Permanent magnet motors are thus constructing an entirely new generation of electric motors.

These motors generate their field using permanent magnets, unlike their predecessors that have windings and electromagnets.

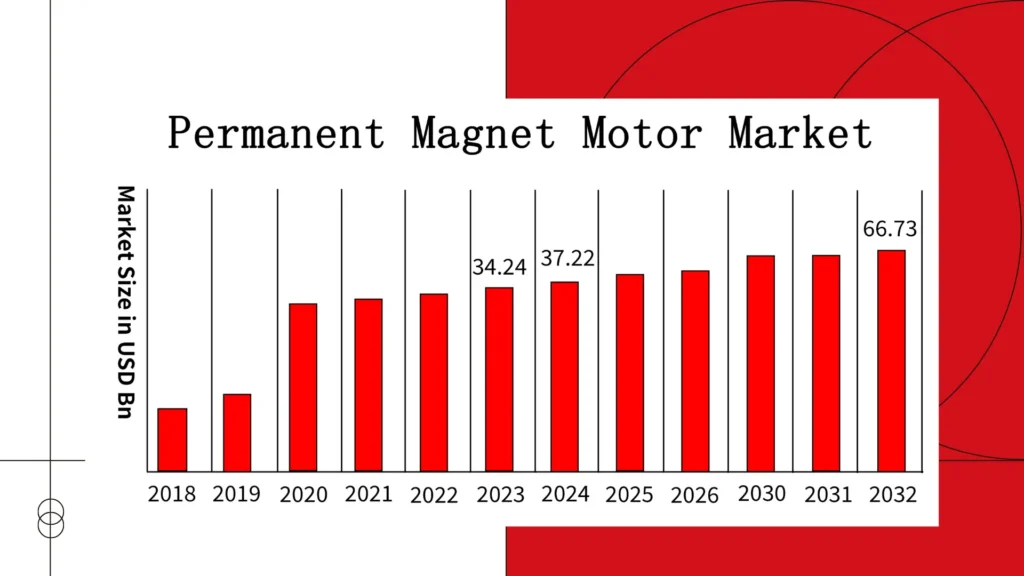

It is indeed gaining massive ground in many industries, including automotive, robotics, and renewable energy.

The electric current flowing through the coils generates the magnetic field that interacts with the permanent magnet’s fixed magnetic field, establishing rotor rotation.

As a result, speed and torque can be very finely controlled, making them highly suitable for outstanding performance applications.

Some major benefits include high energy efficiency, resulting in low operating costs and compactness of design, facilitating easier integration with existing systems.

At the same time, they have lower noise levels and maintenance problems because of fewer moving parts, which increases reliability and lifetime.

And More:

High-Performance Permanent Magnet Motors Made in China for Commercial Applications

The Growing Demand for Electric Drives

What Are Electric Drives?

Electric drives are systems meant to control the working of electric motors; they are used to convert electrical energy into mechanical energy while giving a facility for very accurate control of the speed, torque, and position of the electric motors.

It plays an important role in many applications from industrial machines to consumer electronics for an efficient and reliable use.

Increase in Demand

This increase in demand has continued even into the last few years due to growing national pushes towards energy efficiency and sustainability as well as improving industries’ attempts at lessening the carbon footprints imposed by industrial operations in adherence to what environmental regulations demand.

The electric solutions have become even more attractive as approaches for measuring up these requirements.

Electric drives with high-efficiency motors were developed for better operation through this goal.

The trend happens in the common business with a prominent example as automotive, manufacturing, or renewable energy.

Benefits of Electric Drives

Some of the reasons for the use of electric drives are high operational efficiency along with reduced energy use, better control over the motor functions, improved performance, reduced wear and tear of the equipment, and the additional life of the equipment.

Optimizing energy use can bring down the costs of operations significantly making such investments truly valuable for any business.

China’s Role in Motor Manufacturing for Electric Drives

Manufacturing Excellence

China does not only lead the entire globe when it comes to manufacturing electric motors, but also high efficiency permanent magnet motors for electric drives.

Given its production capacities and huge, skilled labor force, the country can manufacture motors on scale, thereby sustaining the brisk, global demand.

Beyond that, the reputation of Chinese manufacturers lies in their ability to manufacture high-quality products on time, thus harmonizing their intuitive partners who want to be effective in applying electric drives.

Technological Innovations

Chinese manufacturers tend to make advancements in the design and production of motors.

R&D investments continually churn out innovations with the aim of increasing efficiency and improving performance in permanent magnet motors.

These innovations can still be agreed as reducing the production cost by using fewer components to enable high-quality motors to reach a greater number of clientele across industries.

Quality Assurance

At the same time, improving product quality while achieving competitive advantage through affordability is the theme of most Chinese manufacturers.

Most of these companies have secured international certification, meaning that the respective products pass performance and safety benchmarks.

Therefore, customers are assured of making an investment into reliable, durable motors for their electric drive applications.

Understanding Efficiency in Motors for Electric Drives

Motor Efficiency Definition

Motor efficiency defines the ratio of output mechanical power to the input electric power consumed.

High efficiency motors for electric drives convert much larger portions of electric energy into usable energy, thus reducing energy consumption and operating costs.

Knowledge of motor efficiency helps businesses to manage their energy and costs’ consumption related to electric drive systems.

Importance of High Efficiency

High efficiency motors save energy as well as generate less heat.

In the installation of energy-intensive motors, this would lessen the cost as well as the premises requirement for cooling coil systems, given the lesser heat generated.

In applications of continuous service, it becomes critical in terms of performance, energy savings, and to some extent helps toward minimizing the energy utilization.

Rating Measurement

Motor efficiency is measured with standards such as International Efficiency (IE).

This is before classifying motors into various efficiency categories, making it easy for the buyer to identify his motor for electric drives in accordance with the most efficient alternatives.

Therefore, they help in making the correct decisions for businesses with energy saving objectives.

Selecting the Right Permanent Magnet Motor for Electric Drives

Assessing Needs

Ask yourself whether you need a permanent magnet motor for electric drives. Next step, evaluate your needs.

Knowing these critical factors will reduce usage areas and help you select the most appropriate motor, which can then ensure maximum performance and efficiency for your drives.

Understanding Specifications

Motor specifications are essential to understanding making a selection for electric drives.

Most commonly, these include torque ratings, voltage levels, efficiency, and dimensions.

With a clear understanding of these elements, it becomes possible to make the best choice and ensure that the product fits with preexisting conditions while meeting operational requirements.

Consulting with Experts

In considering the best possible motors for electric drive applications, engaging either an in-house industry specialist or supplier usually holds the answers to motor options available externally.

Discuss with experts on technical specifications and motor selections that will match your objectives and cater to you’d needs right through to purchasing.

Briefly, it will save much time and money while helping guarantee an overall right decision.

Cost Considerations

Competitive Pricing

Importing permanent magnet motors from China is a cost-effective solution for industries.

Cost-producing and productive processes in manufacturing have led to more competitive pricing of these motors compared to another country’s alternatives.

This affordability of high-quality motors makes them available to a wider audience from small to big businesses.

Long-Term Savings

The purchase of high-efficiency permanent magnet motors can bore into tremendous savings in the long run.

Lower energy consumption would place an immediate price tag on power bills, while durability would minimize the number of replacements and maintenance that have to take place in the normal lifetime of the motors.

The savings thus accumulate over the years to make a very reasonable return on investment and thus facilitate resource allocation for the business.

Value for Money

Chinese manufacturers have succeeded in producing a wide variety of permanent magnet motors that would deliver outstanding performance at very reasonable prices.

This affordability-to- quality ratio ensures clients do get value for their money.

With the correct motor selection, companies can improve their operations without compromising their budgets.

Applications of Permanent Magnet Motors for Electric Drives

Automotive Industry

These motors are mostly used for electric and hybrid vehicles among various applications in the automotive sector.

Because of their high efficiency and high torque, these motors serve as a perfect solution to power electric drives in a vehicle and significantly increase the range and performance of the vehicle.

These types of motor will continue to be in demand as automakers shift from conventional combustion engines to the growing demand of electrification.

Renewable Energy

In renewable energy applications – notably those for wind turbine operation and solar tracking – permanent magnets have a crucial role.

Such systems optimize energy capture and conversion and contribute significantly to the complete renewable energy system’s efficiency.

As the world turns to sustainable solutions for energy, it increasingly becomes important for this sector to rely on very efficient motors in support of the changing climate and the need to achieve cleaner energy.

Industrial Automation

Permanent magnet motors are robustly relied on in such industrial applications as robotics and conveying.

By developing performance as a result of accurate control coupled with the very high torque, they operate independently on all production lines.

Maximizing these motors in production is one step towards putting any company on the quality scale of production while cutting costs and enhancing productivity.

This is what makes such motors an area of investment for any modern industry.

Conclusion

High-efficiency permanent magnet motors sourced from China have numerous benefits like enhanced energy efficiency, durability, and cost-effectiveness.

They serve within the future of electric solutions across industries toward sustainability and efficiency in businesses.

In the face of continuous change in the industries, new technologies such as permanent magnet motors must be embraced.

These will be the closest step to greener and more efficient operations and competition among other businesses.

For those organizations thinking of switching to permanent magnet motors at the moment, it’s the right time to explore sources.

Assess your needs, talk to professionals, and begin to enjoy the benefits provided by the new features of these motors.

Putting money into permanent magnet technology today may return big dividends in the future and set the company for progress in an energy-conscious world.