide for what price range the Motors may fall.

Which includes the fuel load, the speeds it can bear, environmental humidity or temperature conditions.

So, getting feedback on your needs, it will be easy to get a motor that without becoming too much pricey, has good performance:

Performance Expectations

Define your expectations for the operation of a product you may need to set.

For instance, if yours is rather energy conservation or with precise controls, then buy the expensive PMMS.

On the other hand, for applications that do not have very big demands, you may consider a cheaper option.

Budget Considerations

Planning well your budget with regard to purchasing a PMMS is a very crucial tip.

Not only will prices be taken into consideration, but also knowing future expenses such as maintenance and power used.

Budgeting will help you make a wise financial decision.

What Are the Hidden Costs of Purchasing Permanent Magnet Synchronous Motors?

Setup Expense

Sorry to say, installation costs normally contribute the most to the PMSM total cost.

Sometimes engaging professional services is so necessary and can be dramatically expensive for many different reasons.

Don’t forget the cost of installation as a pattern considering the overall price to steer clear of surprises.

Energy Consumption

Energy consumption is a significant influencer on the total cost of ownership. PMSMs, though, usually are energy efficient.

The energy a motor consumes, therefore, significantly affects the overall cost of ownership.

Downtime and Productivity Impairment

The unplanned downtime caused by a motors failure results in large productivity losses.

The ideal motor accomplishes to avoid all these losses, results in the reduced cost labor time, lost revenue, and other costs associated with such kinds of downtimes caused by a motor failure.

How Do Discounts and Promotions Affect PMSM Pricing?

Seasonal Promotions

Most manufacturers and suppliers have seasonal sales, which lets some PSM price be reduced.

Checking into what these suppliers have done may help secure better deals, especially if you are not in a hurry to buy appliances.

Discounts on Larger Quantities

Typically, reduced per unit rates are what one can get while making bulk purchases.

When it concerns the purchase of several motors at once, it makes such provisions with some manufacturers or shops for good price discount.

This can be very cost efficient on large projects, making it worthwhile to consider in the point of planning.

Promotional Company

One of the more popular ways that most marketers are now saving on the costs of their equipment, materials, and many other requirements is to engage in such an event as a trade show, exhibition, or conference.

Nevertheless, some companies offer their products at a particular discount when accompanying promotional and often temporary events, but this is also mixed with many advantages like the series of newsletters that they make customer subscriptions into.

Trade-In Programs

The manufacturers sometimes conduct the trade-in programs among the buyers wherein the old machines could be exchanged against the new units or replacement discounts offered.

Profit can result from such a process as expensive costs can be covered by replacing some, if not all, of them.

What Should You Look for When Comparing Prices from Different Suppliers?

Warranties and Service Agreements

When looking at prices, it is very important to check the warranties and service agreements offered by the partner.

If the company offers a solid warranty, it can give peace of mind against failures in time-saving and investment.

Buyer Reports and Reviews

Do some research into customer reviews and testimonials to see whether other companies have bought the unit in the past and what they have to say about it.

This can help justify a slightly higher price due to positive feedback from buyers who have experienced the issue themselves.

Technological Maintenance and Resources

Whether or not a company provides the level of technical maintenance and resources is another critical factor to examine.

Access to content that details support staff and documentation makes a difference when one is trying to ware away at using the motor.

Transportation and Lead Time

To accept the various suppliers’ delivery times and lead times, one should be prepared to absolutely avoid the lowest price possible because even in such cases, the best-priced product comes with a price.

Delays in receiving the motor can seriously hamper operations. Time is gold, and it is of the essence.

How Can You Maximize Your Investment in Permanent Magnet Synchronous Motors?

Training and Education

Investment in training for operation and maintenance of PMSMs is a good idea for all the employees.

The equipment will last longer if the operator is aware of how even small problems can damage motors.

Doing Regular Maintenance

Regular maintenance of PMSMs can increase the life expectancy of machines.

Regular inspections and maintenance take care of periodic breakdown instead of preventing it and ensure that the machine runs with maximum efficiency.

Product Updation

Change modifications like the controllers or sensors in the system that could enhance the operation of the PMSMs.

Support a lean upgrade that will increase each feature and lead to more powerful outright performance more effectively than replacing the whole motor at once.

Monitoring of Performance Metrics

A factor that supervises performance metrics enables the user to come up with an idea of how well the PMSMs are being operated.

Collect efficiency, energy consumption, and a need for maintenance data so as to make good decisions about future investments and improvements to operations.

Conclusion

Understanding what lies behind the price of Permanent Magnet Synchronous Motors (PMSMs) is crucial whenever a company is planning to purchase one.

This price is determined by factors like material quality, processes of manufacturing units as well as the brand and reputation on the market.

PMSMs can require greater investment initially versus other types of motors.

But, in the longer run, the energy-efficient, cheaper maintenance, and higher performance of PMSM usually more than compensate for the initial costs.

The most significant factors contributing to popularity accuracy among suppliers are costs; however, the manufacturer can go beyond the item price more informally, warranties and customer support with time for delivery.

Times are fast changing in technology and market dynamics as such entail for investment in knowing more of the trends and revolutions forward.

Such investments lead to increased operational efficiencies and also cut down on long-term costs besides improving product quality, turning it into a smart move for any forward-thinking company.