There are some very critical features of PMSM motors that make them stand apart from other motors.

High efficiency, with figures commonly exceeding 90%, brings in huge energy savings for those using the motors.

Due to their compact design, they can simply be fitted in even the smallest spaces, making them additionally versatile in terms of usage.

In general, PMSM motors show fewer maintenance considerations compared to other types of motors-with fewer moving parts, reduced downtime and repair costs.

This is why so many companies choose PMSM motors; they aim for more business with less expense.

PMSM motors are very flexible in their range for applications over the industrial domain for a variety of industries.

Most usually applied in automation systems, into robotics, into manufacturing processes, and in all structures related to speed and torque-control motors.

In the same vein, in the automotive field, they are placed in electric vehicles with effectual results in energy efficiency and torque magnitude.

In manufacturing, they steer conveyor systems and CNC machines, making it possible to operate even the most minor.

As adoptions are happening in organizational automation and new technologies, more demand is forecast to rise for PMSM motors.

And More:

- Overview of Permanent Magnet Synchronous Motors in China

- Top 10 Permanent Magnet Synchronous Motor Manufacturers in China

How Do PMSM Motors Work?

Basic Operating Principles

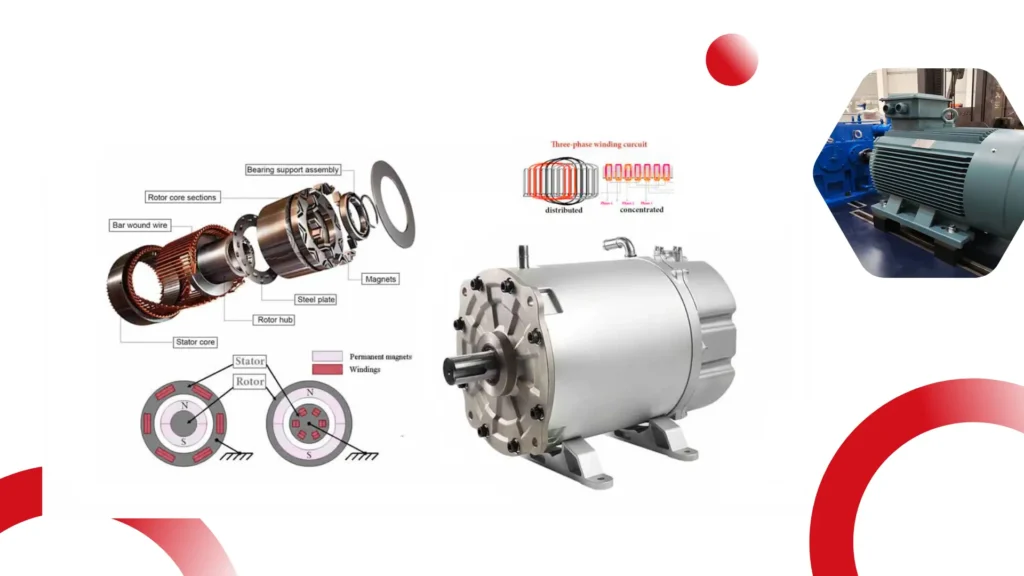

The permanent magnet synchronous motor (PMSM) works on the principle of electromagnetic induction.

A rotating magnetic field is formed when an electrical current is caused to flow in the stator windings.

The rotor equipped with permanent magnets interacts through this rotating field, causing it to rotate.

The synchronous feature of the motor implies that the rotor follows a rotating magnetic field and hence no slip is present. Also, that will be contributing to high efficiency.

This allows for working out the desired precise speed and torque for the electric motor which is critically required for a variety of industrial processes.

Various Types of PMSM Motors

Basically, PMSM motors are classified into two types: surface-mounted and interior.

A surface-mounted motor has the magnets mounted on the surface of the rotor giving torque and efficiency with high potential, and such motors are highly suitable for applications where high-performance compact designs are made necessary.

The other types, called interior PMSM motors, are where the magnets are contained within the rotor, and this gives improved torque at lower speeds and enhanced thermal performance.

It helps in the selection of the right motor as per the most excellent applications and operational concerns of the businesses.

Control Systems and Technologies

It is well known that advanced control systems are vital to achieving improved performance of PMSM motors.

Vector Control and Direct Torque Control technologies provide precise control of motor operation to achieve quick response and efficiency.

Vector control allows the variation of the speed and torque of the motor, while direct torque control instant torque response is good for applications that require high acceleration and deceleration.

In the industrial fields, these control technologies go a long way in beefing up overall efficiency.

Why Choose PMSM Motors for Your Business?

Energy Efficiency

One advantage of choosing PMSM motors is the high level of energy efficiency they have.

Almost all companies are experiencing a problem of rising energy costs, which leads to almost all organizations finding ways to reduce their electricity bills.

PMSM consumes noticeably less energy compared to standard motors, so it is possible to limit spending on operations.

This advantage also has repercussions on the sustainability of a company’s policy. It translates into a saving of energy by reducing the power consumption.

Low Maintenance

One issue with PMSM is it has fewer moving parts compared to a traditional induction motor.

It results in lesser requirements of maintenance wear and tear. This prolongs the operational life of the equipment, which in turn reduces the average frequency of repairs made.

For any business, this means minimizing downtimes and maintenance outlays, hence allowing it to utilize resources more efficiently.

It is possible, too, for companies to allocate these maintenance budgets to other areas that are very critical, thus enhancing overall productivity.

Adaptability and Versatility

PMSM motors find application in various forms for numerous small applications, as well as very elaborate industrial processes.

Consequently, such motors are also expected to be used when expanding and diversifying operations.

Whether the system is one aimed at automation of factory processes, high-precious robotic applications, or event management’s motive power, customization is possible because one such PMSM motor can be specifically adapted to meet the requirements placed upon it.

What are the Economic Benefits of Using PMSM Motors?

Benefits on Energy Bills

Due to such high efficiency of a PMSM motor considerable energy cost savings acrue.

Such considerable savings can leave a noteworthy impression on any industries, which would find it difficult to implement high-margin savings for overall profitability.

A business that installs and implements PMSM technology can expect to see some decline in energy bills as funds can be redirected from energy costs to other critical areas of operations.

In the long run, savings in an accumulated energy bill can be a very attractive financial encourager to move towards use of such motors.

Return on Investment (ROI)

There is a very strong rate on return when businesses invest on PMSM motors.

Payback periods are very short in these cases since the motors are not only durable but require very low maintenance.

Lower operational costs and higher efficiency add a very favorable return on investment as well.

For companies that put a high premium on long-term sustainability and cost-unbeatable, PMSM motors represent such financial opportunities that widen the company’s operational breadth.

Competitive Advantage

PMSM technology is being adopted by many companies to improve the efficiency of their operations and the quality of their products, positioning them advantageously in the market.

Efficiency in the operations drives faster production times which make a big difference in customer satisfaction – and of course in the fast-paced industrial environment of today.

Using PMSM motors takes not only the current state of productivity higher than that but also leaves an organization very advantageous for further growth and competitiveness positioning.

How to Choose the Right PMSM Motor?

Determining Your Requirements

It will be necessary to identify all that is needed to be done before even selecting a PMSM motor.

Particularly, considerate the torque, speed, and load capacity of the motor in agreement with the requirement.

Knowing the environment in which the motor is to work and type of application will help in selecting a right type of motor required for the best performance. Hence, this becomes the area on which to base informed purchasing decisions.

Consultations with Professionals

This would involve talking to industry professionals on the subject choice of a PMSM electric motor part in the future.

They would help you navigate through the intricacies of motor specifications and performance requirements.

The experience would then open up your eyes and mind about various motor types and their fit into an application you could have.

They make sure you know exactly what it is that you are deciding that will increase operational consequences.

Value Additions to a Supplier Evaluation

It always would be very important to select from a pool of several reliable suppliers with sound records in supplying excellent PMSM motors.

Reputation, customer service, and services after sales evaluations will ensure that you can bank on satisfying experiences each time you shall purchase something for your specified or localized needs.

Trusting an excellent supplier will also get you guided through the process of selections and offer administrative support to your equipment after you have made a sale.

Supplier quality assessments should be implemented to assure you obtain the product that you expect and help you with what you actually need for simultaneous functions.

What are the Future Trends in PMSM Technology?

Magnet Materials of the Future

Searching into magnetic materials will bring to new and stronger magnets that are lighter.

Such significant strides increase the overall performance level of PMSM motors.

An aside, such progress may lead to still higher efficiency and cost reduction.

The coming of novel materials is as likely to open the space to further refinement in the practice and application of PMSM motor making them very attractive to industries seeking to assure their performance.

Intergation with Smart Technologies

In future, PMSM motors will be interfaced with smart technologies like those that incorporate IoT and AI.

It brings monitoring in real time, with forecasting maintenance which provides great intensification of operational efficiency.

Utilizing the data analytics, companies can maximize motor operation and an accurate anticipation of maintenance needs, minimizing downtime and eventually increasing overall productivity.

Eco-friendliness and Sustainability

PMSM motors now emerge as the burgeoning attractions in the energy efficiency and lower environmental impact of industries today.

Businesses are shifting for more sustainable practices, into energy-efficient and environment-friendly exports.

It will also contribute to energy savings and responsible corporate practices as much as it is for the environment.

Thus, for those that are hang-up on their company’s sustainability, PMSM motors are indeed a smart move.

How Can PMSM Motors Boost Your Industrial Operations?

Enhancing Production Efficiency

The employing PMSM motors in industrial operations increases production rate and shifts shorten as a result.

This accurate control ability allows for easy integration with other automation systems this then will bring much increase in the level of efficiency that will be met in the overall production.

By maximizing outputs and minimizing inputs, businesses could attain profitability levels much higher than what they could have achieved using some other technologies and could also be equal to the market demand.

Improving Product Quality

The precision resulting from using PMSM motors in a process should bring about assurance with regard to quality developed in manufacturing.

Steady-speed control and consistency in performance bring to zero defects during production; thus, customers will be most satisfied.

Companies should differentiate themselves by putting quality as their priority in a highly contested market example, through building customer care and ensuring the clientele keeps coming back to repeat business.

Advancing Automation Efforts

PMSM motors are crucial when it comes to automation systems since they are at the heart of any particular automation system.

The reliability and performance capability PMSM comes with, is what one needs in such a prevailing situation for automated operations.

As in the coming days the industries are slowly surrendering to automation, it will take center stage and streamline the process reducing labor costs.

Those motors have some of the highest performances and are set up to support and to drive whatever will come from advanced automation initiatives that are going to be drawn up within the industry in the near future.

What Should You Know About PMSM Motors in China?

Market Overview

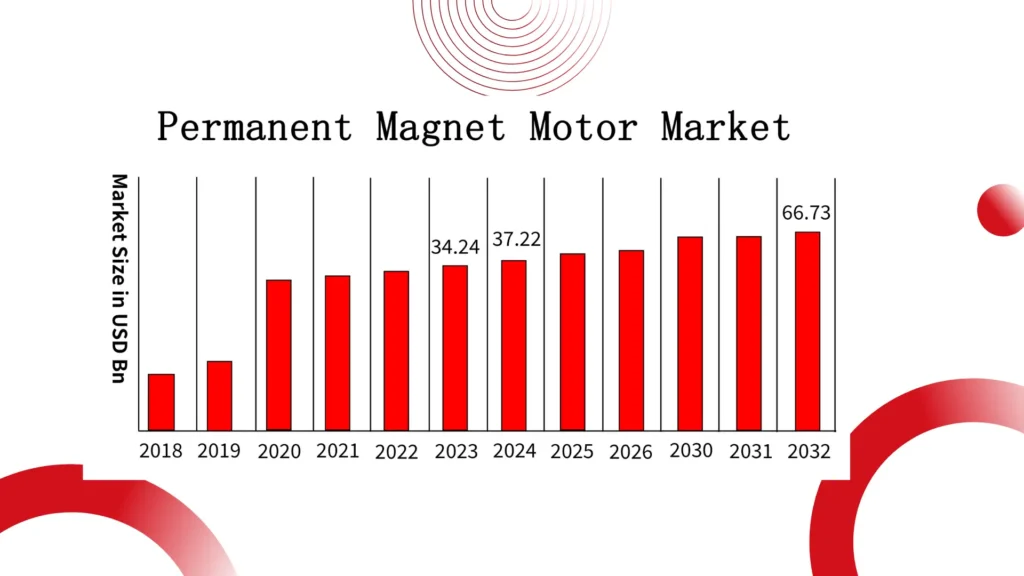

China has a growing Permanent Magnet Synchronous Motor (PMSM) market driven mainly by ongoing industrialization and advances in technology.

Investment in infrastructure and factories is under way in China, so demand for more efficient and reliable motors is climbing.

Studying this landscape provides businesses new links to opportunities and trends in the industry that is constantly changing.

Government Regulations

Issues of regulation and standards of motor manufacture and use should be known so that companies, especially those doing business in China, can comply with proper protocols for successful operations and market entry. Changes in market dynamics mean that companies adjust some strategies, but keeping up-to-date with changes in policy is crucial.

Local Supply Chain Dynamics

Supplier networks to local suppliers will streamline how supply chains are managed in China.

A streamlined supply chain will decrease lead times and improve service, so that businesses will always have what they need, whenever they need it.

By utilizing resources close at hand, companies can improve the way they respond to market requirements.

Conclusion

PMSM machines bring with them advantages that potentially mean great benefits to companies that use them.

They are energy-efficient and low maintenance and have adjustable speed operation in a way that they can easily suit the needs of a business.

Knowledge about PMSMs and their advantages as well as practical applications allows a business to determine which is then supposed to improve operating efficiency and alter operational expenditures effectively.

Embracing new technology like PMSM machines and embarking in enhanced functionalities at industries will pave more competitive grounds.