Today’s industrial sector is seeing rise of Permanent Magnet Synchronous Motors (PMSM). PMSM are enhancing efficiency.

They are empowering performance in various applications. With their increasing favoritism many businesses are heading to China for manufacturing options. This work is a scrutiny of what PMSMs are.

It delves into their benefits. It also discusses why Chinese manufacturers are top choice for many buyers.

Learn More:

Key Features of Permanent Magnet Synchronous Motors (PMSMs)

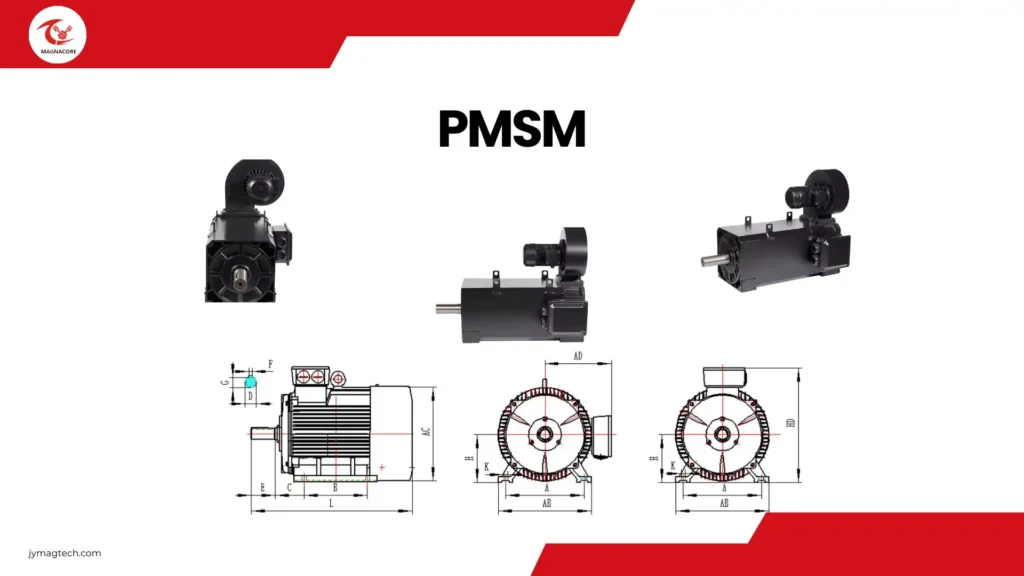

What is PMSM?

Definition of PMSM

This motor utilizes permanent magnets to induce a magnetic field.

This design enables a PMSM to achieve precise control of speed and torque. PMSM motors are suitable for a variety of applications.

Unlike traditional induction motors, PMSMs do not need an external power source to create a magnetic field.

This results in improved efficiency.

Main components of a PMSM include rotor, stator and power supply. Each plays a vital role in the overall performance.

Advantages of PMSM

And More:

The Benefits of PMSM: Transforming Efficiency in Electric Motor Technology

Energy Efficiency Benefits

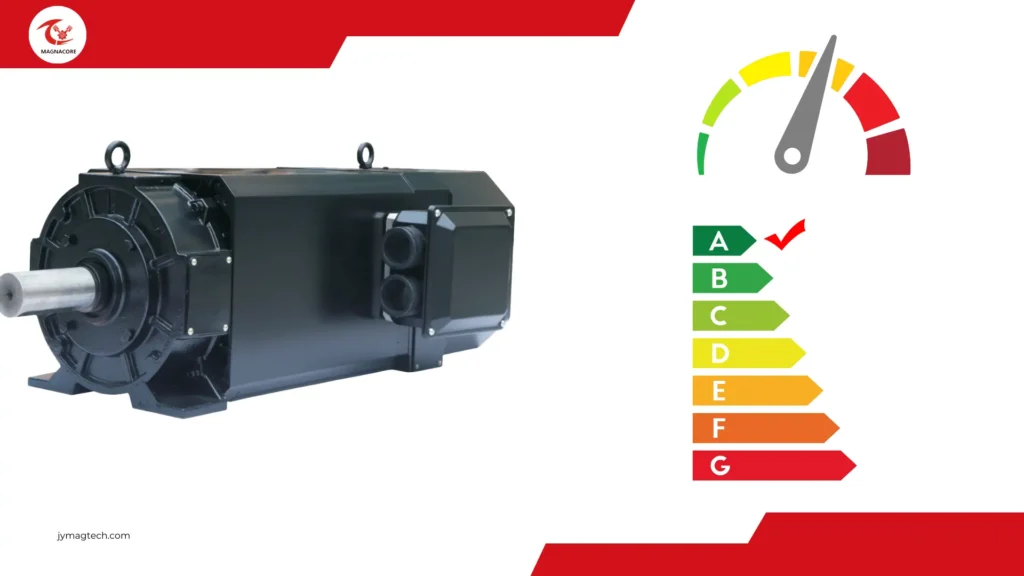

These motors flaunt high efficiency often passing 90%. This leads to lower energy use. It also reduces electricity costs.

High Torque and Speed Capabilities

Permanent Magnet Synchronous Motors (PMSMs) boast high torque. They do this at lower speeds. This makes them perfect for scenarios that need rapid acceleration or deceleration.

Reduced Noise and Vibration Levels

The smoother operating PMSMs cause a notable reduction in noise. They also lower vibration. These factors enhance comfort levels.

Thus they are useful in applications with special attention to comfort. Take electric vehicles as an example. They also find use in HVAC systems.

Applications of PMSM

And More:

Exploring the Versatile Applications of Permanent Magnet Synchronous Motors (PMSM)

Use in Electric Vehicles

Automotive industry banks on PMSMs. They are efficient and have high performance. This leads to longer battery life. It also brings a better driving experience.

Role in Industrial Automation

PMSMs get used in many factories. Use is in robotic systems and conveyor belts. They offer precise control.

Applications in HVAC Systems

In heating ventilation and air conditioning systems PMSMs provide variable speed control. They contribute to energy savings.

Why Choose PMSM Manufacturers in China?

Overview of Manufacturing Landscape

Scale and Diversity of Manufacturers

A wide range of manufacturers exist in China. These range from small workshops to large-scale factories.

They can produce PMSMs for a variety of needs. China’s manufacturing capabilities thus span the entire spectrum.

Regional Specialization in China

There are parts of China that specialize in certain types of motors. They harness local knowledge and resources. This results in increased production efficiency.

Innovation and Technology Adoption

Manufacturers in China have a reputation for quickly adopting new technology. They keep improving their processes and products. This is to meet the highest global standards.

Cost-Effectiveness

Competitive Pricing Models

Labor costs are lower in China. Manufacturing in bulk is possible there. Often PMSMs from China are more affordable. They are compared to those from other countries.

Economic Advantages of Purchasing from China

Businesses are able to capitalize on cost benefits related to manufacturing in China. This practice allows for improved margins of profit.

Bulk Purchasing Perks

Discounts can be availed by many manufacturers. This offer is for bulk orders. Larger companies can benefit. They need to scale up their operations.

Quality Assurance

Compliance with International Standards and Certifications

Many reputable manufacturers adhere to international standards. They often comply with ISO 9001.

This compliance ensures that manufactured goods achieve high quality and safe use benchmarks.

Quality Assurance Processes in Manufacturing

Stringent testing and controls are instituted. They are used throughout the manufacturing process. This practice aims to reduce defects. It also ensures product reliability.

The Status of Chinese Manufacturers

Numerous producers have cultivated a robust reputation.

These manufacturers received affirmative reactions from overseas patrons. This interaction bolsters their standing in the industry.

Key Benefits of PMSM

Energy Efficiency

In-Depth Examination of Energy Savings

Operating at high efficiency levels PMSMs can considerably trim energy costs for businesses. This renders them an appealing investment.

Potential Long-Term Cost Implications for Enterprises

The up-front investment in PMSMs often exhibits returns in the long haul. This is due to the reduced energy bills and low maintenance costs.

Environmental Effects from Using PMSMs

Less energy consumption leads to diminished greenhouse gas emissions. This dovetails with worldwide sustainability goals.

High Performance

Characteristics of Torque and Speed

PMSMs offer high torque at low speeds. This serves applications needing quick responsiveness.

Consistency Under Varying Loads

Unlike other motor types permanent magnet synchronous motors or PMSMs maintain performance.

This remains the case even as load conditions change. This ensures reliability especially in critical operations.

Suitability for Precision Applications

Ideal for precision applications PMSMs exercise precise control. They control speed and torque.

Robotics and CNC machines are examples of such applications. They require high accuracy.

Low Maintenance

Comparison with Traditional Motors

Permanent magnet synchronous motors require less maintenance. This is in comparison to traditional induction motors. Traditional motors often suffer from wear.

Impact on Operational Downtime

Reduction in maintenance needs brings benefits. It leads to lower operational downtime. This enables businesses to maintain productivity.

Long-Term Reliability and Lifespan

Design of permanent magnet synchronous motors is robust. This durability contributes to their longevity. PMSMs are thus a cost-effective choice over time.

Versatility

Range of Sizes and Configurations

They come in various sizes. They are also offered in varied configurations. The aim is to meet very particular needs.

Customization Options Available

Several manufacturers give option for customization. It is given to satisfy specific needs.

There is a guarantee. It assures that right solution can be found. It is for the needs of their businesses.

Applications Across Different Industries

They illustrate these applications. Permanent Magnet Synchronous Motors or PMSMs have extensive applications.

They are found in different sectors. These sectors include healthcare and manufacturing. The motors illustrate their effectiveness. Their versatility is also demonstrated.

How to Choose the Right PMSM Manufacturer

Certifications and Standards

Significance of Global Accreditations

Accreditations are integral. They ascertain that manufacturers meet set quality and safety standards. This provides assurance to consumers.

Key Certifications to Observe

Observe for ISO accreditations. Also, seek CE markings. Additionally take note of other industry standards exemplifying a dedication to quality.

Implications on Product Quality and Dependability

Certified manufacturers are more liable to generate dependable products. This reduces the chances of failures and resultant costs.

Experience and Expertise

Evaluation of Manufacturer Skill in PMSM Production

A manufacturer with vast experience is more prone to produce premium motors. These motors meet customer specifications.

Significance of Industry Awareness

Manufacturers with in-depth understanding of their industry have an edge. They can predict market trends better. Also, they can understand customer needs more accurately. This leads to creative answers.

Case Studies from Previous Customers

Encouraging feedback and tales of triumph from past clients enrich the understanding.

They give insights into a manufacturer’s trustworthiness. They also shed light on their quality.

Customer Support and Service

Importance of After-Sales Service

A dependable after-sales assistance can expedite resolution of issues. It yields minimal interruptions to operations. Reliable after-sales support can help address issues promptly. This results in the least disturbance to operating procedures. Technicalities can be difficult.

Technical Support Availability.

Manufacturers who provide robust technical backing are beneficial. They help with the setup. They can aid in identifying and resolving problems. Also they assist with equipment upkeep.

Response Times and Communication Effectiveness.

Assess how quick manufacturers are in replying to questions. High-quality partnership needs good communication. It demands an effective partnership as well.

Production Capabilities

Assessing Manufacturing Capacity.

You must ascertain whether manufacturer can fulfill your volume needs. This is majorly important for large orders.

Flexibility in Order Sizes and Customization.

Manufacturers capable of handling small and large orders are valuable. As are those who can address customization requests. These manufacturers offer extensive flexibility.

Technology and Equipment Used in Production.

Utilization of advanced technology can elevate production efficiency. The implementation of modern equipment can do this as well. It can boost product quality.

Trends in PMSM Manufacturing

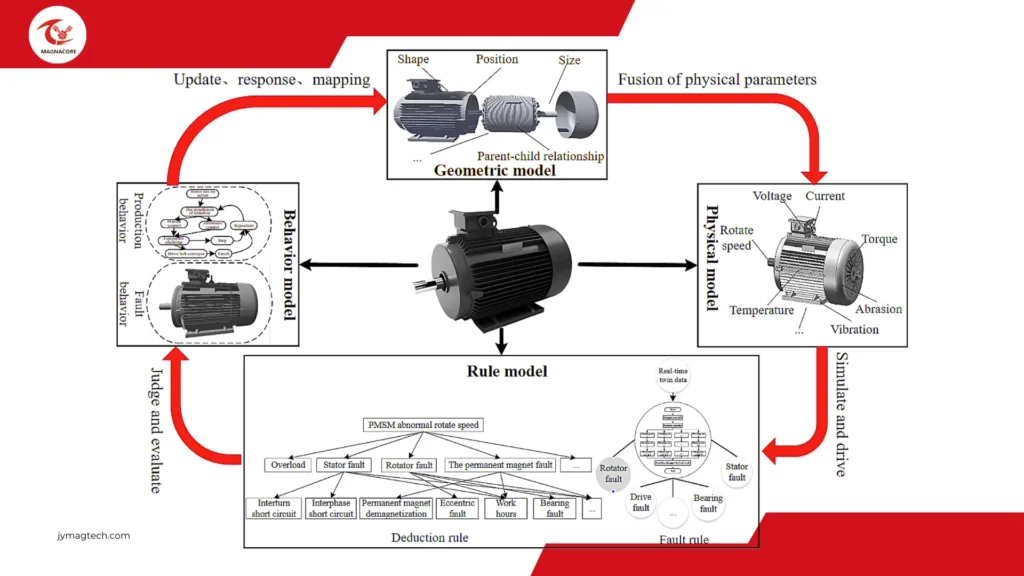

Technological Advancements

Innovations PMSM Design Production

Novel materials are in creation. Also new design techniques. The aim is to elevate performance.

These innovations are exciting. They signal a new age. An age of heightened efficiency in PMSM design. An age of reduced cost in PMSM manufacture. Truly a time of promise and possibility.

Integration Smart Technologies

Incorporation IoT and smart technologies permit better monitoring. Control of PMSMs is enhanced. This leads to improved efficiency.

Future Trends in Motor Technology

To ensure competitiveness, stay abreast of developing trends. For example there are more compact motors. They are efficient as well.

These trends are important. As we compete in the market, we must not lag behind. It is paramount for success to stay informed. We must keep an eye on these trends.

Market Demand

Growing Industries Driving Demand for PMSMs

Electric vehicles industries in growing state. Renewable energy on the rise. Automation industries are budding too. These are the industries driving demand for PMSMs.

Regional Variations in Market Needs

Distinct regions may have certain requirements. These are based on local industries. These specific requirements impact types of PMSMs in demand.

Impacts on PMSMs in demand are influenced by regional requirements.

Future Market Trends Prediction

Market analysts predict continuance in PMSM growth. This is driven by technology advancements. As well as by growing demands in energy efficiency.

Sustainability Practices

Eco-Friendly Manufacturing Processes

Many producers are now taking up greener methods. The goal is to reduce impact on the environment during production.

Impact of PMSMs on Reducing Carbon Footprints

Businesses can drastically cut energy use. They can also lessen carbon emissions by using PMSMs.

Corporate Responsibility Among Manufacturers

Manufacturers that push sustainability forward can enhance their reputation. They also appeal to consumers conscious of environment.

Challenges in PMSM Manufacturing

Supply Chain Issues

Common Supply Chain Disruptions

Global events can lead to turmoil in supply chains. They can impact availability of raw materials and parts. This in turn affects production schedules.

Strategies for Minimizing Risks

Suppliers need diversification. Inventory needs good management. Both of these can help. They can help mitigate supply chain risks. They can also ensure operations continue without interruption.

Importance of Local Sourcing

Creating connections with local suppliers augments resilience. It also reduces dependence on global supply chains.

Quality Control Challenges

Quality Control Problems

Maintaining Uniformity in Production

Strive for stringent quality control. It is essential. You produce dependable PMSMs. You can’t overlook it.

Dealing with Defects and Returns

Manufacturers. They need to have processes. Processes in place for quick defect addressing. They have to manage returns. Why? To sustain customer satisfaction.

Excellence in Quality Assurance Practices

Perform audits regularly. Train employees. This can enhance quality assurance. It can also improve production standards overall.

Competition in the Market

Examination of Global Competition

Worldwide companies engage in competition. They aim to manufacture high-quality PMSMs. This competition propels innovation. It also enhances standards.

Differentiation Strategies

Manufacturers must identify ways to differentiate. This can be done through superior customer service. It is also possible through unique product features.

Importance of Innovation in Competitive Stance

Continuous innovation is of utmost importance. For manufacturers to retain relevance. They must meet the needs of the evolving market.

Conclusion

Investment in PMSM from reputable manufacturers in China results in considerable benefits.

This is especially for your business. PMSMs are chosen for their energy efficiency. They are robust in their performance. They have low maintenance needs. Also they are versatile.

They make an excellent choice. Various applications could benefit from them. As one navigates various choices these factors should be part of the consideration.

When selecting the manufacturer it’s important to keep these factors in mind. The final aim is to align the manufacturer with your specific needs.