Permanent magnet motors are electric motors that generate magnetic fields by using permanent magnets instead of the electromagnetic coils used in all traditional motors.

PM motors are known for both their high efficiency and compact design and have become an increasing presence in a wide variety of applications, from industrial machinery to consumer electronics.

Changes in modern fast-paced industrial world require much more of effective machines that can be relied upon.

The increased productivity brought by permanent magnet motors comes at a very low energy consumption.

The fact that these motors work at the highest levels of efficiency turns into smaller operational costs and a smaller footprint on the environment, which is an indispensable consideration in the new sustainability goals.

High-performance permanent magnet motors are designed for very superior efficiency, torque, and rapid response.

These motors have sophisticated design features and expensive materials, hence their application for precise accuracy and reliability.

Continuous innovations will mark these motors at par-high standards of performance and efficiency.

Key Advantages of Permanent Magnet Motors

Energy Efficiency

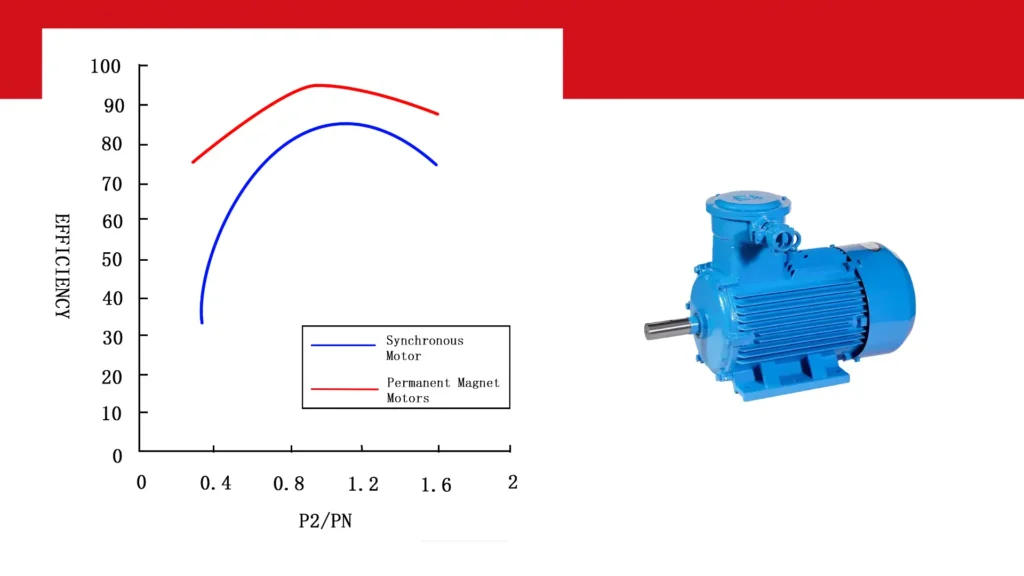

One of the main features of permanent magnet motors is energy efficiency.

In fact, efficiency ratings of more than 90% can be achieved with such motors, leading to significant energy savings when comparing their operations with traditional motors.

This not only helps in cutting electricity bills but also minimizes the overall carbon footprint of operations.

Compact Design

The compact inherent design of PM motors enables flexible installation options.

Moving towards smaller sizes allows manufacturers to save space in their machinery designs and makes integration into existing systems more easily realized.

In addition to that, compactness is better in applications where every inch is critical.

Low Maintenance Requirements

Permanent magnet motors require less maintenance compared to their traditional counterparts.

They are more reliable due to fewer movable parts and no brushes to wear out.

With longevity, most people require less downtime and much lower operational interruptions on these motors, which makes them a preferred choice for many industries.

And More:

Applications of High-Performance Permanent Magnet Motors in Industry

Applications of Permanent Magnet Motors

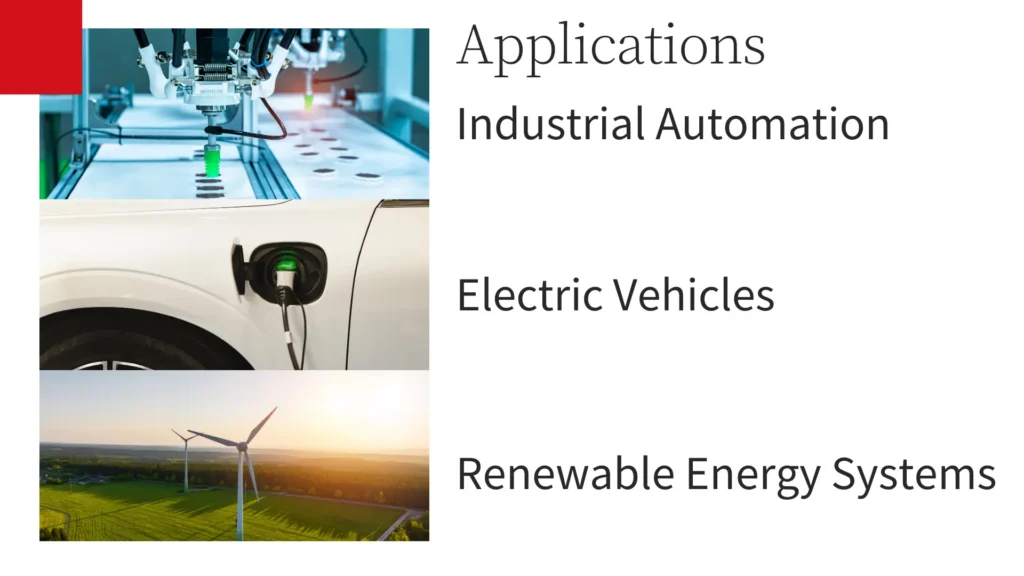

Industrial Automation

In industrial automation, the fast emerging area of application of PM motors is robotics, automated conveyor systems, and the highly flexible automated assembly line.

High torque and precise control invariably assure smooth and efficient operations, improving productivity while shortening the cycle times.

Electric Vehicles

The burgeoning demand for high-performance permanent magnet motors has been largely driven by the rise of electric vehicles (EVs).

Such motors are power and efficiency suitable for long driving ranges and faster accelerations of such vehicles.

Additionally, the lightweight and compact nature of these motors dovetails well into the automotive industry’s idea of efficiency.

Renewable Energy Systems

PM motors are an essential part of renewable energy systems.

They act mainly in wind turbines and solar tracking systems.

Their efficiency and reliability contributed significantly to maximizing energy output and, therefore, a key component in shifting to sustainable energy becoming increasingly crucial.

Advanced Technologies in Motor Design

Exceptional Magnetic Materials

The trend of high-performance PM motors is enhanced by much advanced magnetic materials like neodymium and samarium-cobalt that provide much stronger magnetic fields that drive improvements in efficiency and performance and allow higher power output using smaller versions.

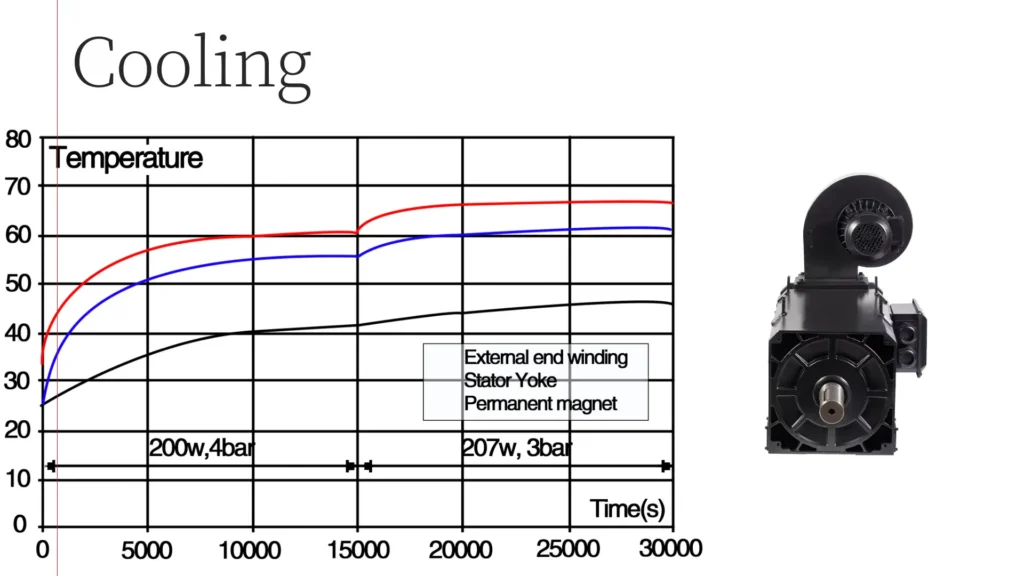

Innovative Methods of Cooling

Some of these advanced cooling technologies require maintenance to ensure the PM motors work optimally, such as preventing overheating if the motor is heavily loaded.

This allows the device to keep on working properly for a longer time.

Smart Functions

These control capabilities generally comprise sensor feedback and programmable controls, features that many modern PM motors are now including.

On the other hand, they yield high flexibility for various applications, allowing accurately controlled speed and torque for unmatched system performance.

Performance Metrics to Consider

Torque and Power Output

Torque and power outputs are very important parameters in choosing a permanent magnet motor.

These high-performance models have excellent torque characteristics, enabling the motors to deliver better performance in demanding applications.

Understanding these metrics is beneficial while selecting motors for different requirements.

Speed Range and Control

Another factor to consider when selecting a PM motor is the speed range.

High-performance motors are capable of quickly extending to the speed range while maintaining accurate control suitable for a variety of applications.

Such features are essential for industries that have a requirement for variable speed operations.

Lifetime and Reliability

These are the major aspects about which one has to be sure in motor selection.

The top-quality permanent magnet motors are specially designed for reliability; they last longer than conventional motors.

Because of such construction and the low-maintenance requirements, they are even better than others were as reliable in such harsh environments.

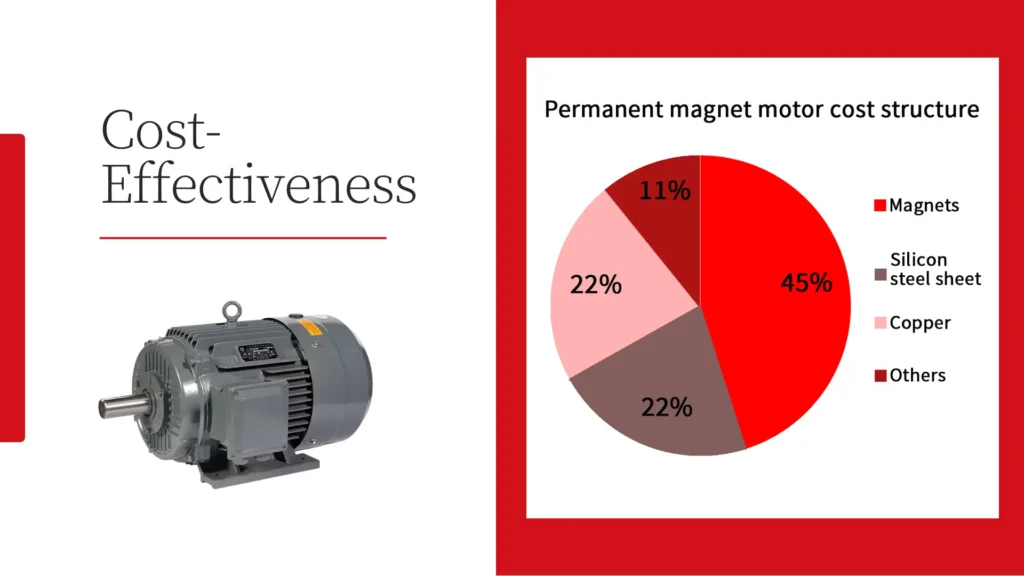

Cost-Effectiveness of High-Performance Motors

Initial Investment VS Subsequent Savings

Although the initial cost of employing high-performance permanent magnet motors is more than traditional alternatives, it brings in huge amounts of saving in the long run.

Its consumption of energy and maintenance usually returns earlier cash into the investee’s pockets, thus making it a lucrative financial option.

Money Return Ratio

Calculating the Return on Investment (ROI) for PM motors will involve energy savings and maintenance savings plus an element for increased productivity.

Many companies discover that overall efficiency improvements and motors being more reliable yield a positive ROI very quickly past initial costs.

Comparison with Conventional Motors

Comparative study of PM motors and conventional motors shows that the two are indeed different in terms of performance and efficiency.

Despite the attractiveness of low upfront costs associated with conventional motors, the long – term benefits such as energy savings and reduced maintenance usually make PM motors worth the initial price differential.

Environmental Impact and Sustainability

Improved Energy Efficiency

All these factors give permanent magnet motors a lower carbon footprint due to an energy-efficient operation.

Using less power, companies can meet their sustainability goals and adhere to regulations with a more accountable option for modern business.

Recycling and Material Sustainability

Sustainable procurement of the resources components in PM motors such as rare earth magnets is slowly but surely spreading.

Hence, recovery of these resources is another pathway through newly developed recycling technologies which promote environmental sustainability and thus reduce waste.

Conformance to Environmental Standards

Most of the following high-performance PM motors are built to meet stringent environmental standards so as not to bring penalties into any organization but at the same time add to it the perception as an environment-friendly organization.

Choosing the Right Manufacturer

Reputation and Experience

There is no concern like that of reputation and industry experience when choosing a manufacturer for permanent magnet motors.

There is always some associated confidence in investment for consumers by a manufacturer whose experience suggests they have produced reliable, high-quality motors over time.

Quality Assurance Process

Quality assurance for motor manufacturing at a reputable manufacturer provides a very rigorous testing and quality control assurance all of which may give guarantee benefits.

This ultimately translates into performance and reliability for end users.

Customer Support and Services

Customer services add to the benefits inherent in such manufacturers when it comes to post-purchase service problems, installation assistance, and troubleshooting.

Conclusion

High-performance permanent magnet motors provide high efficiency, small size and very low maintenance in operation.

Applications of these motors are so many that they can be qualified as the versatile performers for modern machinery needs.

Technology continuous changes dynamic to place the future of permanent magnet motors at a promising end. Innovations in materials and designs are likely to produce an even better-performing array of applications proving their future role in the next generation of industrial solutions.

If you are contemplating plans for upgrading gear or considering avenues for better motor systems, high-performance permanent magnet motors from China would well serve the purpose.

Contact a reputable manufacturer today so you can know more about the benefits of using these advanced motors in your operations.