In parts pertaining to the use of permanent magnets, an electric motor, as differentiated from the electro-motor, possesses permanent magnets for forming a field through which they can be moved.

They are relatively efficient and compact which would adequately fulfill industrial requirements, well solvent in most applications without much maintenance.

Permanent magnet motors act on the principle of electromagnetic induction, where an electric current flows through its coils and interacts with the magnetic field created by the permanent magnets in the motor rotor, causing it to spin.

This little principle, however, provides effective speed and torque control driving a motor for demanding tasks in industrial applications.

And More:

High-Performance Permanent Magnet Motors Made in China for Commercial Applications

Importance of Torque in Industrial Applications

What Is Torque?

The amount of turning force that a motor can apply or generate is defined as torque.

This parameter is important for establishing a performance parameter of the motor applies even more when the operations pertain to heavy loads and work machinery optimally.

Hence, it is very important to understand torque for a specific selection of motors for a specific industrial application.

Why High Torque Is Important?

High torque is needed in any industry which requires heavy lifting, accurate movement, or very fast acceleration. These motors can be started under load without stalling and thus produce jerk-free operations with less chance of machinery getting damaged. This is needed in industries like manufacturing, automotive, and construction.

Sectors Benefiting from High Torque Motors

High-torque motors can improve productivity as well as efficiency in several industries.

Examples include the use of high-torque motors in both conveyor systems and robotic arms in the manufacturing sector.

The automotive industry typically uses high-torque motors on electric vehicles to gain better efficiency from the motors.

Renewable sources of energy, such as those harnessed from wind turbines, are now increasingly being dependent on these motors to process energy production optimally.

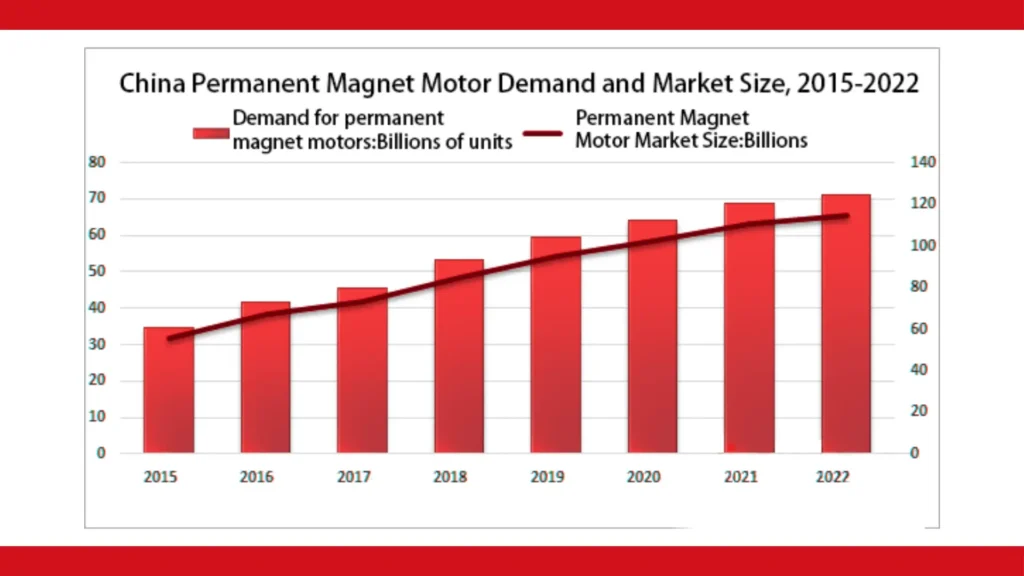

China’s Role in the Permanent Magnet Motor Market

Modification Capabilities

China has emerged as the world’s top manufacturer of permanent magnet motors.

Today, advanced production lines and skilled employees in China have made it possible for the industry to manufacture superior quality motors at scale.

This capability helps the companies to keep pace with increasing demand, in addition to maximizing cost-effectiveness.

Technological Innovations

They lead because they are up-to-speed when it comes to research and development in motor technology. The advancements are toward newer, better, and much more efficient and powerful motors that complement better performance with less energy consumption, making them viable alternatives in many industries.

Quality Standards and Certifications

The manufacturers make sure their products are in conformity with international quality standards and certifications so that they can compete with their counterparts throughout the world.

It makes the motors highly reliable and durable for different industries because of strict international requirements.

Their certification further enjoins customers with organizations like ISO and CE.

Key Features of China-Made Permanent Magnet Motors

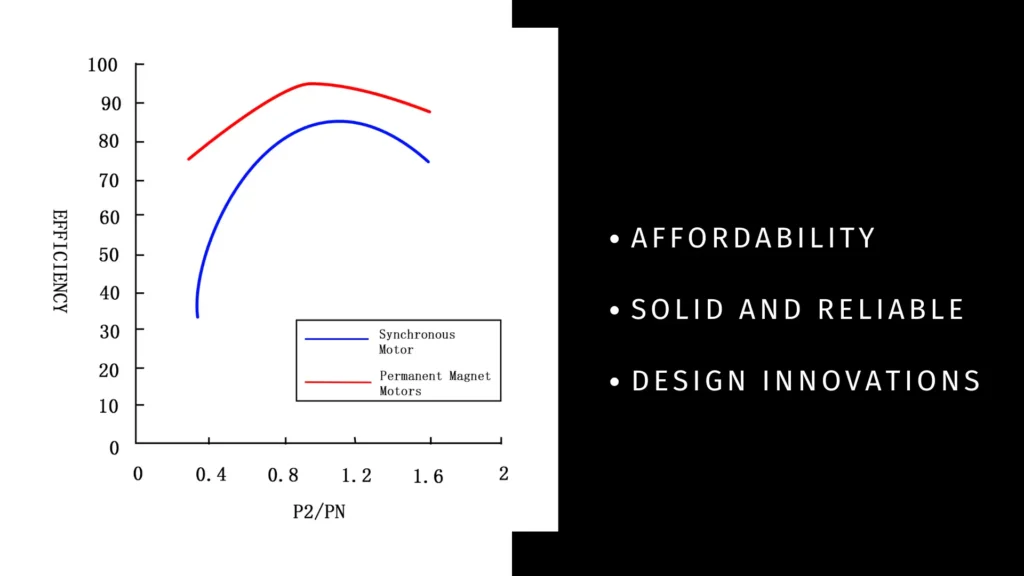

Affordability

PM motors made in China are very efficient (usually up to over 90%) and cheaper to run than ordinary motors.

They are also environmentally-friendly motors for industries with reduced energy consumption and carbon footprint.

Its performance is quite steady regardless of the changes in the load; thus, it is considered to have an optimum operation.

Solid and Reliable

These motors are engineered to perform extremely well under tough industrial conditions.

This provides superb durability and reliability by a sturdily constructed product with high-quality materials.

This strong reliability reduces standstill and costs for maintenance, enabling smooth operation of companies.

Design Innovations

Continuously innovating on motor design in China provides features to be added for better performance and usability.

Thus, many of them can include an integrated sensor for real-time monitoring of the motors in the future, predictive maintenance, and improved operational efficiency.

Cost-Effectiveness of China-Made Motors

Competitive Pricing

One of the main advantages of purchasing China made permanent magnet motors is never their competitive price.

From lower production costs and more efficient manufacturing, such motors usually cost a fraction of that which they cost at other countries, making them available to a wider variety of applications.

Savings in the Long Run

Long-term savings are quite possible when you invest in high-efficiency motors. Less energy consumed means lower electric bills.

With these motors, there is less frequent replacement because they last longer and thus incur lower maintenance costs.

Over a couple of years, all these savings can easily offset the initial expense.

Value for Money

These motors provide excellent performance in terms of value derived for the customers’ money.

The client receives really high quality, efficient motors at really affordable rates. Such affordability combined with performance makes such company dynamic.

Applications of High-Torque Permanent Magnet Motors

Precision Manufacturing Machines

From conveyors, pumps, to compressors, it uses permanent magnet motors in almost all types of manufacturing equipment.

They are provided with high torque in delivering power efficiently during operational turns, hence reducing cycle time and maximizing output in a factory setting.

Automobile Industry

Essential to Electric and Hybrid cars is high-torque permanent magnet motors.

These serve the purpose of providing acceleration power and hill climbing at the same time assuring energy efficiency all to make the electric drivetrains perform highly.

Renewable Energy Solutions

High-torque motors find application in renewable energy – wind turbines and solar energy tracking systems.

These motors are optimized for energy capture and conversion, playing a major role in switching to an energy source sustainability.

How to Choose the Right Motor for Your Needs

Identify Your Needs

It is important to determine your individual needs before you buy a permanent magnet motor.

You must know what load capacity, speed, and environmental conditions apply to the use.

By understanding these parameters, you can select the appropriate motor for your application.

Understanding Specifications

Understand the principales of motor specifications, such as torque-ratings, efficiency and size dimensions, with which one can make informed decisions on compatibility of motor with existing machines.

Consult an Expert

Above all else, consult with other motor specialists or manufacturers before purchasing a motor.

They know and understand much more about your needs and therefore, will benefit you in your decisions whilst ensuring that you make the correct choice for your company.

Conclusion

Permanent magnet motor has a better efficiency, durability, and cost-effectiveness when made in China.

High Torque generation makes this an important component of various industries to improve productivity and performance.

Even as the industrial landscape finds itself revolving, one must embrace novel innovation on the application of permanent magnet motors.

They represent efficiency when it comes to fixtures in relating to power sources and objectives in which businesses can compete in a growing fast-paced market.

Thus, businesses should begin research into the new world of permanent magnets.

The time is now to analyze suppliers, understand their needs, and capitalize on the benefits of these advanced motors.

From this point forward, investments made in permanent magnets technology will result in significant payoffs later.