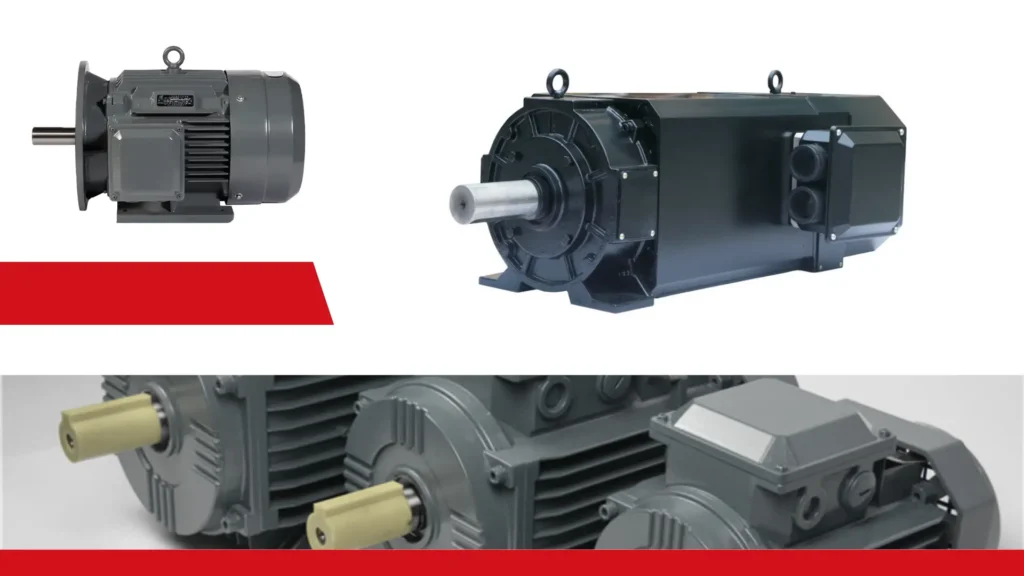

Permanent Magnet Synchronous Motors. It’s an electric motor that operates by incorporating permanent magnets within the rotor.

Conventional motors make use of the electromagnetic fields produced by a coil; however, PMDC motors exploit the magnetic fields produced by these permanent magnets in order to form rotational movement.

This is expected to show greater operational efficiency and enhanced control.

PMDC motor consists of an array of pivotal components such as rotor, stator, and control system.

The rotor is endowed with permanent magnets whereas the stator hold coils which establishes the rotating magnetic field of the motor when fed by energy.

The control component is responsible for an optimal application to power supply to the motor.

PMDC motors perform by synchronizing the movement of the rotor with the magnetic field rotation that the stator materializes.

On energizing the stator coils, a magnetic field is developed, which reacts with the permanent magnets within the rotor, setting the rotor in motion.

For this reason, the efficiency and performance of PMSMs are a perfect fit for various applications.

It finds utility in various applications, such as driving vehicles or being attached to heavy machinery, harnessed for robotics, central to heating, ventilation, and air conditioning (HVAC) system as well as serving industrial purposes.

There are numerous applications that can be ameliorated by this technology, as the generating capacity of these motors at those low-speeds is notably high and they remain highly efficient even under wide-ranging operational environments.

Why Choose Permanent Magnet Synchronous Motors Over Other Types?

Optimized Performance

PMSMs are one of the most efficient units because usually, they perform at efficiency rates of 90% or above, which ensures significantly less energy consumption in comparison to induction motors and results in lower electricity bills and reduced carbon emission.

Consistency of Performance

This is because PMSMs have continued to perform with stability within considerably wide ranges of speeds and loads.

High-torque generation and persisting speed stability make these motors very appropriate for applications that need precision and reliability; for example, robotics and CNC equipment.

Low Operating Costs

As a natural consequence of their high efficiency and relatively low energy consumption, PMAC typically tends to incur lower operating costs over its life.

There could also be fewer energy losses, thus leading to less heat generation that could translate to lower cooling costs and, in effect, a longer motor life.

Space Efficient

PMSMs could be generally smaller than most other motor types like induction motors, and therefore, better admire the proper and space-saving design attribute since they allow more flexible engineering possibilities in installation even at already tighter space limits, which also makes them ideal for applications with hardly any space for equipment.

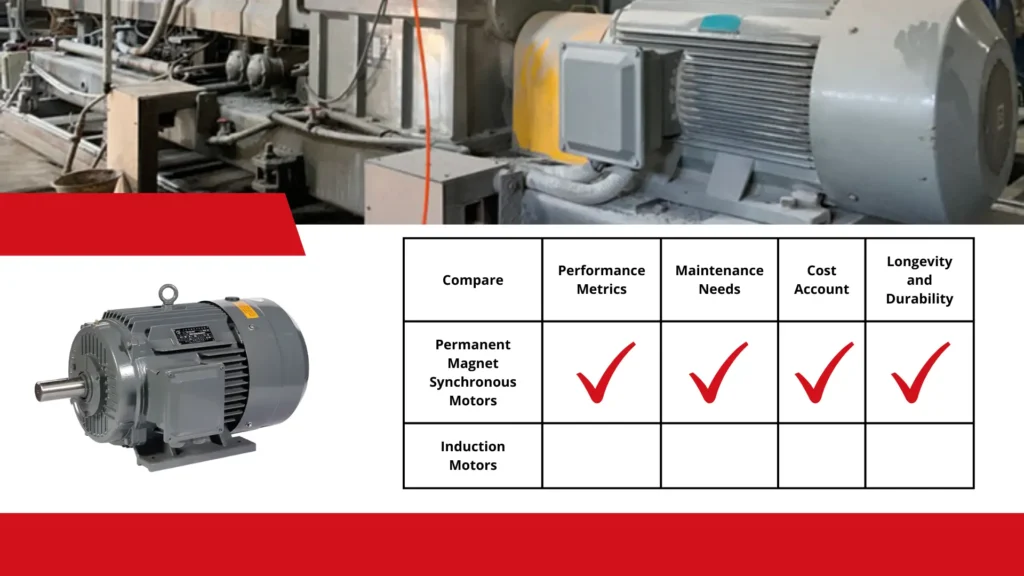

How Do Permanent Magnet Synchronous Motors Compare to Induction Motors?

Performance Metrics

PMSMs are often better than induction motors in terms of efficiency and agility.

They provide a substantial amount of torque even at low speeds.

These are highly preferred for applications requiring quick accelerations and decelerations.

Maintenance Needs

PMSMs tend to require lower maintenance compared to induction motors because they do not have as complex a construction, which necessitates brushes.

Less maintenance can thus lead to less expense and downtime-and this generally enhances overall operational efficiency.

Cost Account

Even after expensive initial cost, PMSMs still prevail over the induction motor because of maximizing energy savings and maintenance savings.

Over time, the total cost of ownership can typically be significantly less for PMSMs.

Longevity and Durability

Compared to induction motor, PMSM can boast relative longevity because of its sturdy basic design and relatively low heat generation.

Thus they are reliable for rough and critical applications where durability is paramount.

What Are the Key Benefits of Using Permanent Magnet Synchronous Motors?

Power Efficiency

PMSMs generate great savings in energy costs due to their effectiveness in addressing operational costs and future sustainability goals.

These design setups eliminate wasted energy and thus are greener alternatives.

Higher Noise Levels

These motors operate more silently compared to other conventional motor types and, therefore, are useful in noise-sensitive environments including residential or health care schemes. This subsequently makes user satisfaction and comfort possible.

More Controlled Torque and Speed

These PMSMs provide unmatched torque and speed control capability, which actually facilitates utmost accuracy related to various kinds of applications.

The main application here is in exact-motion-related industries, such as automation and robotics.

Guaranteed Reliability

PMSMs are more reliable as compared to other motor types with fewer moving parts and a simpler design that gives rise to robust performance under varying conditions, ensuring a smooth and seamlessness of operations.

And More:

Key Features of Permanent Magnet Synchronous Motors (PMSMs)

Cost Savings on Permanent Magnet Synchronous Motors

How to Select the Right Permanent Magnet Synchronous Motor for Your Needs?

Requirements of Application

What should be well known while selecting this PMSM for the specific application is the technical requirements including load kind, velocity, and surrounding operational environment that should be identified while motor selection was to take place.

Size and Power Rating

In size and power rating, the right size may be judged by the best performance of the motor.

A small motor will fail to satisfy demands while a larger motor may create a bad effect through inefficiencies. Sizing ensures it is optimized with the right operating area of the motor.

Environmental Conditions

Consider all external factors, upon which it appears that the motor’s efficiency will also be based.

For instance, consider whether the motor ought to be used at extreme temperatures or in moisture.

Budgetary Controls

On the other hand, investing in more quality is necessary in defining a budget. Evaluate the TCO, composed of all purchase, energy, and maintenance needs, so as to fit a PMSM in line with the financial contours.

What Are the Latest Innovations in Permanent Magnet Synchronous Motor Technology?

Emerging Materials

Recent advances in material sciences have allowed the development of stronger and lighter permanent magnets.

These include new materials to make better-performing motors while also making them more efficient and lighter.

Motor Technologies-Consisting of Smartness

Smart technologies are now incorporated into PMSM systems that were started with the advent of Industry 4.0 to enable real-time monitoring and diagnosis of failure thus become an efficient tool to reduce downtime and allow for predictive maintenance.

Injecting the Energy of Renewable

This can allow PMSMs to come into renewable energy systems, such as power from both wind and solar energy.

With regard to their high degree of efficiency and reliability, these machines are perfect for converting and managing power in these applications for a sustainable energy future.

Automation Developments

Automation is becoming an inevitable phenomenon prevailing in various sectors; useful in leading-edge robots and systems designed for automatic performance and precision, PMPS is taking this direction towards utmost importance.

How Can Permanent Magnet Synchronous Motors Improve Your Operations?

Raised Productivity

PMSM may significantly boost productivity because of its high efficacy and stability in operation.

Working at its best, recessed downtime and a lot of it later improve the flow of work at large.

Process Optimization

Precision control, courtesy of PMSM, makes sure that a process is streamlined in manufacturing-applicable as well as in other avenues of technical know-how.

It tends to add up to effectiveness; waste reduction occurs in the least possible times achieved with maximized utilization.

Elevated Product Quality

Taking up improved quality product, torque, and speed control are some definite ways PMSM could be used for the greatest advantage.

This means the unit will regularly and reliably produce the highest quality of product to eventually satisfy the most stringent customers.

Sustainability

PMSMs fall in line with good business practices for their energy efficiency, thus having an overall positive impact on the environment.

Through this reduced energy consumption, businesses can also attain regulatory and corporate sustainability goals.

What Should You Know About Maintenance and Support for Permanent Magnet Synchronous

Motors?

Maintenance Essentials

Contrary to other motor types, PMSMs require little maintenance, but checks must remain consistent.

Routine checks and monitoring will provide enough room for potential problems to be rectified before they get serious for ensuring durability.

Common problems Troubleshooting

They should know enough about issues like over-heating or declining performance while it gets brought to their attention.

It goes further if lower-level support groups can provide a simple reference for them to work on their productivity.

Professional Service Professionals

Employing the usage of professional service providers may establish a professional relationship ensuring that the PMSMs remain effective and reliable.

Expert personnel will then give advice for the needs specific to the process and deliver solutions.

Warranties and Agreements

The warranty and service agreements should be seen to be evaluated from the warranty holder’s title, in buying the PMSM.

It ensures a good amount of peace should be had and total investment for the long te

Conclusion

In conclusion, Permanent Magnet Synchronous Motors (PMSMs) are the buzzword in the industry.

And why not? With unmatched, superb technology, PMSMs have an upper hand over other, old-school conventional options of energy savings, consistent performance, and lesser maintenance.

The usefulness of PMSMs then becomes progressively more enhanced, especially as industries globally scale up their automation and sustainable practices.

Right selection of a PMSM for its application means it can help industry players enhance productivity, streamline processes, and improve product quality.

This upgrading of technology is another guarantee that the product is sticking with the times in terms of new materials and invention of new technical capabilities that, among other things, are likely to be focused on engineered materials.

Not only does investing in this type of engine system mean smooth operations, but it also indicates the concordance of broader sustainability goals, which then pinpoints a strategic vision of things that economically advanced establishments must keep an eye on to stay ahead.

Reward yourself for such investments because you see the future of your operations.