Choosing the right rare earth permanent magnet synchronous (PMS) motor supplier is crucial for performance, reliability, and long-term cost savings.

However, not all suppliers meet industry standards, and selecting the wrong one can lead to costly delays, subpar products, or compliance issues.

Here are five key red flags to watch out for when evaluating potential suppliers.

Does the Supplier Lack Proper Certifications?

Missing ISO or Industry-Specific Certifications

A reputable supplier should possess essential certifications such as ISO 9001 for Quality Management and ISO 14001 for Environmental Management.

These certifications demonstrate a commitment to maintaining high-quality standards and ensuring environmentally responsible practices.

If a supplier is unable to provide these certifications, it raises concerns about the reliability and consistency of their manufacturing processes.

Lack of certification may indicate that the supplier does not adhere to best practices or quality assurance protocols, which can lead to inferior products and increased risks for your operations.

No Compliance with International Standards (IEC, CE, RoHS)

Compliance with international standards is crucial for ensuring the safety and efficiency of rare earth Permanent Magnet Synchronous (PMS) motors. Suppliers should meet IEC (International Electrotechnical Commission) standards, as well as provide CE marking and RoHS compliance for their products.

These certifications indicate that the motors have been tested and deemed safe for use in various applications.

If a supplier cannot provide evidence of compliance, it raises red flags about the quality of materials used and the overall reliability of the motors.

Avoiding suppliers lacking these credentials is essential for safeguarding your investments and ensuring compliance with regulatory requirements.

Incomplete or Vague Documentation

Trustworthy suppliers should be transparent and readily provide comprehensive documentation, including test reports, material certifications, and compliance documents.

If a supplier hesitates to furnish this information or provides incomplete or vague paperwork, it is a major warning sign. Such behavior may indicate a lack of accountability and commitment to quality.

Thorough documentation is essential for verifying that the products meet industry standards and specifications.

Suppliers who are unwilling or unable to provide clear documentation may be hiding issues that could lead to performance problems down the line.

And More:

Avoiding Counterfeits: How to Verify Authenticity of Rare Earth Magnets

Are Their Prices Suspiciously Low?

Unrealistically Cheap Compared to Market Rates

While everyone appreciates a good deal, prices that are significantly lower than market rates should raise caution.

Unrealistically cheap prices may suggest that the supplier is cutting corners, potentially using low-quality magnets, inferior copper windings, or even counterfeit components.

High-performance PMS motors require precision engineering and adherence to strict quality standards.

Opting for cheaper alternatives often results in poor performance, premature failures, and increased long-term costs due to repairs or replacements.

Assessing the pricing relative to industry standards is essential for ensuring the quality and reliability of the motors.

Hidden Costs in Shipping or Customs

Some suppliers may present low upfront prices to attract buyers but later introduce hidden costs related to shipping, packaging, export duties, or customs clearance.

These unexpected fees can significantly increase the total cost of the purchase, undermining any initial savings. It is crucial to request a detailed breakdown of all associated costs before committing to a purchase.

Understanding the full financial implications ensures that you can make informed decisions and avoid unpleasant surprises that could affect your budget and project timelines.

No Warranty or Guarantee

A legitimate supplier should offer a warranty of at least 1-2 years on their products, demonstrating confidence in the quality and reliability of what they sell.

If a supplier refuses to provide a warranty or offers vague terms, it raises concerns about their commitment to product quality.

A warranty is an essential safety net for buyers, protecting them against defects and failures. Suppliers that do not stand behind their products may be indicative of poor manufacturing practices or low-quality components, making it wise to seek alternatives that offer clearer guarantees.

Do They Have Poor Communication and Responsiveness?

Slow or Inconsistent Replies

Reliable suppliers are characterized by their prompt and consistent communication. If a supplier takes days to respond to basic inquiries, it raises concerns about their professionalism and operational efficiency.

Slow responses may indicate underlying logistical issues or a lack of resources to manage customer inquiries effectively. In a competitive market, timely communication is essential for maintaining workflow and addressing urgent needs.

Suppliers who demonstrate poor responsiveness may not prioritize customer service, which can lead to frustrations and complications down the line.

Unclear Technical Support

A good supplier should provide clear and detailed technical support, including comprehensive motor specifications, datasheets, and engineering assistance.

If a supplier struggles to explain technical aspects of their products or provides vague information, it suggests a lack of understanding of their own offerings.

This lack of clarity can create confusion for buyers and hinder the decision-making process.

Effective technical support is critical for ensuring that customers can select the right products for their applications and fully utilize the capabilities of the motors they purchase.

No Local or Reliable After-Sales Service

In the event of a problem with a motor, having accessible and reliable after-sales service is essential.

Suppliers who lack local contacts or have a reputation for slow response times can leave customers stranded with malfunctioning equipment. This lack of support can lead to extended downtimes and increased operational costs.

A trustworthy supplier should have a clear after-sales service plan, including local representatives or support teams that can respond quickly to issues.

Ensuring that effective support is available when needed is crucial for maintaining productivity and minimizing disruptions.

Is Their Production Capacity Unverifiable?

No Factory Audits or Virtual Tours

Established suppliers typically welcome factory inspections, whether in-person or virtual, to demonstrate their production capabilities and quality control processes.

If a supplier refuses to allow factory audits, it raises red flags about their operations and may indicate that they are outsourcing production to unreliable third parties.

Transparency in manufacturing processes is essential for building trust and ensuring that products meet quality standards.

Suppliers who are unwilling to provide access to their facilities may be hiding issues that could affect product reliability.

Vague Lead Times and Frequent Delays

Consistent delays in production and vague lead times are indicators of poor inventory management and operational inefficiencies.

Suppliers who frequently miss deadlines may be overpromising their capabilities, which can result in significant disruptions for buyers relying on timely deliveries.

It is prudent to ask for detailed production schedules and past delivery records to assess a supplier’s reliability.

Understanding their ability to meet deadlines is crucial for planning projects and ensuring that operations run smoothly without unexpected interruptions.

No References or Customer Testimonials

A credible supplier should be able to provide client references or case studies that demonstrate their experience and customer satisfaction.

If a supplier cannot furnish this information, it may indicate a lack of experience in the industry or the presence of dissatisfied customers.

Testimonials and references serve as valuable indicators of a supplier’s reliability and quality of service.

When evaluating potential suppliers, seeking out this information helps ensure that you are partnering with a reputable company that has a proven track record of delivering quality products and customer support.

Do They Use Substandard Materials or Designs?

Low-Quality Rare Earth Magnets

Some suppliers may cut costs by using low-grade neodymium or dysprosium alloys in their magnets.

This practice significantly reduces the efficiency and lifespan of motors, leading to subpar performance and increased maintenance needs.

It is essential to ask for detailed magnet material specifications to ensure that the magnets meet the required performance standards.

High-quality rare earth magnets are crucial for achieving optimal motor performance, and settling for inferior materials can compromise the entire system’s reliability and effectiveness.

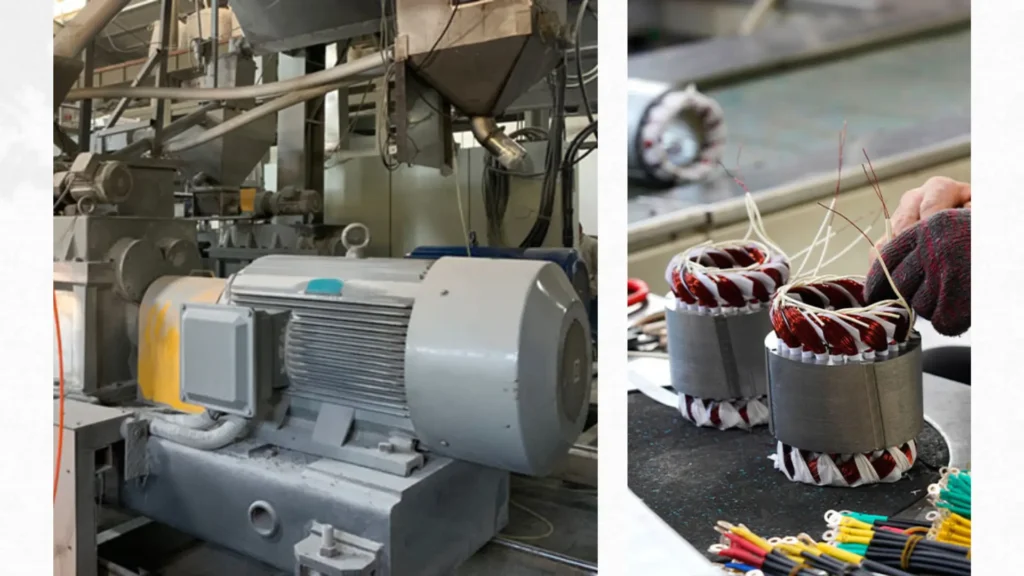

Poor Insulation and Windings

The quality of insulation and windings plays a critical role in the durability and efficiency of electric motors.

Suppliers that use cheap copper-clad aluminum (CCA) windings or low-grade insulation may expose motors to overheating and premature failure.

These components are vital for maintaining electrical integrity and thermal performance.

Always ensure that the supplier uses 100% copper windings and high-grade insulation materials. Investing in quality components not only enhances motor performance but also reduces the risk of costly failures and extends the operational life of the equipment.

Lack of Customization Options

Reputable suppliers typically offer a range of customization options, including custom voltage, power ratings, and mounting designs to meet specific application needs.

If a supplier only provides generic models without the ability to customize, it may indicate a lack of true engineering expertise and flexibility.

Customization is essential for ensuring that the motors are well-suited to unique operational requirements.

Working with a supplier that understands your specific needs and can provide tailored solutions is crucial for achieving optimal performance and efficiency in your applications.

Also Read:

How Rare Earth Magnets Boost Efficiency in Permanent Magnet Synchronous Motors

Conclusion

Selecting the right rare earth Permanent Magnet Synchronous (PMS) motor supplier requires careful due diligence.

Key factors to watch for include missing certifications, suspiciously low prices, poor communication, unverified production capacity, and the use of substandard materials.

By avoiding these red flags, you can secure a high-quality motor that delivers long-term performance and efficiency.

Conducting thorough research and asking the right questions will help you make informed decisions that align with your operational goals.