The powerful combination of Permanent Magnet Motors (PMM’s) has surfaced in recent years covering most of the work done in various industries.

As costs related to operational procedures continue to rise among companies, knowing the advantages of PMMs is not only helpful but necessary.

This article looks at the inner workings of rotor type motors and what makes Permanent Magnet Motors better than the traditional ones and the role they play in the enhancement of energy consumption rates and the effectiveness of the respective systems.

Learn More:

Top 10 Permanent Magnet Synchronous Motor Manufacturers in China

Understanding Permanent Magnet Motors

What Are Permanent Magnet Motors?

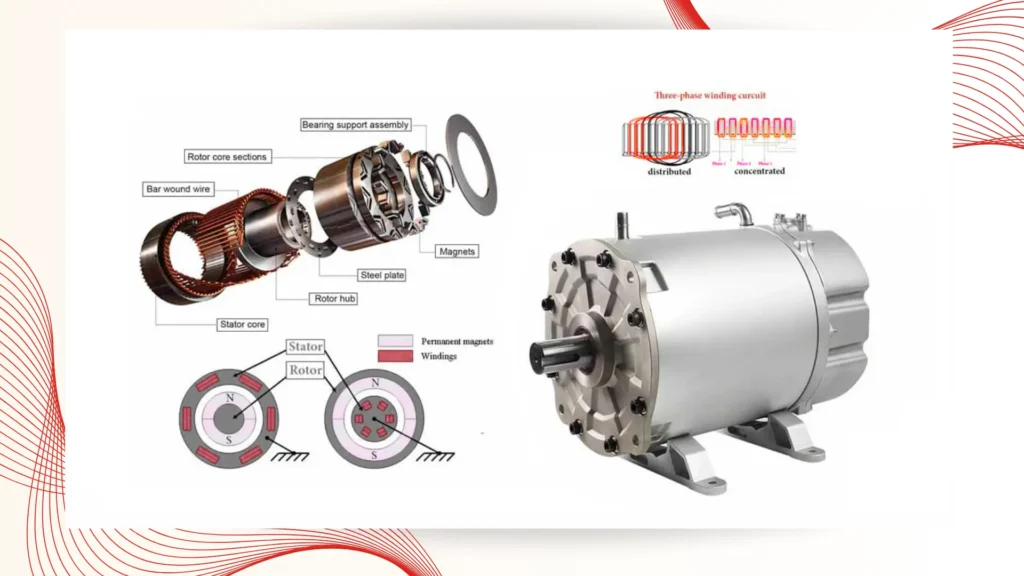

Permanent magnet electric motors are the electric motors that rely on permanent magnets to establish a magnetic field, as opposed to the traditional magnetically enhanced electric motors.

The difference in terms of design has the virtue of allowing the PMMs to be designed expending less space as well as achieving the goal of high efficiency at the same time.

It is noted that the permanent magnets are often built from neodymium materials and they are applied in the form of a compact structure which possesses strong permanent magnetism making these motors suitable for a wide range of applications.

How They Work

The operation of permanent magnet type motors relies on the magnetic fields generated by the rotor and stator interacting.

When the stator winding has an electric current, it develops a magnetic field which circumvolves.

At the same time, the stator winding, the one equipped with strips of coil profile and soft iron, plays a major role in the generation of the working flux which is used to drive that motor.

The flux interacts with the rotor with the permanent magnets attached within it, leading to the rotation of the rotor.

This enables mechanical energy to be generated through the speed torque product framework which can be put to various uses depending on the requirements at hand.

Types of Permanent Magnet Motors

Permanent magnet motors come in different shapes and sizes, and have different sets of advantages for various industrial applications:

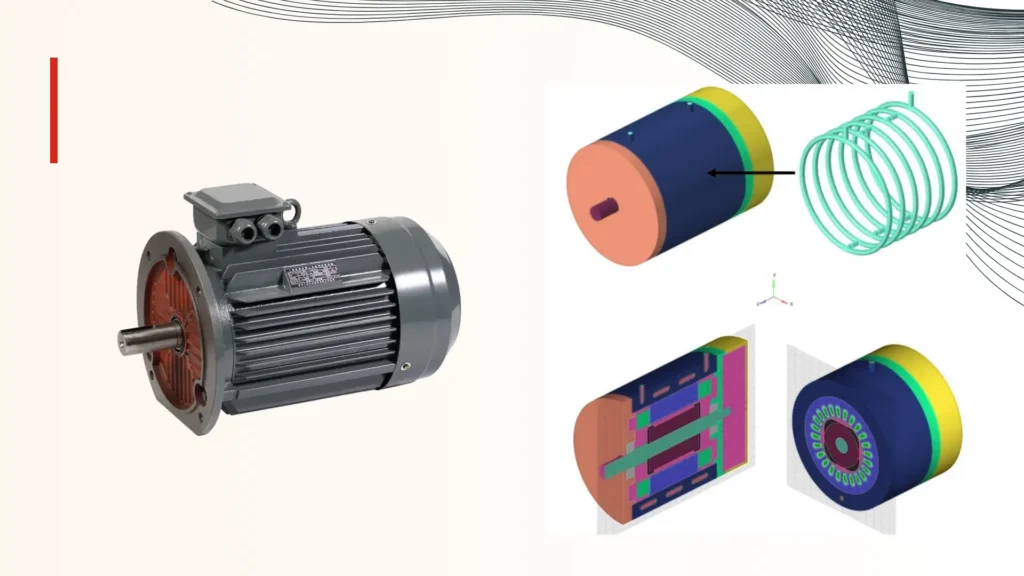

Synchronous Motors

These are motors in which the speed of rotation always remains constant as the flow supply frequency.

They are typically implemented in applications that require very precise control over motor speed such as artificial electronics and also conveyors.

Brushless DC Motors

These motors work better in high efficiency applications without having to use any brushes which reduces wear effect in maintenance.

They employ speed control and drive systems by means of electronic controllers.

This function makes them very popular among users using the electric vehicles as well as drones applications.

Switched Reluctance Motors

They are in fact very effectively exploited and reliable motors in industrial applications especially when harsh conditions is a major consideration.

Common examples are electric and hybrid vehicles where PMMs are utilized to facilitate both main propulsion as well as auxiliary operations like power steering or air conditioning.

Widespread Usage

Different industrial clusters have found a way to incorporate these technologies and components in quite a number of their operations:

Automotive

Such motors are being applied more and more in electromobiles, hybrids, where they are most often used as electricity suppliers, additionally playing their part in auxiliary operations, such as electro-hydraulic steering assist and air conditioning with or without heating.

Industrial Automation

PMMs provide motive to conveyors, pumps, and fans while functioning within factories, thereby helping reduce overall non-value adding operations and overall industrial productivity.

Consumer Electronics

In appliances as thick as a hard disk and even curiously thin, such technologies give these tools better performance, energy efficiency that prolongs their uses and satisfaction to users.

Renewable Energy

These motors take an important and irreplaceable place in wind and solar electrical power generator and follow the sun panels, due to their maximum possible effectiveness both in the energy recovery and in operational aspect.

Comparison with Traditional Motors

Differences in Uitilization

Advantage of the PMMs to the traditional induction motors is efficiency.

Achievable operational efficiency of the PMMs can go as high as 90%, resulting in significant saving of energy.

It is not only operational costs that is reduced by this efficiency but energy consumption as well that is very environmental friendly.

Maintenance Requirements

One thing that PMMs do not have in their tool box include brushes which help in their easier operations as compared to the other motors.

This less frequent interventions help to minimize the duration and the extent of interruptions to the production processes, hence PMM are a better alternative for the applications requiring the highest level of dependability.

Initial Costs vs. Long-term Savings

Sometimes the upfront payment for PMMs could be greater in comparison to the use of traditional motors but the costs saved on energy and rehabilitation mostly justifies the initial expenditure. In energy intensive industries in particular, businesses can anticipate a good payback over an extended period.

Performance Metrics

PMMs perform very well when subjected to different performance evaluation criteria such as torque density and rate control.

They are designed to give quite a stable power output with the possibility of varying load.

There is marked expectation for high functioning level within a perfect operating environment in activities where adherence to a high level of specification is required calcification.

Why Use Permanent Magnet Motors?

Enhancing Performance

The intensification of widespread distribution and application of PMMs in all industries is due to their high performance.

These are motors, which manage to convert the electrical energy and tries to minimize the amount of waste has been impacted to mechanical energy.

This but represents its efficiency in you share some resemblance with some applications where the cost of energy is the predominant factor and energy efficiency is crucial.

Providing Efficient Solutions

There is less energy consumption attributed to the implementation of PMM, which simply allows to overcome resistive losses rather than amplifying them.

This puts benefits that are used towards the costs of energy and carbon reduction and thereby, turning PMMS into an eco-friendly technology.

Cost Savings and Cost-Effectiveness

Besides their optimized utilization and low-performance losses, PMMs bring about additional benefits through reduced wear and tear which in turn lower associated costs of operations.

Some of these funds might also be used to finance expansion strategies hence passing the profit margins.

Durability and Trust

ned magnet motors are long lasting and in many a case, they are far much better than the available traditional motors.

In most cases especially involving critical applications, this long lasting nature ensures that the drive system remains reliable, hence reducing the cost of frequent maintenance and replacement.

Environmental Impact

Greenhouse Gas Reduction

One of the benefits that PMMs give is lower carbon footprint in most cases by bringing up energy efficiency.

This is of increasing importance to the organisations as they strive to achieve self-sustaining practices and also due to legislations on the environment.

Saving Energy

Adopting PMMs assists the bigger energy saving mission. Investment in them implies that it is possible to apply less power as concern for the output takes center stage in industries.

This in the long Run saves energy and hence makes activities more sustainable.

Regulation Compliance

Such measures will come as a relief since they will demand that more energy is conserved which would mean less costs for some industries like using water for industrial processes.

Yet, legal requirements with regards to energy efficiency may also be increased.

Contributing to Sustainability

The popularity of PMMs equates with the alleviating concerns of climate change all over the world. Introducing such conduct is especially crucial at this time, when global warming due to the announced global industrial development is causing climate change due to the uncontrolled depletion of various resources.

Cost Savings Over Time

Lower Energy Bills

The high economy of work accomplished by PMMs equals less energy use which in consequence translates to money savings at the business end.

For some establishments, this alleviation may significantly exceed their marketing budgets, allowing them to spend on other necessary areas instead.

Oxed Costs

Lesser moving parts and no brushes is an advantage since one cannot bear the burden of charges in the first place.

This earns people’s trust and also helps cut the amount of money and other factor(s) which are spent on the system up keeping, leaving a lot of work for the leadership and the other staff.

Reserved Longevity

The durability of PMMs is economically beneficial to the users as it promotes longevity of use.

Companies decrease the number of substitutions, there by interruptions in the production process stabilization of which is always a plus.

Capital Recovery After Installation

The above financial aspects of PMMs often amount to high rates of capital recovery.

Einsi’s PMMs for instance due to their ability to save on the productive life span have certain net advantages over the other conventional technologies.

Key Industries Benefiting from Permanent Magnet Motors

Retail

Looking at the retail sector, PMMs are critical for electric and hybrid automobiles in order to ensure a good range and performance – the efficiency of these helps a lot.

The reason why the ‘dealers’ are interested in hybrid cars is because they stand out fr om others.

However, the development of PMMs will affect the different sectors, with the automobile and transport sectors being two of the most affected.

Telecom Services

The use of PMMs is equally important in the field of telecommunications because turbines generate electricity and this kind generation of power is used in telephone base stations.

Moreover, the power consumption of such stations is also reduced in because of the efficiency provided to generators which in turn generate electricity for equipment.

Travel

In general tenders for solar, wind, etc installs require PMMs to be energy generated with a target – typically 95% of the energy generated.

However services that have stringent energy or power requirements but do not utilize their systems substantially for extended periods of time will find themselves trading and carrying load on advance and decline.

Pharmaceuticals

PMMS technique is applied in the pharmaceutical, biopharmaceutical and medicinal sector at different levels, in the evaluation of medicinal products, particularly their pharmacokinetic and pharmacodynamic characteristics in vivo. In vivo drug testing requires the use of PMMS, which is in question at the initial stage of the study.

Choosing the Right Permanent Magnet Motor

Critical Points to Bear in Representation

Point I is when choosing a gradient, you have to also look at what the output is; availability given conditions of torque, speed, and climate.

Understanding what the intended use of the motor will be will affect your choice.

Migration and Model and its Parameters

The correct sizing and parameters of the model must be used to achieve the best efficiency.

Using a motor which is very small is not acceptable, yet using one which is too big consumes more energy.

Suppliers Appraisal

It is critical to select the sellers very carefully in order to ensure that credit and dependability are maintained.

Dealers who have a reputation of supplying quality rotary motors as well as a satisfaction assurance are the best.

Additional Charging Elements

Various manufactures have the capability to include additional features to the PMSM in order to adapt it to the specific areas of application.

These features may involve alternations of the frame size, power output, and various requirements which dictate the motor to be manufactured to the certain peculiarities.

Conclusion

Each part of the permanent magnetic motors is taking advantage of them in terms of benefits and this is because they are very economical.

Because they have a very low energy consumption and low maintenance they guarantee a long service life for many applications.

It is worth organizations to research more on permanent magnet motors for the sake of improvement in their operations for better productivity, environmental-friendliness and resource economization.

The upside to the use of PMMs is that it will have an integrative impact on the cost structure of the organization as well as the image of the organization.

Eventually, for those of you who wish to change from the already obsolete motor technology, it is advisable to find out more on PMMs and even contact the vendors. Knowing these things enables the companies in optimizing operations.